Continuous "swindle": why the air suspension of a car fails ahead of time

Content

Air suspension can be found, with rare exceptions, in expensive premium cars. But the advanced design of such a suspension is distinguished not only by the comfort of use, high price, but also by the fact that it can fail ahead of time. The AvtoVzglyad portal has figured out the main causes of premature pneuma breakdowns.

It cannot be denied that the air suspension is an extremely convenient thing that allows you to adjust the clearance depending on the road surface. Moreover, in some advanced cars, the system can do this both automatically and in manual mode. True, repairing pneumatics costs a pretty penny, and it breaks down more often than springs.

There are four major weaknesses in the air suspension system. True, here it is worth mentioning that with proper operation and proper care, the "pneuma" will live long enough. Although there are times when a fancy suspension breaks down for reasons beyond the control of the owner - simply because of the design features of the car.

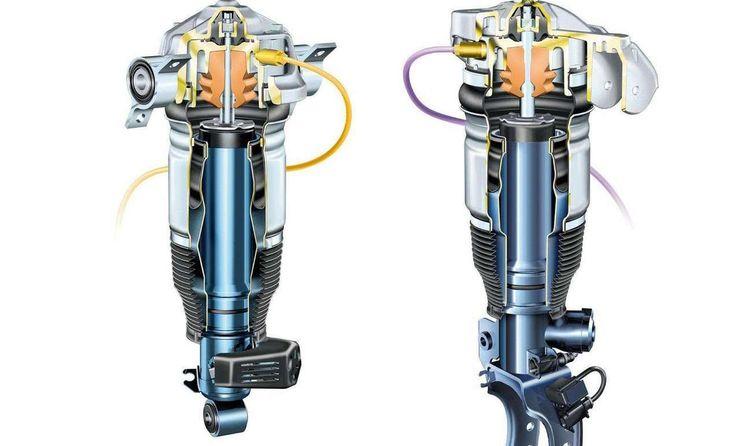

Failure of the air spring

Dirt gets into the pneumocylinders after "driving" on the real off-road, in spite of the anthers. As a result, the walls of the cylinder wear out ahead of time and can leak out. Ice can easily break through worn-out cylinders. How does he get there?

Easier than ever: water that has seeped into the system during washing in winter, or that has got here from puddles during transition temperatures, freezes.

To avoid such damage, or at least reduce the possibility of their occurrence, after driving through a slurry of water and mud, you should enter the Autobahn or walk on the suspension elements from a pressure washer yourself. If the car was washed in winter, then it is better to ask to blow the cylinders with air under pressure. And at zero, try not to leave the suspension in extreme positions.

Compressor breakdown

The main reason for compressor breakdown is untimely replacement of its filter, which does not coincide with the manufacturer's recommendations. The filter becomes clogged and ceases to fully purify the air entering the system. Because of this, dirt and sand gets into the compressor itself, acting as an abrasive. It wears out the piston group. This, in turn, leads to an increase in the load on the device, which eventually fails. Here the solution is simple: change the filter on time.

The problem with highways

The tubes of the pneumatic device are actively worn out due to the aggressive external environment. To put it simply, because of the reagents poured and poured into the snow-covered Russian streets in kilotons. It is the chemical solutions designed to relieve motorists of icy conditions that reduce the service life of some automotive components - including accelerating the breakdown of the "pneuma".

In order to avoid the aforementioned problems, it would be worth replacing the caustic reagent in the fight against ice on asphalt with something more humane. But here the drivers do not decide anything. Therefore, it is better to wash your car more often. And to blow through the cylinders, of course.

"Glitches" in electronics

Most often, problems with electronics, affecting the operation of the air suspension, occur in older SUVs of one well-known British brand. For example, when one small wire rots away, supplying power to the brake pedal position sensor.

Due to this defect, the suspension system goes into emergency mode, and the car "falls on the belly." There is no way to prevent the problem. It lies solely in the design features of the car.