Fuse types

Typically, fuses are components that protect electrical devices from power surges and short circuits. However, the fuse used to protect a high power transformer cannot be used for a low power device such as a laptop.

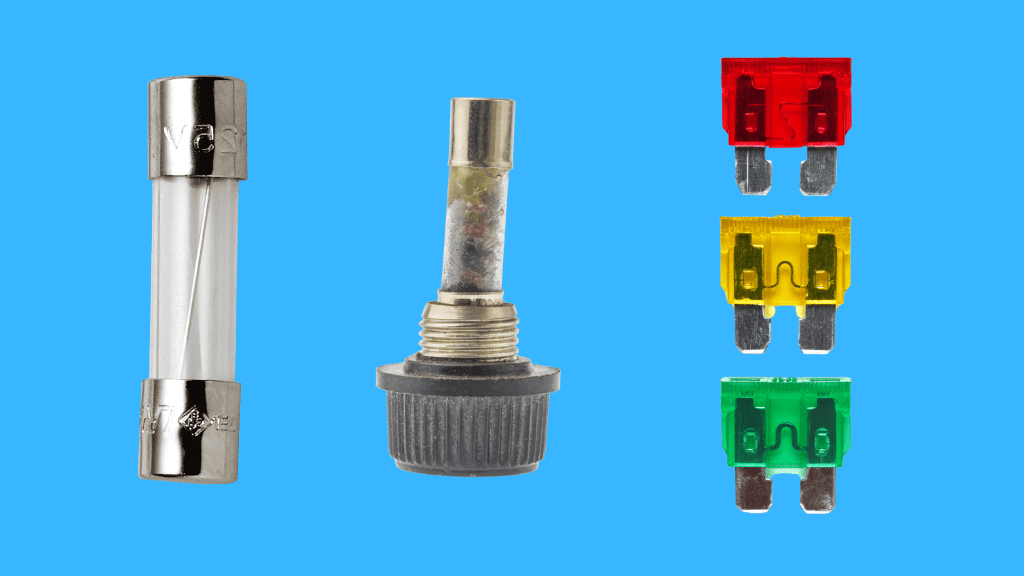

Electrical fuses come in many shapes and sizes, operate using different elements, and have different applications in their circuits.

In our guide, we present all types of fuses used in electrical systems, dividing them by main categories into subcategories and more specific options.

Let's get started.

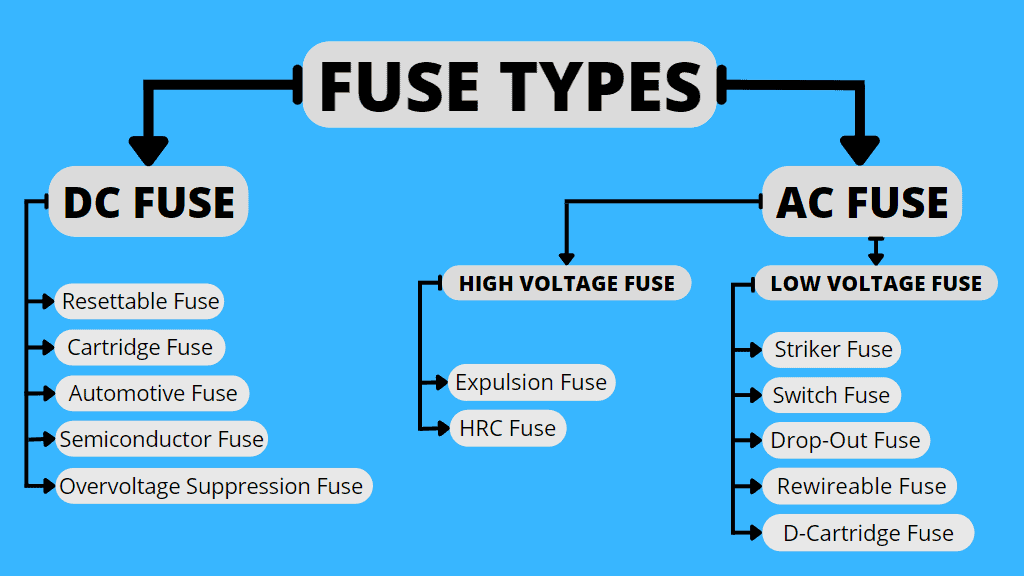

Fuse types

There are more than 15 types of electrical fuses, differing in the principles of operation, design and application. These include:

- DC fuse

- AC fuse

- Low voltage electrical fuse

- Electrical high voltage fuse

- cartridge fuse

- D-Type Cartridge Fuse

- Cartridge type fuse

- Replaceable fuse

- Striker fuse

- Switch fuse

- Push-out fuse

- Drop-down fuse

- Thermal fuse

- Resettable fuse

- semiconductor fuse

- Voltage suppression fuse

- Surface Mount Device Fuse

All this will be individually explained in detail for your full understanding.

DC fuse

Simply put, DC fuses are a type of electrical fuse used in DC circuits. While this is the main factor that differentiates them from alternating current (AC) fuses, there is another feature worth mentioning.

DC fuses are usually larger than AC fuses to avoid sustained arcing.

If the DC fuse is over-current or short-circuited and the metal strip melts, the circuit will open.

However, due to the DC current and voltage in the circuit from the DC source, the small gap between both ends of the fused strip creates the possibility of a permanent spark.

This defeats the purpose of the fuse as power is still flowing through the circuit. To prevent sparking, the DC fuse is enlarged, which increases the distance between the two melted ends of the strip.

AC fuse

On the other hand, AC fuses are electrical fuses that work with AC circuits. They do not need to be done anymore thanks to the variable frequency power supply.

Alternating current is applied at a voltage that changes from the maximum level to the minimum level (0 V), typically 50 to 60 times per minute. This means that when the strip melts, the arc is easily extinguished when this voltage is reduced to zero.

The electrical fuse should not be larger, as the alternating current stops supplying itself.

Now, AC fuses and DC fuses are the two main categories of electrical fuses. We then separate them into two subcategories; low voltage electrical fuses and high voltage electrical fuses.

Low voltage electrical fuse

This type of electrical fuse operates on a circuit with a rated voltage less than or equal to 1,500 V. These electrical fuses are commonly used in low voltage electrical circuits and come in a variety of shapes, designs and sizes.

They are also less expensive than their high voltage counterparts and are easy to replace.

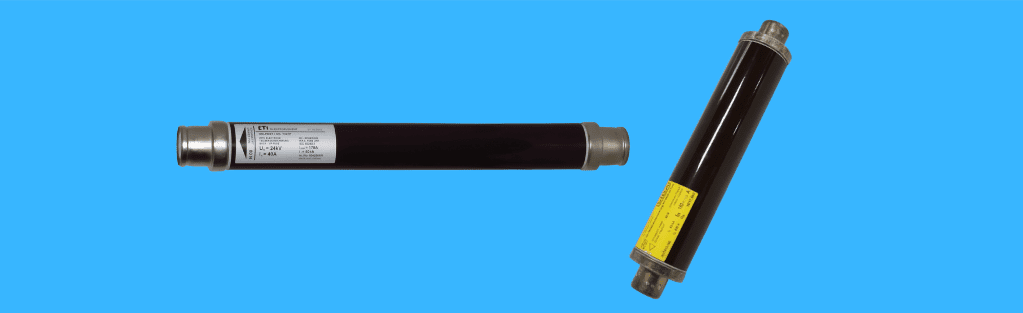

Electrical high voltage fuse

High voltage fuses are electrical fuses used with voltage ratings above 1,500V and up to 115,000V.

They are used in large power systems and circuits, come in different sizes and use more stringent measures to extinguish an electric arc, especially when it comes to a DC circuit.

Then, high and low voltage electrical fuses are divided into different types, mainly determined by their design.

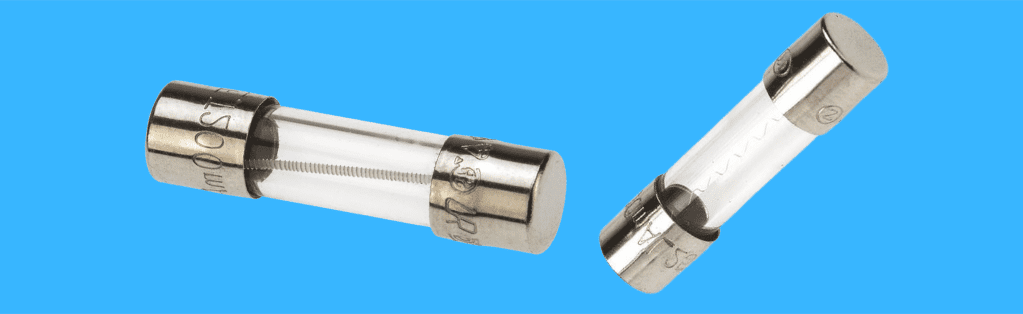

cartridge fuse

Cartridge fuses are a type of electrical fuse in which the strip and arc quenching elements are completely enclosed in a ceramic or clear glass case.

They are usually cylindrical electrical fuses with metal caps (called lugs) or metal blades at both ends that serve as contact points for connection to the circuit. A fuse or strip on the inside connects to these two ends of the cartridge fuse to complete the circuit.

You see cartridge fuses with applications in appliance circuits such as refrigerators, water pumps and air conditioners, among others.

While they are more present in low voltage power systems rated up to 600A and 600V, you may also see their use in high voltage environments. Despite this and the addition of certain materials to limit sparking, their overall design remains the same.

Cartridge fuses can be divided into two additional categories; Type D electrical fuses and Link type fuses.

Type D Cartridge Fuse

D-type fuses are the main types of cartridge fuses that have a base, an adapter ring, a cartridge and a fuse cap.

The fuse base is connected to the fuse cover and a metal strip or jumper wire is connected to this fuse base to complete the circuit. Type D fuses immediately stop the power supply when the current in the circuit is exceeded.

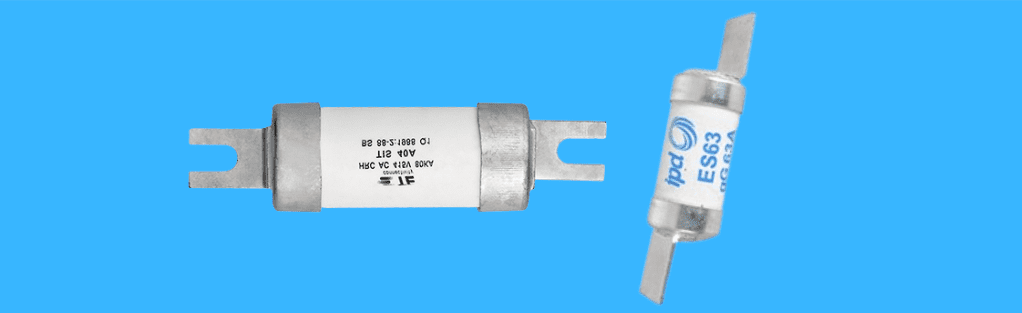

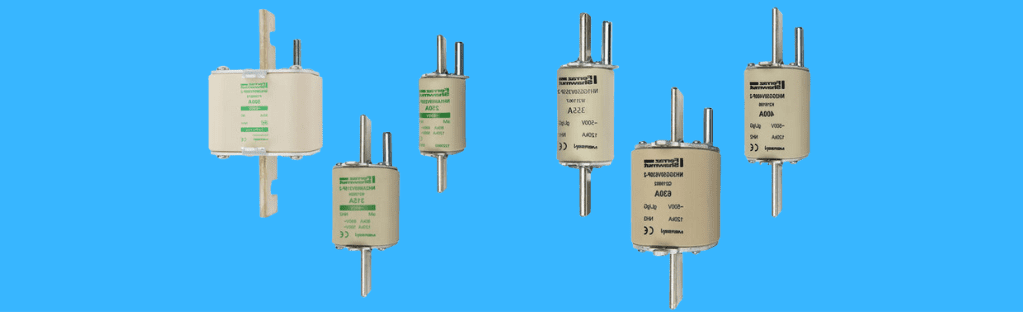

Link Type/HRC Cartridge Fuse

Link or high breaking capacity (HRC) fuses use two fuse links for a time delay mechanism in overcurrent or short circuit protection. This type of fuse is also called high breaking capacity (HBC) fuse.

Two fusible links or bars are placed parallel to each other, one with low resistance and the other with high resistance.

When excess current is applied to the circuit, the low resistance fusible link melts immediately, while the high resistance fuse holds the excess power for a short period of time. It will then burn out if the power is not reduced to an acceptable level within this short period of time.

If, instead, the rated breaking current is triggered immediately when an overcurrent occurs in the circuit, the high-resistance fuse-link will instantly melt.

These types of HRC electrical fuses also use substances such as quartz powder or non-conductive liquids to limit or extinguish the electrical arc. In this case they are called HRC liquid fuses and are common in high voltage types.

There are other types of HRC electrical fuses, such as bolt-on fuses, which have extension terminals with holes, and blade fuses, which are widely used in the automotive environment and have blade terminals instead of caps.

Blade fuses usually have a plastic case and are easily removed from the circuit in the event of a malfunction.

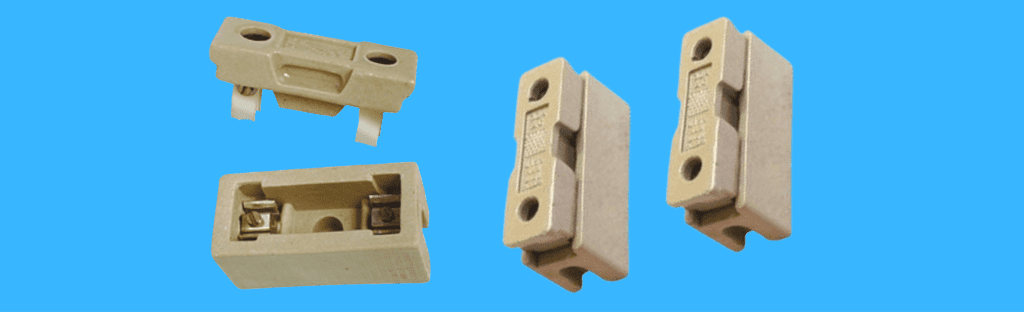

Replaceable fuse

Replaceable fuses are also called semi-closed electrical fuses. They consist of two parts made of porcelain; a fuse holder with a handle and a fuse base into which this fuse holder is inserted.

The design of detachable fuses, commonly used in residential and other low current environments, makes them easy to hold without the risk of electric shock. The fuse holder usually has blade terminals and a fuse link.

When the fusible link melts, the fuse holder can be easily opened to replace it. The entire holder can also be easily replaced without any difficulty.

Striker fuse

The fuse uses a mechanical system to protect against overcurrent or short circuits, and to indicate that an electrical fuse has blown.

This fuze works either with explosive charges or with a cocked spring and a rod that is discharged when the link is melted.

The pin and spring are parallel to the fusible link. When the link melts, the unloading mechanism is activated, causing the pin to fly out.

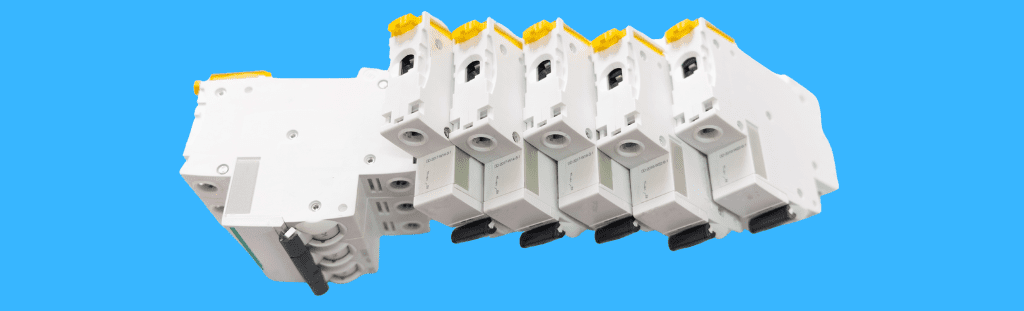

Switch fuse

Switch fuses are a type of electrical fuse that can be externally controlled using a switch handle.

In common applications in high voltage environments, you control whether the fuses pass power or not by toggling the switch to the on or off position.

Push-out fuse

Push-out fuses use boron gas to limit the arcing process. They are used in high voltage environments, especially in 10 kV transformers.

When the fuse melts, the boron gas extinguishes the arc and is expelled through the hole in the tube.

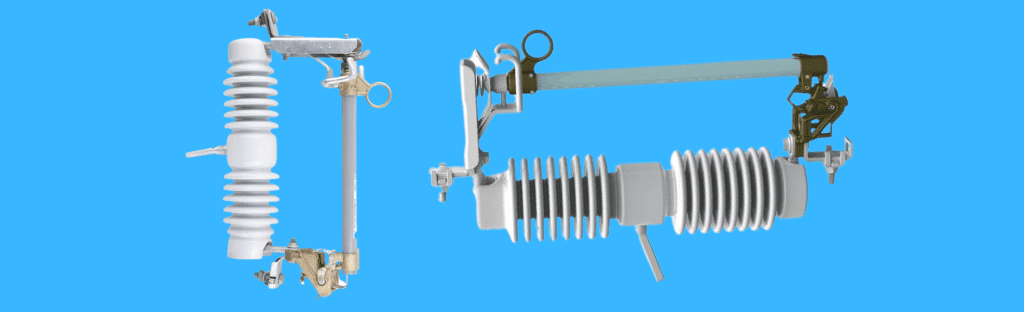

Turn off the fuse

Drop-out fuses are a type of pull-out fuses where the fuse link is separated from the fuse body. These fuses consist of two main parts; housing cutout and fuse holder.

The fuse holder houses a fusible link, and the cutout body is a porcelain frame that supports the fuse holder through the top and bottom contacts.

The fuse holder is also held at an angle to the cutout body and this is done for a reason.

When the fuse link melts due to overcurrent or short circuit, the fuse holder is disconnected from the body of the cutout on the top contact. This causes it to fall under gravity, hence the name "drop fuse".

A falling fuse holder is also a visual sign that a fuse has blown and needs to be replaced. This type of fuse is commonly used to protect low voltage transformers.

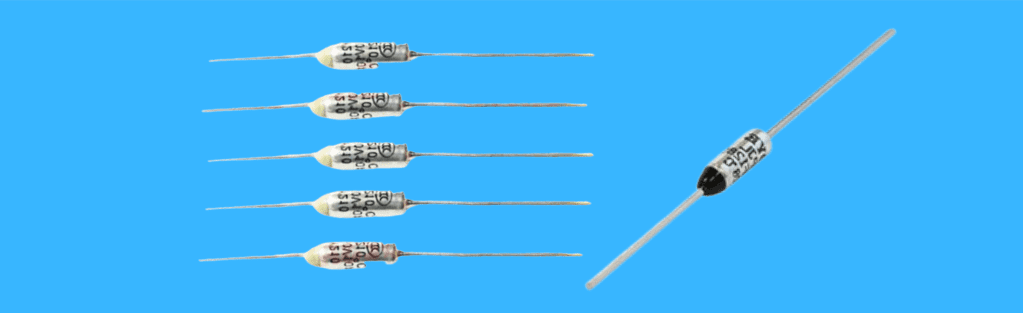

Thermal fuse

The thermal fuse uses temperature signals and elements to protect against overcurrent or short circuit. This type of fuse, also known as a thermal cutout and widely used in temperature sensitive devices, uses a sensitive alloy as the fuse link.

When the temperature reaches an abnormal level, the fusible link melts and cuts off power to other parts of the instrument. This is primarily done to prevent fire.

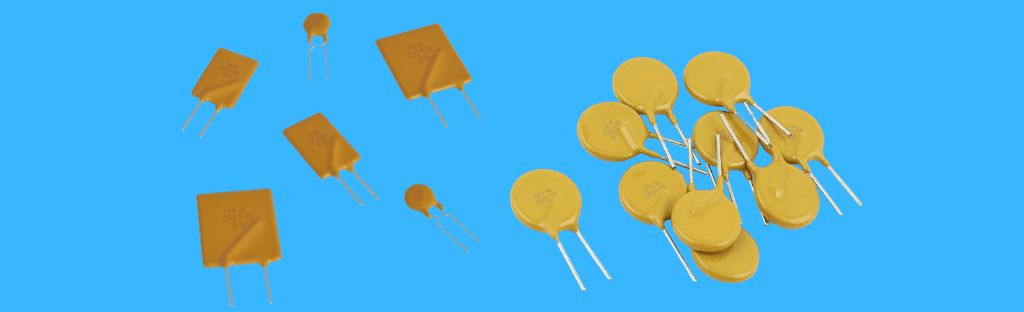

Resettable fuse

Resettable fuses are also called positive temperature coefficient (PPTC) polymer fuses, or "polyfuses" for short, and have features that make them reusable.

This type of fuse consists of a non-conductive crystalline polymer mixed with conductive carbon particles. They operate with temperature for overcurrent or short circuit protection.

When cold, the fuse remains in a crystalline state, which keeps the carbon particles close together and allows energy to pass through.

In the case of excessive current supply, the fuse heats up, changing from a crystalline form to a less compact amorphous state.

The carbon particles are now farther apart, which limits the flow of electricity. Energy still flows through this fuse when activated, but is usually measured in the milliamp range.

When the circuit cools down, the compact crystal state of the fuse is restored and power flows unhindered.

From this you can see that the Polyfuses are automatically reset, hence the name "resettable fuses".

They are commonly found in computer and telephone power supplies, as well as in nuclear systems, air travel systems, and other systems where replacing parts would prove extremely difficult.

semiconductor fuse

Semiconductor fuses are ultra fast fuses. You use them to protect semiconductor components in a circuit, such as diodes and thyristors, because they are sensitive to small current surges.

They are commonly used in UPSs, solid state relays and motor drives, as well as other devices and circuits with sensitive semiconductor components.

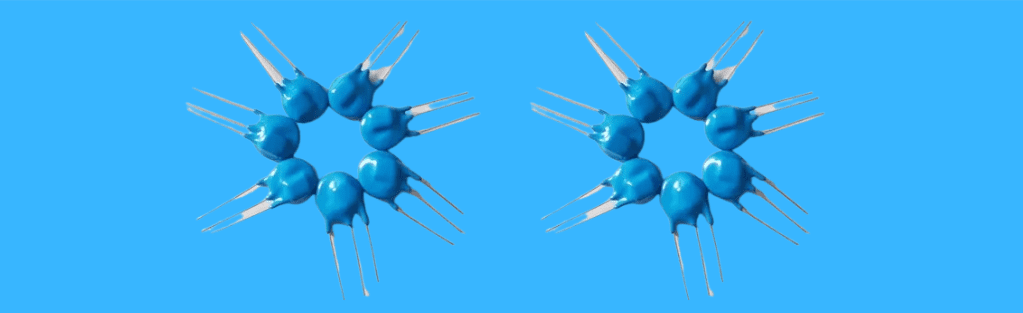

Surge suppression fuse

Surge protection fuses use temperature signals and temperature sensors to protect against power surges. A good example of this is a negative temperature coefficient (NTC) fuse.

NTC fuses are installed in series in the circuit and decrease their resistance at higher temperatures.

This is the exact opposite of PPTC fuses. During peak power, the reduced resistance causes the fuse to absorb more power, which reduces or "suppresses" the power flowing.

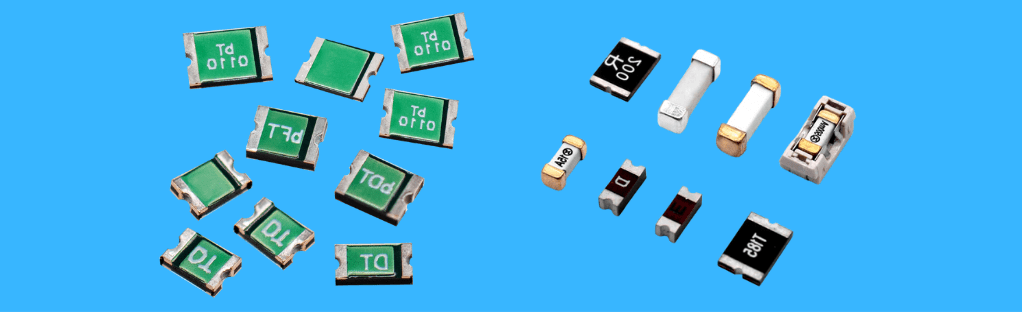

Surface Mount Device Fuse

Surface mount (SMD) fuses are very small electrical fuses commonly used in low current environments with limited space. You see their applications in DC devices such as mobile phones, hard drives, and cameras, among others.

SMD fuses are also called chip fuses and you can also find high current variants of them.

Now all types of fuses mentioned above have a few additional characteristics that determine their behavior. These include rated current, rated voltage, fuse operating time, breaking capacity and I2T value.

Guide Video

How Fuse Rating is Calculated

The current rating of fuses used in standard operating devices is usually set between 110% and 200% of their circuit rating.

For example, fuses used in motors are typically rated at 125%, while fuses used in transformers are rated at 200%, and fuses used in lighting systems are rated at 150%.

However, they depend on other factors such as circuit environment, temperature, sensitivity of protected devices in the circuit, and many others.

For example, when calculating the fuse rating for a motor, you use the formula;

Fuse Rating = {Wattage (W) / Voltage (V)} x 1.5

If the power is 200W and the voltage is 10V, fuse rating = (200/10) x 1.5 = 30A.

Understanding the electric arc

Having read up to this point, you must have come across the term "electric arc" several times and understood that it is necessary to prevent it when the fusible link melts.

An arc is formed when electricity bridges a small gap between two electrodes through ionized gases in the air. The arc does not go out unless the power is turned off.

If the arc is not controlled by distance, non-conductive powder and/or liquid materials, you risk continuous overcurrent in the circuit or fire.

If you want to know more about fuses, please visit this page.

F.A.Q.

How many types of AC fuses are there?

There are two main categories of AC fuses: low voltage fuses and high voltage fuses.

Which can then be divided into 11 or more different types.

How many types of fuses do we have in electrical engineering?

More than 11 types of fuses are used in electrical systems, which are divided into main categories of AC and DC fuses. Fuses are also classified into high and low voltage subcategories.