Valve lifter in internal combustion engines - when is a valve replacement required?

Content

- Valve lifters and their design

- Hydraulic valve lifters - principle of operation

- Hydrodistributor tappet - can it be damaged?

- Valve clearance in internal combustion engines

- Damaged car valve lifters - signs of wear

- How to check hydraulic lifters in a car?

- Valve lifter - cost of spare parts and replacement

- Self-replacement of valve lifters

- Valve lifter without hydraulic backlash compensation

Each valve lifter is responsible for compensating for valve clearance. This reduces the distance between the top of the pushrod and the shaft cam. It has a decisive influence on the opening time of the valves and their correct closing. Therefore, the valve lifter must be in working condition and provide the factory valve clearance in internal combustion engines. Find out how it works and when you notice something is wrong with it and needs to be replaced. See if you can manage to replace this item yourself!

Valve lifters and their design

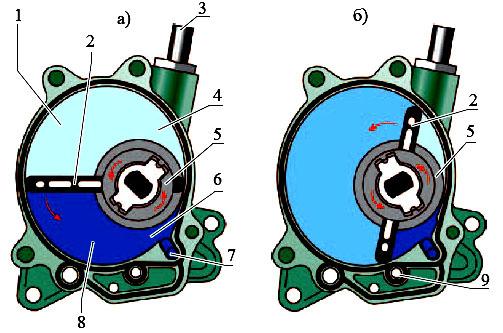

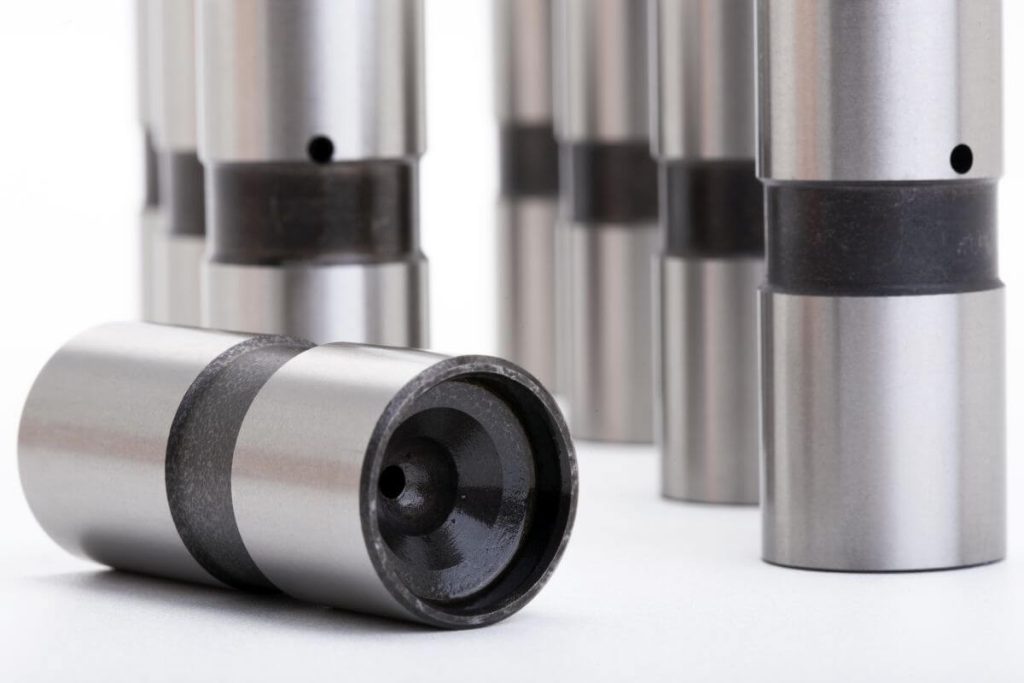

Valve cups - as these elements are also called - have a simple design. They usually consist of:

- the body;

- piston;

- low and high pressure chambers;

- check valve;

- oil pad;

- springs.

This is the design of hydraulic valve lifters that are used in most engines currently produced. Their undeniable advantage is the lack of maintenance. However, there are manufacturers of tappets without hydraulics, and they need to be adjusted periodically. This may be inconvenient, but such a valve lifter will be much simpler and more durable.

Hydraulic valve lifters - principle of operation

How does a hydraulic pusher work in an engine? The pressure of the camshaft cam on the top of the tappet causes the check valve to close and increase the pressure. Thanks to this, the valve clearance is canceled, and the valve can operate at the right time. When the shaft cam is lowered and no longer touches the pusher, the valve opens and the pressure in the chambers equalizes. After that, the valve can be closed and returned to its original position.

Hydrodistributor tappet - can it be damaged?

Can a hydraulic lifter fail? Definitely yes, which is why regular replacement is necessary. A valve lifter that runs on engine oil can fail if contaminated. This is a relatively small component that is subjected to significant loads and fluctuating temperatures, and therefore requires care in operation. It is worth using very good quality engine oils and changing them regularly. Even slight dirt can clog the channels in the pushers and block their operation.

What Causes Valve Tappet Problems?

In addition, over time, the pushers of the hydraulic distributors wear out. The piston, spring, or oil pads may be worn out and engine oil will begin to seep into the combustion chamber. Valve clearance compensation may also not be as effective, as can be seen from the behavior of the engine. To understand this, it is worth explaining what valve clearance is.

Valve clearance in internal combustion engines

The valve lifter is connected to the gap. Why couldn't the engine's cams directly touch and control the valves? This is not possible for several reasons. One of the most important is the behavior of metals under the influence of operating temperature. Automotive timing parts expand when heated, which reduces the distance between individual parts. Controlling valve opening and closing times requires a mechanism with visible valve clearance that can be equalized as the engine warms up and cools down. Otherwise, during operation of the unit, the valves would not close and a collision with the pistons or a drop in compression could occur.

Damaged car valve lifters - signs of wear

If you have damaged or worn tappets in your car, the symptoms are visible in the culture of engine operation. At idle, when the engine is cold, the operation of the unit may be disturbed. The revs will not be constant and the compression will drop, due to too small valve clearance. As a result, the valves do not close, which is immediately felt in the form of a decrease in vehicle dynamics. In addition to too little clearance, the valve lifter can also cause too much clearance. Then you will hear metal knocks during operation. When the blocks heat up, they stop as the expansion of the metal removes the excess play.

How to check hydraulic lifters in a car?

Usually these elements do not fail suddenly, but gradually lose their properties. Therefore, an inexperienced driver may not hear or see changes in engine operation. However, it is useful to see how a cold engine works:

- whether it maintains a stable turnover;

- is there a problem with compression;

- is there a distinct difference in operation on a cold and warm engine;

- does it make any other sounds right after launch.

Valve lifter - cost of spare parts and replacement

How much does it cost to replace hydraulic lifters? The cost of one part is not too high. In popular diesel engines, such an element can cost from a few to several zlotys apiece. Remember, however, that usually the replacement covers all components, and not, for example, 2 out of 8 or 16. One valve pusher is selected for one valve, so if, for example, there are 16 of them in the head, then 16 pushers need to be bought in the store. In addition, you also get rid of the gasket under the valve cover, which costs an extra ten zlotys. A good mechanic will also advise changing the engine oil. Thus, everything together with work can approach the border of 800-100 euros.

Self-replacement of valve lifters

It is usually best to replace the pushers in proven workshops. Of course, you can do it yourself and there is no great philosophy in this, but you need to have a lot of knowledge about the design and operation of the engine. If the valve lifter is damaged, it is necessary to remove the valve cover and unscrew the camshaft (or shafts). The disassembly itself is not too difficult, but re-installing these elements in the correct position can be a problem for the hobbyist.

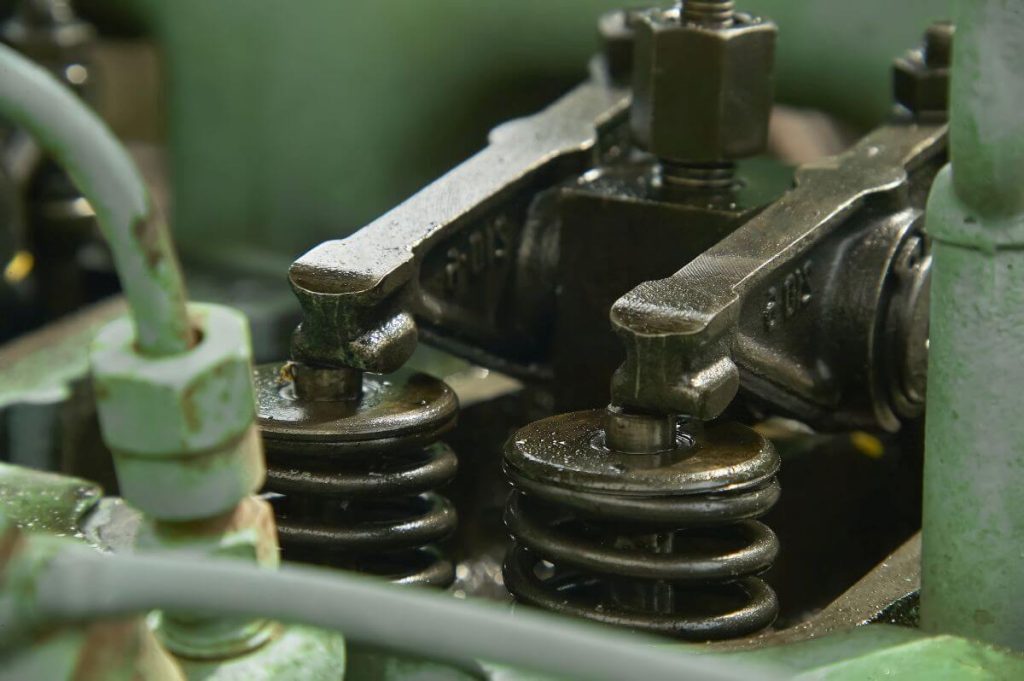

Valve lifter without hydraulic backlash compensation

Some Honda and Renault engines have mechanically adjustable valve clearance. The valve tappet is not filled with oil, and its operation is based on special plates or elements fastened with screws. The gap is adjusted using additional plates or a feeler gauge with which you can check the distance. For some power units, the work does not need to be repeated too often (usually every 60-000 km). However, in the case of engines running on gas, sometimes it is necessary to adjust the gap 100 times more often! And this requires almost an annual removal of the cover and adjustment of valve clearances.