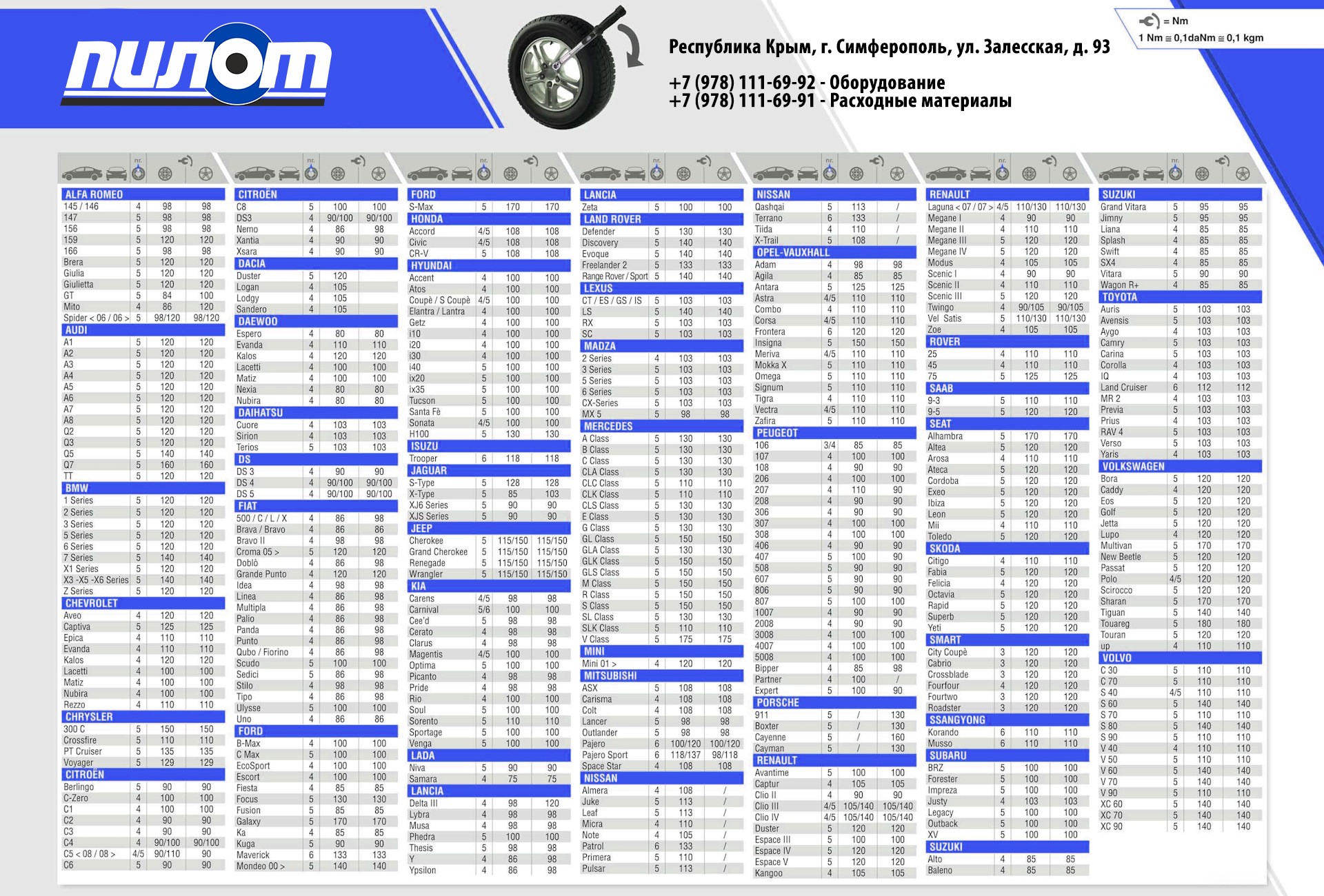

Main Wheel Nut Torque Specifications

Content

As an automotive technician, you will most likely master the skill of using the correct torque to install lug nuts.

Every automotive technician job entails something a little different, but there are some things every mechanic should know. One such service is the installation of clamp nuts using the correct torque (measured in ft-lbs). To do this, you will need a torque rod, impact and torque wrench, and an understanding of what this important process involves.

The Importance of Using Only the Right Amount of Torque

Ring nuts hold the vehicle's wheels on the axle and are thus extremely important to the driver's safety. Amateur mechanics sometimes make the mistake of thinking it's best to apply as much torque as possible when installing them. The reason is that this tightening of the lug nuts should also ensure that the wheel stays in place. In reality, applying too much torque to a bolt will actually physically stretch it. So the bolt can now crack, shear, loosen, or even break completely, so it's far from safe. On the other hand, a lug nut that is not given enough torque will not be able to stay in place once the vehicle starts moving, because the applied force will quickly push it off the bolt.

Torque specifications are different for each car

Each vehicle requires a different amount of torque when installing wheels. Specifications must be specified in the vehicle owner's manual. They are also available in industry reference guides, or you can simply find them by going through ProDemand.

Installing the clamp nuts

Once you understand what torque to use, you can install the clamp nut. To do this, you will need the following tools:

- brake rod

- impact wrench

- Wrench

First, you will need a nut, which is required in the owner's manual for that particular car.

You will then need a torque rod that fits with it. Slide a union nut around the bolt and place the torque rod over the head of the bolt.

Then, on the other end of the torque rod, use an impact wrench to turn the jam nut into place.

Finally, set the torque wrench to the value given in the manual and check your work to make sure the installation was successful.

Installing nuts in the correct sequence

It is very important that you know how to follow the correct sequence during installation. Clockwise installation is another mistake often made by hobbyists. It's not what they teach in driving schools.

Instead, you will actually be following a cross sequence. If you have a wheel with five bolts, imagine that each has a number starting with one at the top and ending with five immediately to its left. In this case, you should tighten in the following sequence:

- one

- 4

- two

- Five

- Three

If you have six bolts, where "one" is at the top right and "six" is at the top left, the sequence would look like this:

- one

- 4

- Шесть

- Three

- Five

- two

Installing the clamp nuts in this manner is the only safe method. A clockwise approach will cause the wheel to sit unevenly on the axle, which is dangerous and could result in a serious accident.

As you can see, installing the clamp nuts is not an overly technical procedure. All it takes is the right tools and doing one of the above sequences, but it has to be done right or your customers' lives will be in danger.

If you are a certified technician and interested in working with AvtoTachki, apply online today to become a mobile mechanic.