Maintenance and care of sprue cutters

Content

| Like all tools, sprues can extend their life with a few simple care and maintenance steps. | |

Service after use | |

| After you've finished using a sprue cutter, you should always clean it before putting it away. To do this, you will need four things: a small brush, a polishing cloth, some multi-purpose water-repellent oil, and some tool lubricant. |

| Step 1 - BrushingFirst, use a small brush, such as an old toothbrush, to brush off any small debris that may be left on the sprue cutters. |

| Step 2 - Wipe cleanThen use a polishing cloth to wipe the jaws. This will remove very fine debris that can build up over time and dull the cutting edges. |

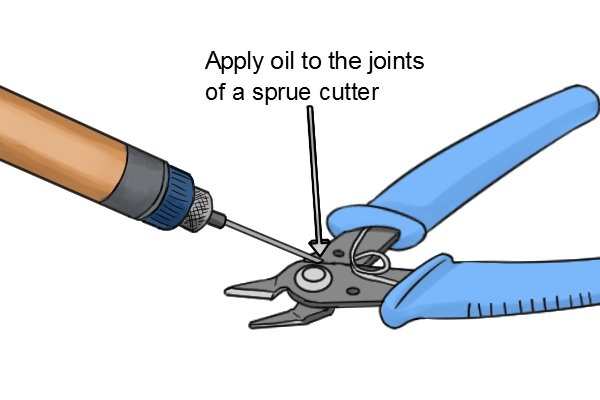

| Step 3 - OilPut a drop of multipurpose water repellent oil into all sprue joints. This will prevent the joints from being corroded by moisture and thus keep them moving freely, while also lubricating them to prevent them from stiffening. |

| Step 4 - Lubricate the cutting edgesApply burr lubricant to the cutting edges of the gate cutter. This will protect the jaw cutting edges from corrosion and will also reduce friction on the cutting edges the next time you use the sprue. This, in turn, simplifies the use of the torch and prolongs the life of the cutting edges. |

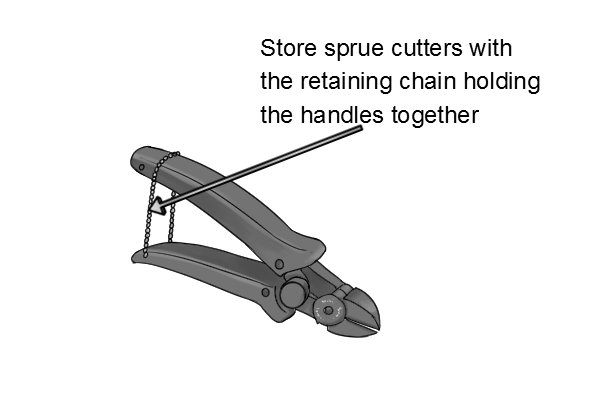

| Step 5 - Keep AwayIf your sprue has a lock chain or handle lock, you should store it with it. Cast cutters should be stored in a toolbox or workbench drawer in a moderate temperature, low humidity environment to prevent corrosion. |

Is it possible to sharpen blunt cutting edges on a sprue cutter? | |

| If the cutting edges of your gate cutter become dull over time, they can be sharpened in the following way: | |

| Tools you will need:

|

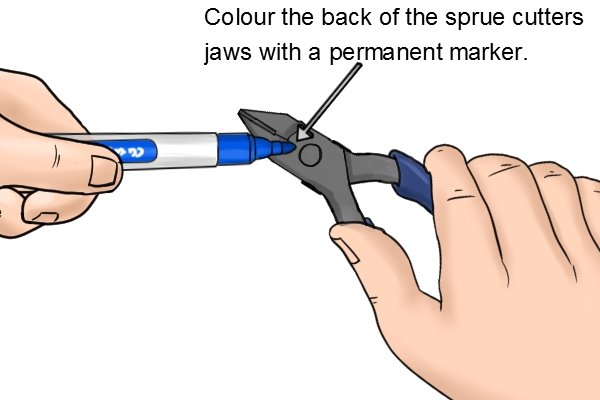

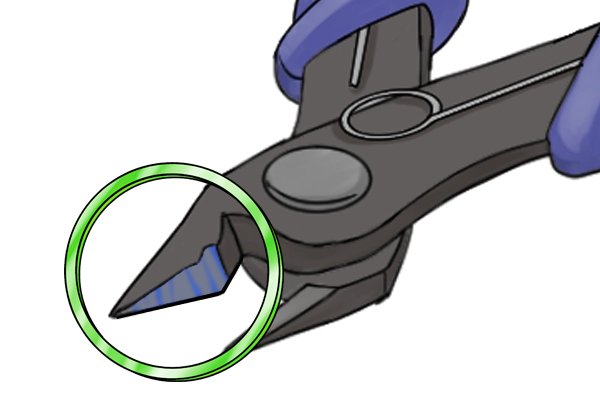

| Step 1 - Painting the back of the sprueUse a marker to color the flat back of the sprue jaws. Leave it on for a few minutes so the ink can dry. |

| If the back of your cutter's jaws is beveled, such as a micro-beveled sprue cutter, you only need to paint over the beveled part with a marker. |

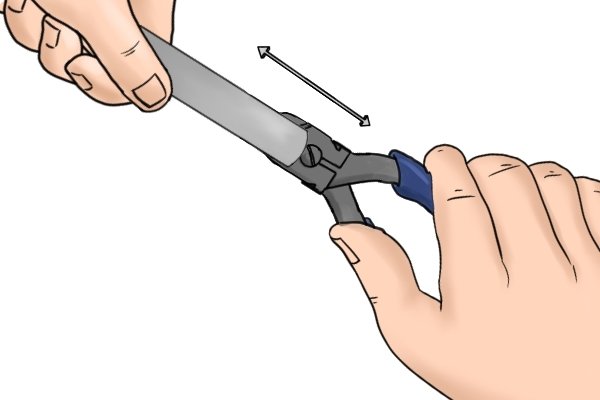

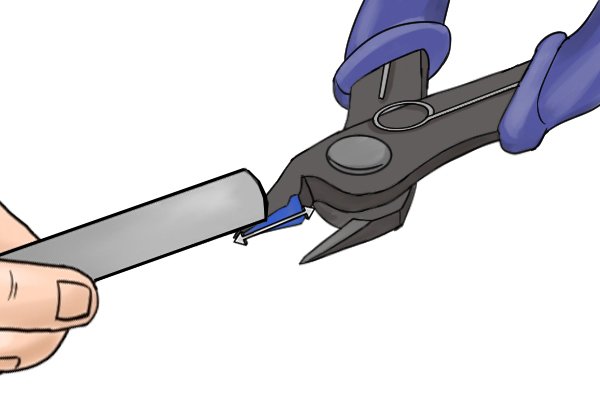

| Step 2 - File the jawsUsing a soft 400-600 grit sanding pad, sand the back of the sprue cutter jaws in a back and forth motion along the length of the jaws, not across them. |

| Make sure you evenly remove the marker from the back of the sprue jaws. This will help maintain both the cutting angle of the cutting edges and the flat back of the jaws, resulting in a better finish when cutting. |

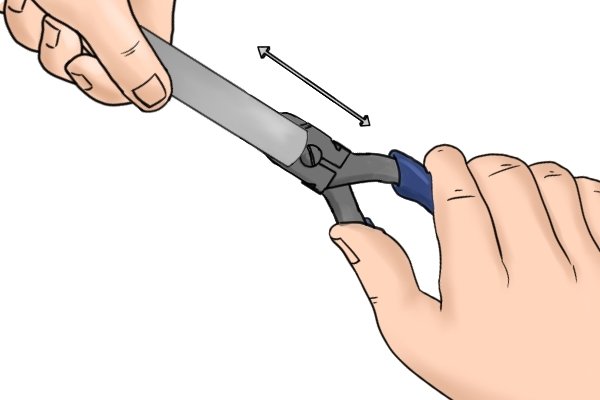

| Hold the sanding pad exactly against the bevel of the sponge and sand in a reciprocating motion from the front to the back of the sponges. When sharpening from the front to the back of the jaws and checking that the marker is removed evenly, you should maintain the original bevel angle on the jaws. |

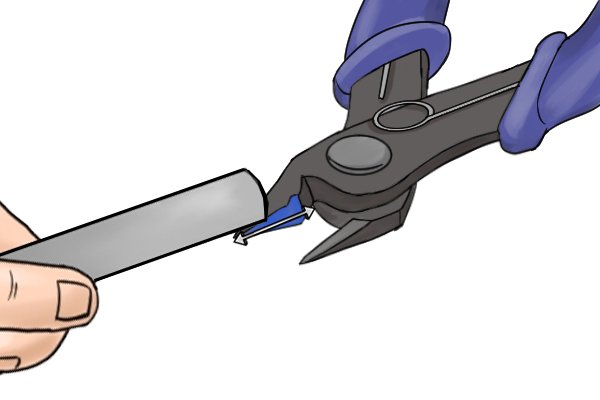

| Step 3 - Repeat on the inside of the jaws.Use a marker to color the inside of the sprue jaws. Leave it on for a few minutes so the ink can dry. |

| Step 4 - Sharpen the inside of the jawsUsing a soft 400-600 grit sanding pad, sand the inside of the sprue jaws one side at a time, back and forth along the full length of the sprues without crossing them. |

| Make sure you remove the marker from the jaws evenly, keep the sanding pad flat on the inside of each jaw to maintain the bevel angle. |

How to replace a broken sprue spring | |

| Not all gate cutter springs are replaceable: this is only the case for some of the smaller gate cutters with a single helical spring. |

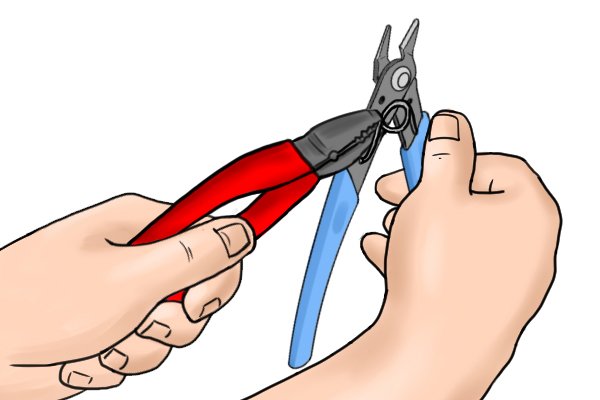

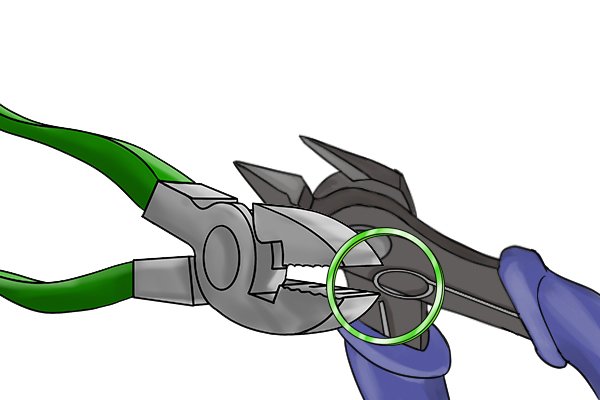

| Step 1 - Remove the old springBefore installing a new spring, you must first remove the old one. If the arms of a single coil spring are just past the pivot point of the clamps, turn the spring to disengage the arms from the holes in which they are located. You may find it easier to do this with pliers. |

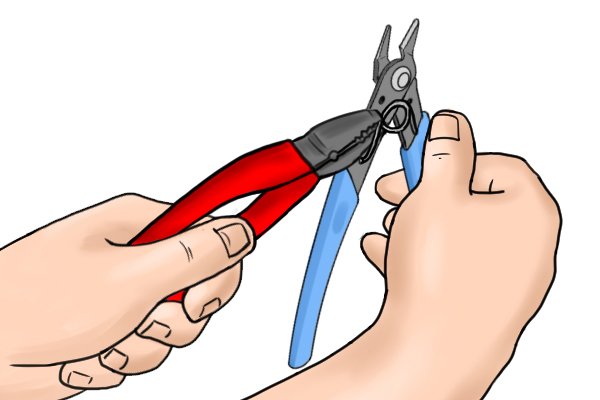

| If the arms of a single coil spring are half attached to the handles, you must first remove the handle bushings. To do this, simply slide the handle sleeves off the handles. This will expose the spring arms and allow the spring to be unscrewed from the holes they are in. Again, this may be easier to do with pliers. |

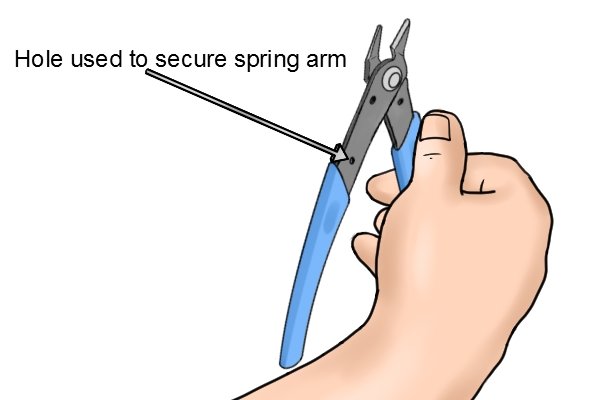

| Step 2 - Find the first handOnce the old spring has been removed, place the first arm of the new spring into one of the holes that are used to attach them. |

| Step 3 - Find a second handOnce you have located the first arm of the spring, squeeze the two arms of the spring together until the second arm meets the hole that is used to hold it in place. Screw the second arm of the spring into the hole that fixes it. Again, this can be easier with the help of pliers. |

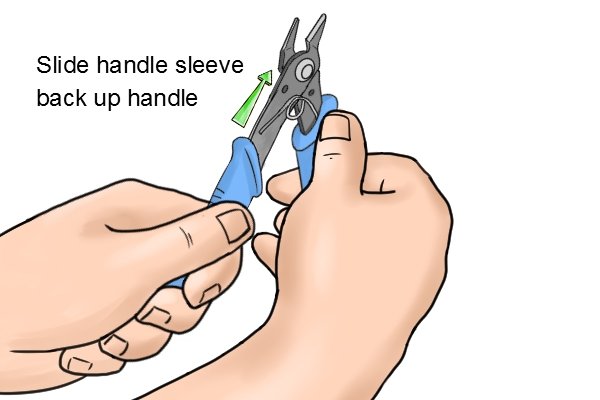

| If the spring arms are halfway down the handles, then you must now slide the handle sleeves back up the handles over the spring arms to lock them in place. |

How long do sprue cutters last? | |

| This question cannot be answered, as the life of a sprue cutter will depend on how often it is used, the thickness and hardness of the material it is used on, what maintenance is done, and where and how it is stored. However, with proper use and care, gate cutters will last for many years. |

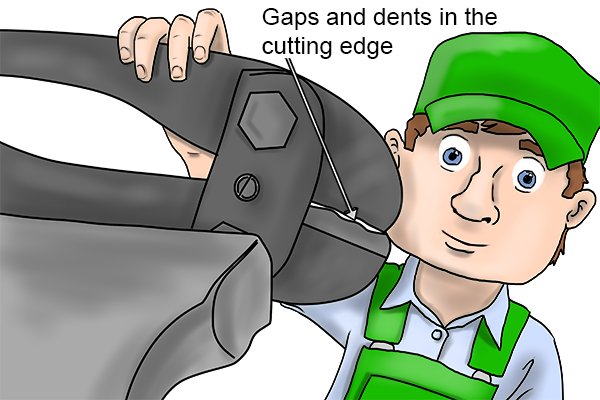

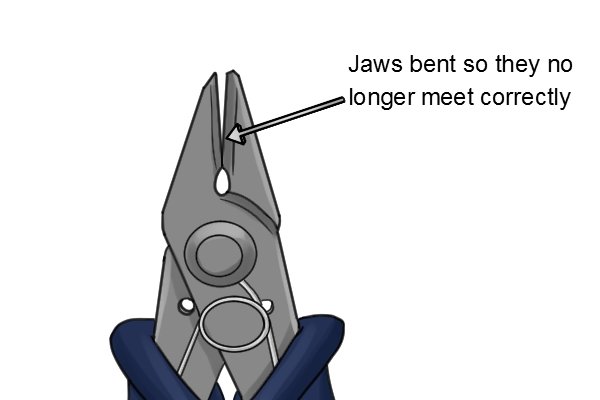

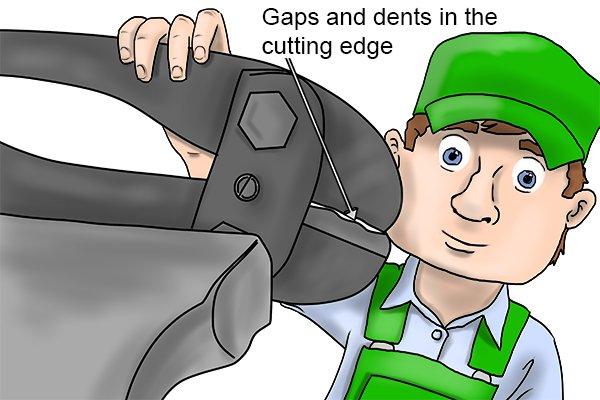

| Reasons to replace the gate cutterIf you use a single lever sprue cutter with thin jaws on material that is too thick or hard, this can result in large dents or burrs on the sprue cutter's cutting edges, or even warping of the sprues themselves. In this case, it is unlikely that you will be able to repair the cutting edges so that they cut correctly, in which case the sprue cutter should be replaced with a new one. |

| The cutting edges of even large compound sprue cutters can be dented and damaged due to cutting sprues that are too thick or too hard. |

| As a general rule, you should consider replacing a sprue cutter if its jaws have been damaged so that it no longer cuts the sprue well, it has become too stiff and tedious to work with, or if the handles are damaged making it uncomfortable. use. |