Starter does not work

Content

When operating cars, regardless of the type of engine installed, a common malfunction is the failure of the starter, as a result of which it is impossible to start the engine after the ignition is turned on. In other words, the car's starter does not respond when the key is turned in the ignition. In such situations, after turning the key, instead of turning the crankshaft of the internal combustion engine, the starter is completely silent, buzzes or clicks, but does not start the engine. Next, we will consider the main malfunctions, when the starter does not react in any way to turning the key in the ignition, as well as other reasons that can lead to failure of the starter.

Why does the starter not work

An automotive starter motor is a battery-powered electric motor designed to start a gasoline or diesel engine. Therefore, this device is characterized by both mechanical failures and problems in the power supply circuits or problems in the contact zone. If the car starter does not respond to turning the key in the ignition and does not make sounds (with certain problems, the starter clicks or buzzes), then the test should begin with the following:

- determine the integrity of the battery charge (battery);

- diagnose the contact group of the ignition lock;

- check the traction relay (retractor)

- check the performance of the bendix and the starter itself;

The contact group of the ignition switch can be checked very quickly. To do this, just insert the key and turn on the ignition. The lighting of the indicators on the dashboard will clearly indicate that the ignition unit is in working condition, that is, the fault in the ignition switch should be repaired only if the indicated indicators on the dashboard go out after turning the key.

If you suspect a battery, it will be enough to turn on the dimensions or headlights, and then evaluate the illumination of the bulbs on the dashboard, etc. If the indicated electricity consumers burn very dimly or do not burn at all, then there is a high probability of deep battery discharge. You should also check the battery terminals and ground to the body or engine. Insufficient or missing contact on the ground terminals or wire will result in severe current leakage. In other words, the starter will not have enough power from the battery to start the engine.

Particular attention should be paid to the "negative" cable that comes from the battery and connects to the car body. A common problem is that contact with the ground may not disappear all the time, but with a certain frequency. To eliminate it, it is recommended to disconnect the mass at the point of attachment to the body, clean the contact well and then try to start the engine again.

To check the car battery with your own hands, you need to remove the negative terminal, after which the voltage at the battery outputs is measured with a multimeter. A value below 9V will indicate that the battery is low and needs to be recharged.

Characteristic clicks when trying to start the engine, also accompanied by a noticeable decrease in brightness or complete extinction of the lights on the dashboard, indicate that the solenoid relay is clicking. The specified relay can click both in the event of a discharge of the battery, and as a result of a malfunction of the retractor or starter.

Other reasons why the starter may not respond when the ignition is turned on

In some cases, there are malfunctions of the car's anti-theft systems (car alarm, immobilizer). Such systems simply block the supply of electrical current to the starter after disassembly. At the same time, the diagnostics show the full operability of the battery, power contacts and other elements of electrical equipment involved in starting the engine from the starter. For an accurate determination, it is necessary to supply power directly from the battery to the starter, that is, bypassing other systems. If the starter works, there is a high probability that the car's anti-theft system or immobilizer will fail.

The next item to check is the electromagnetic relay. In the event of a breakdown, the starter may:

- be completely silent, that is, do not make any sounds after turning the key to the "start" position;

- hum and scroll, but do not start the engine;

- press several times or once without moving the crankshaft;

Bendix and the retractor

The above symptoms will indicate that the malfunction is localized in the retractor relay or the bendix does not engage the flywheel. Note that in the case of the Bendix, a more characteristic sign is that the starter creaks and does not start the engine. Also a common symptom of a bad starter is that the starter hums but won't start the engine.

To test the traction relay, apply battery voltage to the relay power terminal. If the motor starts to spin, then the retractor starter is clearly defective. Frequent breakdown - nickel burnout from contacts. To remove it, you will need to remove the relay to remove the nickels. After disassembly, you still need to be ready for the prompt replacement of the traction relay, since at the factory the contact pads are covered with special protection that prevents fire during operation. Peeling will mean that said layer has been removed, so it is difficult to predict when to re-burn retractor pennies.

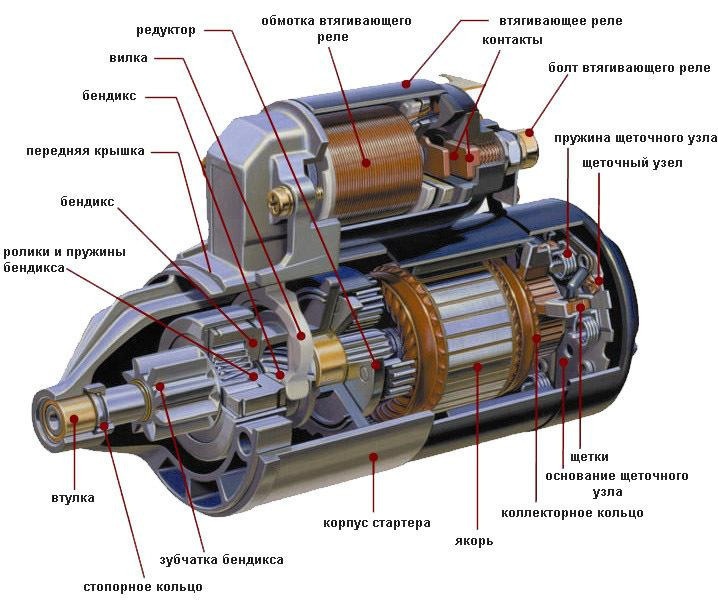

Now let's pay attention to the trunk bendix. Bendix is a gear through which torque is transmitted from the starter to the flywheel. The Bendix is mounted on the same shaft as the starter rotor. For a better understanding, it is necessary to understand how the starter works. The principle of operation is that after turning the ignition key to the “start” position, current is supplied to the electromagnetic relay. The retractor transmits voltage to the starter winding, as a result of which the bendix (gear) engages with the flywheel ring gear (flywheel ring). In other words, there is a combination of two gears to transfer starting torque to the flywheel.

After starting the engine (the crankshaft starts to rotate independently), when the starter is running, the key in the ignition lock is thrown out, the electric current to the traction relay stops flowing. The absence of voltage leads to the fact that the retractor disengages the bendix from the flywheel, as a result of which the starter stops spinning.

The wear of the bendix gear means the lack of a normal connection with the flywheel ring gear. For this reason, a creaking sound can be heard when the engine is cranking, and the starter can also rotate freely without engagement and hum. A similar situation occurs when the teeth of the flywheel ring gear are worn. Repairs include disassembling the starter to replace the bendix and/or removing the transmission to replace the flywheel. To check the bendix yourself, you will need to close two power contacts on the traction relay. The electrical current will bypass the relay, which will determine the rotation of the starter. In the event that the starter turns easily and buzzes, you should check the quality of the engagement of the bendix with the flywheel.

Starter bushings

A frequent breakdown also includes a malfunction of the starting bushings. Starter bushings (starter bearings) are located at the front and rear of the machine. These bearings are required to rotate the starter shaft. As a result of wear of the starter shaft bearings, the traction relay clicks, but the starter does not turn on on its own and does not crank the engine. This error looks like this:

- the starter shaft does not occupy the correct position along the shaft;

- there is also a short circuit of the primary and secondary windings;

A similar situation can lead to the fact that the windings burn out, the power wires melt. Sometimes a short circuit occurs in the electrical circuits of the car, causing a fire. In the event that the starter clicks, but does not turn on on its own, you cannot hold the key in the “start” position for a long time. A few short start attempts are recommended, as there is a possibility that the shaft may return to its place.

Please note that even after a successful start of the internal combustion engine, the starter will require immediate and mandatory repair to replace the bearings. Be aware that adjusting the starter shaft can cause a short circuit and fire. We also add that a starter with problematic bushings can work absolutely “cold”, but refuse to spin “hot”.

If the starter does not heat up or the engine does not spin well after warming up, then it is necessary:

- check the battery, battery terminals and power contacts. If the battery is in good condition and was 100% charged before the trip, and then discharged, then you need to check the generator regulator relay, generator belt, tension roller and the generator itself. This will eliminate the discharge of the battery and the subsequent undercharging in motion;

- then you need to pay attention to the ignition system and the fuel supply system, check the spark plugs. The lack of feedback on the operation of these systems, accompanied by the fact that the starter does not turn well with a charged battery, will indicate a starter malfunction.

Please note that the device gets very hot together with the engine in the engine compartment. Heating the starter causes thermal expansion of some elements inside the device. After repairing the starter and replacing the bushings, the specified expansion of the starter bearings occurs. An error in selecting the correct bushing sizes can result in shaft lockup, resulting in the starter not turning or turning very slowly on a hot engine.

Starter brushes and windings

Since the starter is an electric motor, the electric motor works by applying voltage to the primary winding from the battery through the brushes. The brushes are made of graphite, so they wear out in a fairly short period of time.

A fairly common scheme is when, when the critical wear of the starter brushes is reached, electricity is not supplied to the solenoid relay. In this case, after turning the ignition key, the starter will not react in any way, that is, the driver will not hear the hum of the electric motor and the clicks of the starter traction relay. For repair, you will need to disassemble the starter, after which it is necessary to inspect the brushes, which may wear out and require replacement.

In the design of an automobile starter, windings are also subject to wear. A characteristic sign is the smell of burning when starting the engine, which will indicate an impending starter failure. As in the case of brushes, the starter must be disassembled, and then assess the condition of the windings. Burnt windings darken, the varnish layer on them burns out. We add that usually the starting winding burns out from overheating if the engine runs for a long time, when it becomes difficult to start the internal combustion engine.

Summing up, I would like to note that the starter can be turned for no more than 5-10 seconds, after which a break of 1-3 minutes is required. Ignoring this rule leads to the fact that inexperienced drivers manage to land the battery and quickly burn out a fully functional starter if the engine does not start for a long time. In such a situation, it is often necessary to change the starter, since rewinding burnt starter windings is not much cheaper than buying a new starter.