Turbocompound - what is it? Principle of operation

Content

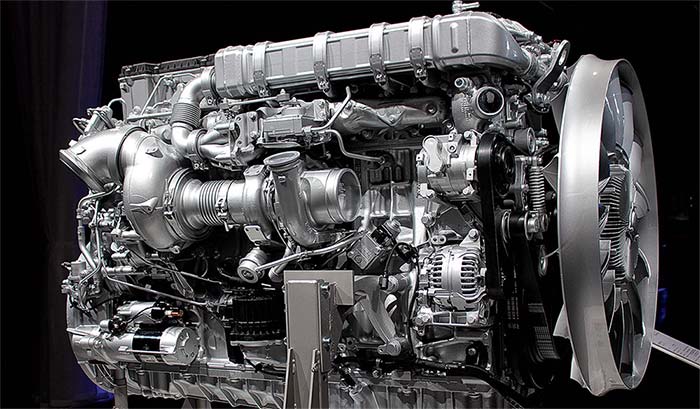

To improve the efficiency of power units, manufacturers are developing various mechanisms and devices. Among them is a turbocompound. Let's figure out what kind of device it is, how a turbocompound engine works and what its advantages are.

What is turbocompound

This modification is used on a diesel engine. In a classic form, the engine has a turbine that uses exhaust gases to increase the air pressure in the intake manifold.

The gas turbine provides better combustion of HTS in the cylinders, due to which the atmosphere receives less harmful substances, and the engine acquires increased power. However, this mechanism uses only a fraction of the energy released when the exhaust gases leave the exhaust manifold.

Here are some numbers. The exhaust gas temperature at the outlet of the engine can reach about 750 degrees. As the gas passes through the turbine, it spins the blades, which gives the motor an additional amount of fresh air. At the outlet of the turbine, the gases are still hot (their temperature drops by only a hundred degrees).

The remaining energy is used by a special block through which the exhaust goes. The device converts this energy into mechanical action, which increases the rotation of the crankshaft.

appointment

The essence of the compound block is to increase the power of the crankshaft due to energy that is simply removed into the atmosphere in a conventional engine. The diesel gets an additional torque boost, but does not use additional fuel.

How the turbo compound works

Classic turbocharging consists of two mechanisms. The first is gas, the impeller of which is set in motion due to the fact that pressure is created in the exhaust tract. The second mechanism is a compressor associated with the first element. Its purpose is to pump fresh air into the cylinders.

At the heart of the additional unit, a power turbine is used, which is behind the main one. To eliminate the huge difference between the rotation of the turbo compound and the flywheel, a hydraulic element is used - a clutch. Its slippage ensures the matching of the torque coming from the device and the engine crankshaft.

Here is a short video of how one of the modifications of Volvo turbocompound engines works:

Turbo compound operation scheme

Here is a quick diagram of how a turbo compound engine works. First, exhaust gas enters the cavity of the turbocharger, spinning the main turbine. Further, the flow rotates the impeller of this mechanism. Moreover, the speed can reach 100 thousand per minute.

A compound block is installed behind the supercharger circuit. A stream enters its cavity, spinning its turbine. This figure reaches 55 thousand per minute. Next, a fluid coupling and a reduction gear connected to the crankshaft are used. Without a fluid coupling, the device will not be able to provide a smooth increase in the power of the internal combustion engine.

The scania engine has such a scheme. This process is used to operate the power plant DT 1202. The classic turbocharged diesel engine was able to develop power within 420hp. After the manufacturer upgraded the power unit with a turbo compound system, its performance increased by 50 horses.

Advantages and disadvantages

The peculiarity of the innovative development made it possible to achieve such positive results:

- Decent increase in engine efficiency, but at the same time the crankshaft does not spin more than usual;

- During operation, the installation does not require additional fuel, which does not make the car more voracious;

- Due to the presence of a hydraulic coupling, the stability of the unit is ensured with a sharp change in load;

- The engine runs much smoother because the power increase is provided by more efficient crankshaft rotation, but not due to jolts from the crank mechanism;

- The durability of the unit does not decrease, as if a turbine were installed on a conventional engine. On the contrary, due to the unloading of the piston mechanism, its working resource increases.

The disadvantages include the fact that a lot of money was spent on the development and additional installation will also require payment for engine modernization. In addition to the high cost of the engine itself, its design becomes more complicated. Because of this, maintenance and, if necessary, repairs become more expensive, and it is more difficult to find a master who clearly understands the installation device.

We offer a small test drive of a turbocompound diesel engine:

Watch this video on YouTube

One comment

anonym

FOREWORD

This maintenance manual is designed to serve as a reference for DOOSAN Infracore (here

after DOOSAN’s) customers and distributors who wish to gain basic product knowledge on

DOOSAN's DL08 Diesel engine.

This economical and high-performance diesel engine (6 cylinders, 4 strokes, in-line, direct

injection type) has been so designed and manufactured to be used for the overland transport

or industrial purpose. That meets all the requirements such as low noise, fuel economy, high

engine speed, and durability.

To maintain the engine in optimum condition and retain maximum performance for a long

time, CORRECT OPERATION and PROPER MAINTENANCE are essential.

In this manual, the following symbols are used to indicate the type of service operations to be

performed.