Car window tinting with perforated film

Content

Window tinting severely limits visibility from the car and creates inconvenience for others, from neighboring drivers in the stream to law enforcement officers. Nevertheless, you still have to escape from direct sunlight, and the law limits light transmission only in the front hemisphere. One of the means of tinting was a thin plastic film with small holes over the entire area - perforated.

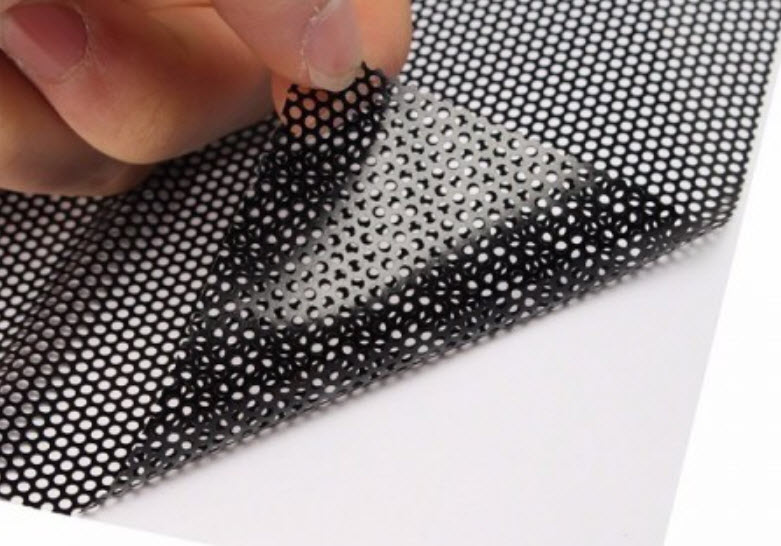

What is perforated film

A polymer film made of vinyl (polyvinylchloride) or polyethylene is subjected to perforation. The thickness is usually 100 to 200 microns. Over the entire area, a lot of geometrically correctly applied holes are made on it mechanically or thermally with a small distance between them.

The diameter of the holes is about one millimeter. The total area of the material is thus reduced by about half, which allows a partial passage of light.

Layers of glue and paint are also applied to the film. The adhesive side is usually black, so from the inside the film simply changes the light intensity without giving any additional color. In applications other than automotive, it is possible to use multilayer films with a double-sided pattern or color tint.

From the outside, the film looks like a monochrome painted or patterned. Moreover, thanks to this physical principle of dimming, the pattern will be visible only from the outside.

Purpose

The coating is used to reduce illumination inside rooms and car interiors while maintaining sufficient visibility from the inside. It is possible to apply advertising or decorative images on the outside.

Additionally, the film provides some protection to the glass. It itself can be removed without a trace in case of damage and replaced, and the glass is protected from scratches and small chips. In case of severe damage, the glued plastic is able to hold glass fragments on itself, which increases safety.

Price

The cost of the coating material can be indicated in rubles per unit area, linear meter with an indication of the width of the roll or per kilogram of mass.

Prices are highly dependent on the specific product:

- manufacturer and quality;

- thickness and strength of the material;

- the presence or absence of a pattern, coloration and properties of the adhesive layer.

The cost ranges from about 200 rubles per square meter to 600 or more.

Shelf life

A film from a good manufacturer can last 5-7 years, the cheapest versions live no more than one season of operation. The adhesive layer does not withstand, the paint fades, the base cracks and collapses.

Can it be used on car windows and headlights

The law does not regulate exactly how tinting is performed, as well as the transparency of the rear hemisphere windows in general. And for the front, no perforated film is suitable, since its light transmission will be obviously lower than allowed by the standards for vehicles.

In addition, perforation can give various lighting effects that tire the eyesight. There is no exact information about the usefulness of just such a method of toning for visual acuity, although this is sometimes claimed.

Drawing on headlights is illegal and devoid of any practical meaning. Reservation of lighting devices from damage is carried out by other materials.

Do-it-yourself installation of perforated film

To ensure the quality of the application, it is better to entrust the process to professionals, but you can do it yourself.

- You need to purchase a film specially designed for pasting car windows. It must be laminated on the outside so that the perforated holes are not exposed to water and dirt, and to preserve the pattern, if any.

- The ambient air during operation must be clean and dry, the ingress of moisture and dust on the glass is unacceptable. The surface is prepared by thorough washing, degreasing and drying.

- Gluing is done from top to bottom and from the middle to the edges. It is unacceptable to overlap adjacent parts; the transition zone will lead to delamination of the coating.

- The adhesive layer does not require drying or polymerization, the coating is immediately ready for use.

If necessary, the plastic is easy to remove, especially if you use a steamer. Glue usually does not remain, but if this happens, then the residue is removed with alcohol-based window cleaners.

Advantages and disadvantages

The advantages of a perforated coating include:

- effective shading of the cabin while maintaining visibility from the inside;

- the possibility of obtaining a uniform color on the outside or a decorative pattern;

- placement of advertising on the windows of the car while maintaining the view and invisibility of the picture from the opposite side;

- selection of the desired degree of tinting by the size and density of perforated holes;

- ease of application of self-adhesive film, ease of removal and replacement;

- giving the glass extra protection.

There is only one drawback - the deterioration of visibility, and when applying artistic images, this is a short life of the picture, which will be a pity to part with.