High-pressure fuel pump: what is it in a car? Diesel and Petrol

In articles on the Vodi.su website, we use various abbreviations. So, in a recent article about the timing belt, we said that the generator belt transmits rotation from the crankshaft to various units, including the injection pump. What is hidden under this abbreviation?

These letters mean: a high pressure fuel pump, a very important unit that is installed on almost all modern cars. At first, it was used exclusively on diesel power units. Today it can also be found in gasoline engines with a distributed injection type.

Why do you need a high-pressure fuel pump?

If you turn the history of the automotive industry, you can see that the carburetor was first responsible for the distribution of fuel among the cylinders. But already from the beginning of the 80s of the XX century, injection systems began to replace it. The thing is that the carburetor has one significant drawback - with its help it is impossible to supply clearly measured portions of the fuel-air mixture into the combustion chambers of the pistons, which is why the consumption was high.

The injector provides an individual supply of the mixture to each of the cylinders. Thanks to this factor, cars began to consume less fuel. This became possible due to the widespread use of high-pressure fuel pumps. Hence, we come to the conclusion that the main purpose of the fuel pump is to supply the necessary portions of fuel assemblies to the cylinders. And since this pump is directly connected to the crankshaft, when the speed drops, the portion volumes decrease, and during acceleration, on the contrary, they increase.

Principle of operation and device

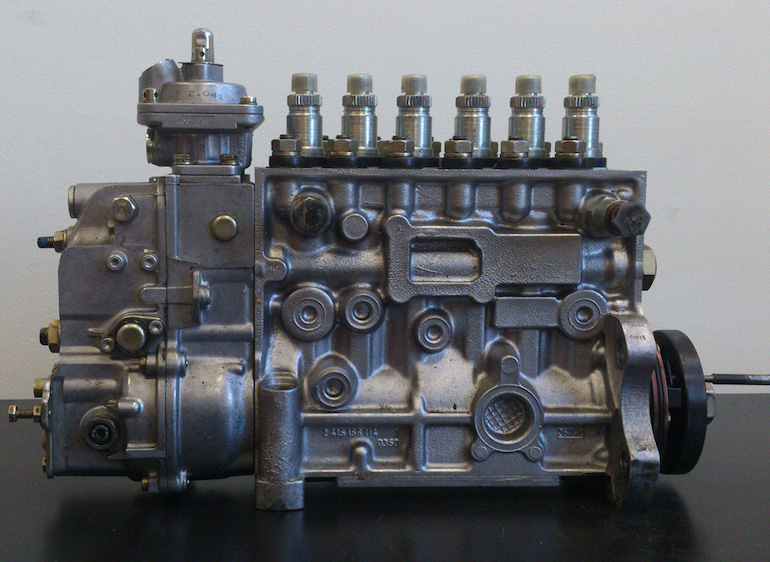

The device may seem complicated at first glance:

- plunger pairs, consisting of a plunger (piston) and a cylinder (sleeve);

- fuel is supplied to each plunger pair through channels;

- camshaft with centrifugal clutch - rotates from the timing belt;

- plunger pushers - the cams of the shaft press on them;

- return springs - return the plunger to its original position;

- discharge valves, fittings;

- toothed racks and an all-mode regulator controlled by the gas pedal.

This is a schematic, simplest description of an in-line injection pump. Knowing the device, it is not difficult to guess how this whole system functions: the camshaft rotates, its cams press on the plunger pushers. The plunger rises up the cylinder. The pressure rises, which opens the discharge valve and through it the fuel flows to the injector.

In order for the volume of the mixture to correspond to the operating modes of the engine, additional equipment is used. So, due to the rotation of the plunger, not the entire fuel mixture is directed to the injectors, but only part of it, while the rest leaves through the drain channels. The centrifugal injection advance clutch is used to supply fuel to the injectors at the exact moment in time. An all-mode regulator is also used, connected through a spring to the gas pedal. If you step on the gas, more fuel is injected into the cylinders. If you hold the pedal in a stable position or loosen, the amount of mixture decreases.

It is worth noting that in more modern cars, all adjustments are not made mechanically from the pedal; the injection volumes are monitored by electronics associated with various sensors. If, for example, you need to accelerate, appropriate impulses are sent to the actuators, and a strictly measured volume of fuel enters the cylinders.

Types

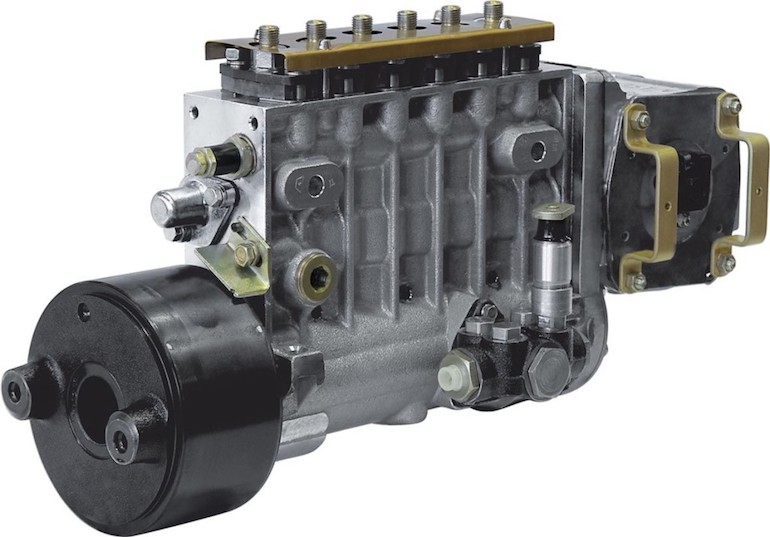

This topic is quite extensive. Above, we have described only the simplest in-line type of injection pump. The auto industry does not stand still and today different types of high pressure pumps are used everywhere:

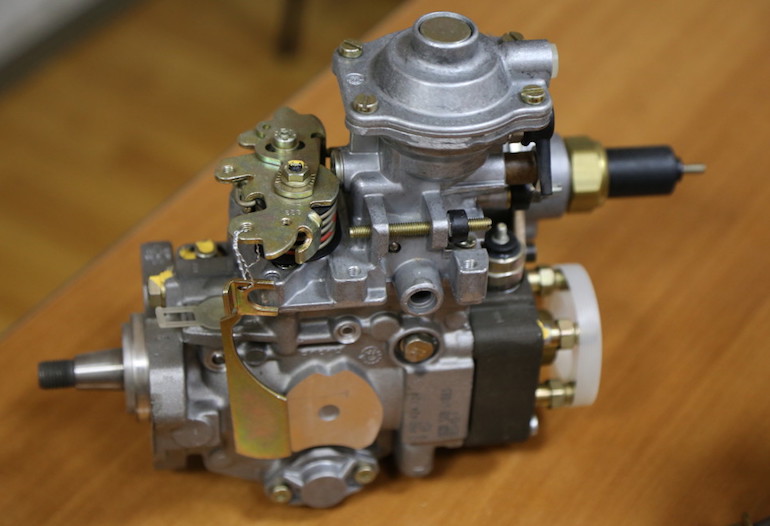

- distribution - have one or two plungers for supplying the mixture to the fuel rail, there are fewer plunger pairs than the number of cylinders in the engine;

- Common Rail is a main-line system similar in principle to distribution injection pumps, but differs in a more complex device and high fuel supply pressure;

- Fuel injection pump with a hydraulic accumulator - the fuel assembly is fed from the pump to the hydraulic accumulator, and then is sprayed through the nozzles along the cylinders.

Interestingly, it is the ordinary in-line injection pumps that are recognized as the most reliable and durable. In turn, Common Rail systems are distinguished by a very complex structure and strict requirements for the quality of diesel fuel. High pressure fuel pumps with a hydraulic accumulator are not widely used at all.

Of course, thanks to the use of injectors with solenoid valves in common rail systems, which operate according to complex programs, such engines are economical. Diesel engines of this type consume literally 3-4 liters of diesel fuel even in the city.

But maintenance is also too expensive:

- regular diagnostics;

- the use of expensive engine oil recommended by the manufacturer;

- if there are even the slightest mechanical particles and abrasives in the fuel, then precision parts and plunger pairs will fail very quickly.

Therefore, we recommend refueling only in the networks of proven gas stations with a high-quality diesel engine if you have a car with a Common Rail system.

Loading…