Replacement technology and repair possibilities for road vehicle glass

Vehicle glazing provides the function of light penetration into the vehicle cabin, allows the crew to control the situation on the road and its surroundings, the ability to view the vehicle, and also serves to protect passengers (cargo) from adverse weather conditions. (wind, UV radiation, heat, cold, etc.). Proper glass installation also strengthens the body. Replacement or repair of glasses is carried out mainly when they are scratched (for example, by windshield wipers), when a bearing cracks or leaks. The glazing conditions of vehicles are regulated by the Decree of the Ministry of Transport and Communications of the Slovak Republic SR 464/2009 - Detailed information on the operation of vehicles in road traffic. § 4 para. 5. Modifications and repairs to the glazing of vehicles leading to a reduction in light transmission may only be carried out under the conditions laid down in UNECE Regulation No. 43. Modifications and repairs to the glazing of a vehicle may only be carried out outside the control zone "A" of the windshield. The technology for processing and repairing glazed surfaces of vehicles should ensure that the glass does not change the color of objects, signal lights and light signals in the repaired area.

Some theory

All car windows are divided into front, side and rear. Sides to the right or left, back or front, pull-out or triangular. In this case, the rear and front windows are heated and not heated. Windshields and rear windows can be divided into rubber or body-glued and all windows by color. Glass mounted on rubber in passenger cars is mainly used on older types of vehicles. In new types, there is practically no such assembly, with the exception of cars made according to the special wishes of buyers. It is slightly more common in commercial vehicles (trucks, buses, construction equipment, etc.). In general, it can be said that this technology has already been largely supplanted by the technology of glass glued to the body.

Laminated glass is attached to the body with special clips. These are two-component polyurethane-based fixtures with a curing time of 1 to 2 hours (the time after which the vehicle can be used) at 22 ° C. These products are developed in cooperation with car glass manufacturers and act as a link between the body and the ceramic frame. at a temperature of about 600 ° C directly on the surface of the car glass. If the technological procedure is followed, the fixation is almost constant.

Windshields and their equipment

In general, windshield equipment can be roughly divided into the following categories: tinting, heating, sensors, antennas, acoustic film, rear projection onto the windshield.

Automotive glass painting

It is a technology that reduces light transmission, suppresses light energy, reflects light energy, attenuates UV radiation, absorbs light and thermal energy from solar radiation, and increases the shading coefficient.

Construction and painting (tinting) of automobile glass

Explaining the types of windshield tinting without knowing their design may be incomprehensible, so I will give the following information. The windshield consists of two layers of tinted or clear glass and a protective film between these layers. The color of the glass is always determined by the color of the glass, the color of the sun protection strip is always determined by the color of the foil. The glass shape is cut from flat sheet glass and placed in a glass furnace in a special shape that mimics the future shape of automotive glass. Subsequently, the glass heats up to a temperature of about 600 ° C, which begins to soften and copy the shape of the mold under its own weight. Immediately before heating begins, a ceramic frame is applied to one outer layer for proper bonding with the adhesive when gluing the glass to the car body in the future. The whole process takes a few seconds. In this way, both layers of glass are formed, and then an opaque protective film is inserted between them. The entire product is placed back in the oven and heated to 120 ° C. At this temperature, the foil becomes transparent and air bubbles are expelled capillary. In this case, the film copies the shape of both glass layers and forms a continuous homogeneous element. At the second stage, metal mounts for mirrors, sensor mounts, antenna terminals, etc. are attached to the inner layer of car glass using the same technology. In case of heating, the heated glass is inserted between the foil and the outer layer of the car glass, the antenna is inserted between the foil and the inner layer of the car glass.

In general, it can be stated that the windows are painted to increase the comfort of the vehicle user, reduce the temperature in the vehicle and protect the driver's eyes, while maintaining the view from the vehicle even under artificial lighting. The color of car glass is usually green, blue and bronze.

A special category includes glasses with Sungate technology, which contain a special self-darkening layer on the glass that responds to the intensity of solar energy. When looking at these glasses, a purple tint is clearly visible.

Often there are windshields with the so-called. sunbathing. It is an element that again reduces the temperature in the car and protects the driver's eyes. The sun's stripes are usually blue or green. However, there is also a gray color. This stripe has the same protective properties as the blue and green stripes, but unlike them, it is practically invisible from the front seats of the vehicle and, therefore, does not reduce the view from the vehicle.

Sensors on car windows

These are, for example, o rain and light sensors, etc., which are responsible for wiping the water curtain on the windshield, turning on the headlights in poor visibility conditions, etc. The sensors are located in the immediate vicinity of the interior rearview mirror or directly below it. They are connected to the glass using an adhesive gel strip or are directly part of the windshield.

Car side windows

The side and rear windows are also tempered, and this is practically the same technology as in the case of windshields, with the difference that the windows are mostly single-layer and without a protective film. Like windshields, they heat up to 600°C and shape them into the desired shape. The subsequent cooling process also causes excessive stress (stretching, impact, heat, etc.) to break the glass into small pieces. Side windows are divided into right and left, rear or front and retractable or triangular. Rear triangular windows can be located in the door or fixed in the car body. The rear side windows can be painted in a shade called Sunset or Sunsave glass. Sunset Technology is a treatment that is able to eliminate solar energy by up to 45% and attenuate UV radiation by up to 99%. Sunsave glass technology is glass that is produced using the same technology as double-layer windshields with a protective film between the two layers of glass. The color of the window is decided by coloring one or both layers of glass, while the foil remains transparent.

Rear car windows

The manufacturing technology is exactly the same as for the side windows, including the Sunset and Sunsave glass technologies. The more significant difference lies only in the heating of the glass and some specific elements such as opaque ceramic brake light frames, including metal fasteners, wiper and washer openings or connections for heating and antennas.

Glass replacement technology

Most often, damaged windshields are replaced; currently, double-glazed windows are most often glued in passenger cars. For vehicles with an earlier production date or for trucks, buses and side windows, the glass is usually surrounded by a rubber frame.

Laminated glass replacement procedure

- Preparation of all working equipment, necessary accessories. (picture below).

- Remove trim strips, seals, brackets and wipers according to the vehicle manufacturer's instructions. Before removing the old glass, the body surfaces should be protected with masking tape so as not to damage the paintwork.

- Damaged glass can be cut with the following tools: electric pick-up, separating wire, thermal knife (care must be taken to properly regulate the temperature of the knife, otherwise the cutting surface of the old glue may be charred). We always use safety glasses when replacing car windows.

- The very course of cutting glass.

- Cut off the remaining adhesive on the flange of the car body to approximately thickness. Layer 1-2 mm thick, which creates an optimal new surface for applying new adhesive.

- Installation and inspection of new glass. To obtain the best possible storage accuracy, we recommend that you measure new glass before activating it. Insert all spacers and mark the correct position of the glass with masking tape.

- Pre-treatment of car glass: cleaning the glass with a product (Activator). Wipe the bonded glass surface with a clean, lint-free cloth or paper towel dampened with product. Apply in a thin layer in one stroke, then wipe off. Ventilation time: 10 minutes (23 ° C / 50% RH). Caution: UV protection: when replacing car windows without a black ceramic cover or screen coating, after activating the glass with a preparation, apply a so-called primer with a thin cover layer using a brush, felt or applicator. Ventilation time: 10 min (23 ° C / 50% RH).

Flange surface pretreatment

Cleaning from dirt with a product. Wipe the bonding surface with a clean cloth, respectively. paper towel dampened with product. Apply in a thin layer in one stroke, then wipe off. Ventilation time: 10 minutes (23 ° C / 50% RH).

- After the activation step, repair any paint damage caused by removing the old glass with the repair paint, which is usually part of the tool. In the event of serious damage to the paintwork, we recommend using the original repair paint specified by the vehicle manufacturer. Caution: Do not paint over old glue residue.

- The preparation of the glue cartridge itself - removing the cap, protective cover, placing the cartridge in the glue gun.

- Apply glue to the glass acc. to the edge of the case in the form of a triangular track using the special tip supplied with the product. Attention: if necessary, depending on the height of the body flange and the data of the vehicle manufacturer, it is necessary to correct the shape of the tip.

- Installation of new glass. New glass must be installed within the adhesive setting time specified in the product specifications. To facilitate the handling of glass, we use holders - suction cups. Press lightly on the adhesive line along its entire length to ensure good contact with the adhesive. When installing new glass, keep the doors and side windows open so you can work on the glass from inside the vehicle.

- Reinsert trim strips, plastics, wipers, interior rearview mirror or rain sensor. If necessary, remove residual adhesive with a product before curing.

The procedure for replacing the glued windshield is also shown in the following video:

Replacing rubber-framed glass

So-called rubber lenses or lenses inserted into a rubber seal are only used in older types of passenger cars. However, in vans and trucks, some manufacturers still use this method of securing glass. The advantage of replacing such glasses is time saving.

In older cars, corrosion occurs at the edge of the hole in which the glass is installed. Corrosion repels the sealing rubber and begins to penetrate through these places. We solve this problem by sealing the leaks with a special sealing paste. If the sealing paste does not work, it is necessary to remove the glass from the housing, have a professional plumber repair the rusted areas and reinstall the glass, if possible with a new rubber seal.

Windshield repair

Repair or assembly is an alternative to complete disassembly and replacement of automotive glass. In particular, a crack is repaired by drawing in air from the cavity of the crack and replacing it with a special substance with the same refractive index as light.

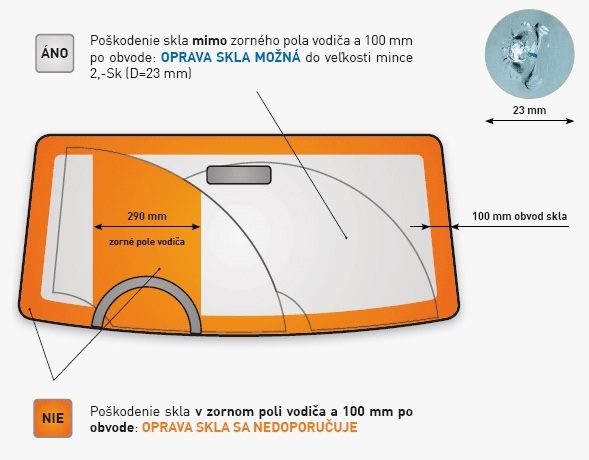

The repair will restore the original strength and stability of the automotive glass and at the same time significantly improve the optical properties at the site of the original damage. 80% of cracks caused by stone impacts are technically repaired, provided that the crack does not end at the edge of the glass.

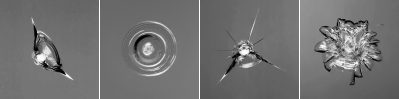

According to the shape, we distinguish certain types of cracks as follows:

Windshield repair reasons

Financial:

- without accident insurance or additional windshield insurance, replacing car glass can be very costly,

- even in the case of accident insurance, the customer usually has to pay a surcharge,

- with the original original windshield, the car has a higher selling value,

- for a crack in the driver's field of vision, a fine of tens of euros will be charged and may even be refused in the technical passport.

Technical:

- risk of leaks due to gluing new glass,

- If the original glass is cut, the case or the inside may be damaged,

- by repairing the crack, its further expansion will be prevented forever,

- restoration of the safety function - the front passenger airbag rests against the windshield when triggered.

By time:

- Many customers prefer a quick repair while you are waiting (within 1 hour) rather than a lengthy windshield replacement that requires the vehicle to stop as the glue dries out.

Insurers' opinion on glass repair

Insurance companies recognize this method. The reason is clear - the insurance company will pay much less for glass repair than for its replacement. If the crack meets the conditions of repair, then some insurance companies even require repair. If the client follows the proper procedure for reporting an insured event, the insurance company is obliged to pay for repairs even in the case of so-called out-of-contract services. The condition is an initial inspection of the damaged glass by a person authorized by the insurance company.

What types of car glass can be repaired?

Any double-layer car windshield can be vacuum repaired. It doesn't matter if the glass is clear, tinted, heated or reflective. This applies to cars, trucks and buses. However, the side and rear tempered glass cannot be repaired, which will shatter into many small fragments if broken. It is also not possible to repair the headlights or mirrors.

Can you see a crack after repair?

Yes, every car glass repair leaves certain optical marks, which depend on the type of crack. Only the best and most serious auto repair shops will show in advance on the model windshield what kind of optical footprint can be expected. However, after a quality repair, the original crack is almost invisible when viewed from the outside. The driver does not face a fine and the risk of problems with maintenance.

What is the largest crack that can be repaired?

Technically, it is practically possible to repair a crack, regardless of its size and length (usually up to 10 cm). However, the crack should not end at the edge of the glass, and the entry hole (the impact point of the stone - the crater) should not be larger than about 5 mm.

Does the age of the crack and the degree of contamination depend on this?

It doesn't matter if we have repaired a crack in a car service that uses exclusively professional technology.

What are these black spots inside the crack?

Dark staining (better seen if the crack is covered with white paper) is the result of air entering the crack cavity. When air enters between the first layer of glass and the foil, it causes an optical effect typical of black. With high-quality repair of cracks, air is 100% sucked out and replaced with a special substance with the same refractive index as glass. After a poor-quality repair, after a short time, the filling material is “dead” and leaves an unpleasant funnel. In the worst case, black optical traces will remain in the crack, indicating incomplete air extraction. In this case, the crack may even expand.

What types of services do car glass repairs today?

Daytime windshield repair is provided not only by specialized companies such as Autosklo XY, but also by many other services that do not need to replace car glass at all in their activities. High-quality repairs using professional technologies are also performed by tire shops, etc.

Glass repair using vacuum technology

When repairing glass, damage is eliminated by casting. First, air is sucked out of the damaged area, and when rinsing, small dirt and moisture are removed. The area is filled with clear resin and allowed to cure with UV light. Refurbished glass has the same visual and mechanical properties as intact glass. The quality of the repair is influenced by the time elapsed from the moment of damage to the moment of repair, as well as the nature of the damage. Therefore, it is important to contact the service as soon as possible. If other obligations prevent us from visiting the service, it is necessary to seal the damaged area with translucent tape. We will slow down the penetration of dirt and air humidity into the place of damage.

When repairing car windows, we must take into account, first of all, the technical aspect of the possibility of repair and the assessment of the repair performed, also from an economic and time point of view.