Compression ratio of a diesel engine - how to increase the parameters?

Content

Do you know how the heart of your car, the engine, works? What processes occur when you press on the gas pedal or when you switch gears? Do not deny this knowledge - the better you know your car, the sooner you will feel a possible malfunction. One of the important characteristics is the compression ratio of the engine.

We study the theory - what happens inside the combustion chamber?

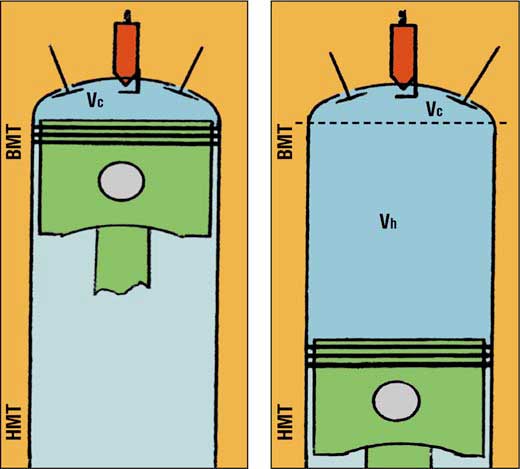

The compression ratio in theory is the ratio of the volume in the space above the working piston at the moment when it passes the bottom dead center to the volume in the chamber above the piston at the moment it passes the top dead center. This definition expresses the pressure difference in the combustion chamber itself at the moment when fuel is injected into the cylinder.

In everyday life, the compression ratio is often confused with another concept, namely the compression of a diesel engine, but in practice these are two different terms. Compression is the maximum pressure the piston has in a cylinder as it passes from bottom dead center to top dead center. This value is measured in atmospheres.

The compression ratio is measured by a mathematical ratio, for example 19:1. For diesel engines, the ratio between 18 and 22 to 1 is considered the best. With this degree of compression, the heart of the car will work most efficiently. Fuel usage is directly related to compression ratio. The more the pressure rises in the chamber and the greater the compression, the more economical the fuel consumption will be, while the power received can increase.

Compression ratio in practice - how does it work?

Combustion of the fuel mixture in the engine occurs by the interaction of mixed vapors of fuel and air. When the mixture ignites, it expands, resulting in an increase in pressure in the chamber. At the same time, the crankshaft performs revolutions, respectively, the engine performs one cycle of useful work. Nowadays, diesel engines with a low compression ratio are practically no longer produced, since this is not necessary, and low-octane fuel has also practically disappeared from the market. Everyone is striving for more economical and high-revving engines with a higher compression ratio.

An increase in the compression ratio can be achieved by reducing the combustion chamber of a diesel engine. But with such changes, engineers in factories have to find a compromise solution, because they need to maintain pressure in the chamber, as well as reduce the amount of fuel burned. One way to increase compression is to bore the cylinder head blocks - the compression ratio increases, and the volume of fuel combustion in the chamber decreases. In this case, the cylinder retains its working volume, and the engine displacement does not change.

Watch this video on YouTube

Changing the compression ratio - how to improve performance?

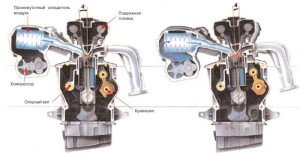

Nowadays, engineers have found an alternative way to increase the pressure in the combustion chamber - this is the installation of a turbocharger. The installation of this device leads to an increase in pressure in the internal combustion chamber, while the volumes of the chamber itself do not need to be changed. The appearance of such devices has led to a significant increase in power, up to 50% of the original figures. The advantage of superchargers is the ability to install them yourself, although it is best to entrust this task to specialists.

The principle of operation of superchargers of all types comes down to one simple action, which is understandable even to children. We know that a car engine works due to the constant combustion of the fuel-air mixture entering the engine cylinders. Manufacturers set the optimal ratio of fuel and air entering the cylinders - the latter enters the combustion chamber due to the creation of a rarefied atmosphere at the intake stroke. Superchargers, on the other hand, allow more fuel and air to be supplied at the inlet to the same volume of the combustion chamber. Accordingly, the amount of energy during combustion increases, the power of the unit increases.

However, motorists should not get carried away by an excessive increase in the initial indicators of their “iron horse” - with an increase in the amount of thermal energy, the depreciation of engine parts also increases.

Pistons burn out faster, valves wear out, the cooling system fails. Moreover, if turbocharging can be installed with your own hands, then it is far from always possible to eliminate the consequences of this experiment even in a good auto repair shop. In especially unsuccessful cases of auto modernization, its “heart” can simply explode. It hardly needs to be explained that the insurance company will refuse to pay you any compensation under this precedent, placing all responsibility solely on you.

Diesel engines do not have a throttle valve, as a result of which it is possible to fill the cylinders better and more efficiently, regardless of rpm. On so many modern cars, a device such as an intercooler is installed. It allows you to increase the filling mass in the cylinders by 20%, which increases the engine power.

The increased compression ratio pressure of a diesel engine is not always positive and does not always increase its power. The operating compression ratio may already be near its knock limit for a given type of fuel, and increasing it further can reduce engine power and run time. In modern cars, the pressure in the combustion chamber is constantly controlled and controlled by electronics, which quickly respond to changes in engine performance. Before performing any operations to increase the parameters of a modern "iron horse", be sure to consult with specialists.

Watch this video on YouTube

• Common Rail system.

A modern system that is used on most modern vehicles with a diesel power plant. The principle is that the fuel mixture is always supplied to the combustion chambers with the same pressure, regardless of the engine speed and power. If in a conventional system compression occurs in the intake manifold, then in the common rail at the time of fuel injection into the chamber. Thanks to this system, productivity is increased by 30%, however this figure may vary depending on the fuel injection pressure.

• Chip tuning.

An equally popular way to increase power is chip tuning. The principle of refinement is to change the characteristics of the pressure in the fuel system by changing the parameters of the electronic engine control unit. The chip improves the performance and efficiency of the engine, and also monitors the time of fuel supply to the cylinders. In addition, chip tuning allows you to reduce fuel consumption and make operation more economical.

To perform chip tuning yourself, you will need special equipment, knowledge and experience. Installing a modified controller necessarily implies fine-tuning for a specific engine; it is also necessary to carry out diagnostics first. Therefore, to obtain a guaranteed result, it is better to turn to professionals.