Heavy tank IS-7

Heavy tank IS-7

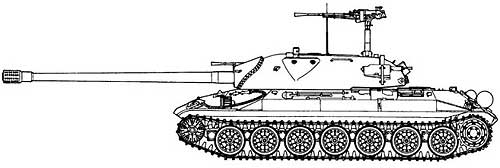

The frontal part is trihedral, like the IS-3, but not so much protruding forward. As a power plant, it was planned to use a block of two V-16 diesel engines with a total capacity of 1200 hp. With. The electric transmission was similar to that installed on the IS-6. The fuel tanks were located in the sub-engine foundation, where, due to the side sheets of the hull bevelled inward, an empty space was formed. The armament of the IS-7 tank, which consisted of a 130-mm S-26 gun, three machine guns DT and two 14,5 mm Vladimirov machine guns (KPV), was located in a cast flattened turret. Despite the large mass - 65 tons, the car turned out to be very compact. A full-size wooden model of the tank was built. In 1946, the design of another version began, which had the same factory index - 260. In the second half of 1946, according to the drawings of the design department of tank production, two prototypes of object 100 were manufactured in the shops of the Kirov Plant and a branch of Plant No. 260. The first of them was assembled on September 8 1946, passed 1000 km on sea trials by the end of the year and, according to their results, met the main tactical and technical requirements.

A maximum speed of 60 km / h was reached, the average speed on a broken cobblestone road was 32 km / h. The second sample was assembled on December 25, 1946 and passed 45 km during sea trials. In the process of designing a new machine, about 1500 working drawings were made, more than 25 solutions were introduced into the project, which had not been previously encountered in tank building, more than 20 institutes and scientific institutions were involved in the development and consultations. Due to the lack of a 1200 hp engine. with. it was supposed to install in the IS-7 a twin installation of two V-16 diesel engines from plant number 77. At the same time, the Ministry of Transport Engineering of the USSR (Mintransmash) instructed plant number 800 to produce the necessary engine. The plant did not fulfill the assignment, and the twin unit of plant No. 77 was late by the deadlines approved by the Ministry of Transport. In addition, it has not been tested and tested by the manufacturer. Tests and fine-tuning were carried out by a branch of the plant No. 100 and revealed its complete constructive unsuitability. Lacking the necessary engine, but striving to fulfill the government's task on time, the Kirov plant, together with the plant No. 500 of the Minaviaprom, began to create a TD-30 tank diesel engine based on the aircraft ACh-300. As a result, the TD-7 engines were installed on the first two IS-30 samples, which showed their suitability during the tests, but due to poor assembly they required fine-tuning. When working on the power plant, a number of innovations were partially implemented and partially tested in laboratory conditions: soft rubber fuel tanks with a total capacity of 800 liters, fire-fighting equipment with automatic thermal switches that operated at a temperature of 100 ° -110 ° C, an ejection engine cooling system. The tank's transmission was designed in two versions.

The first, manufactured and tested in the IS-7, had a six-speed gearbox with carriage shifting and synchronizers. The rotation mechanism is planetary, two-stage. The control had hydraulic servos. During tests, the transmission showed good traction qualities, providing high vehicle speeds. The second version of the six-speed manual transmission was developed jointly with the Moscow State Technical University named after N. E. Bauman. The transmission is planetary, 4-speed, with a tig ZK turning mechanism. Tank control facilitated by hydraulic servo drives with a promising gear selection. During the development of the undercarriage, the design department designed a number of suspension options manufactured and subjected to laboratory running tests on serial tanks and on the first experimental IS-7. Based on these, the final working drawings of the entire chassis were developed. For the first time in the domestic tank building, caterpillars with a rubber-metal hinge, double-acting hydraulic shock absorbers, road wheels with internal shock absorption, operating under heavy loads, and beam torsion bars were used. A 130 mm S-26 cannon was installed with a new slotted muzzle brake. A high rate of fire (6 rounds per minute) was ensured by the use of a loading mechanism.

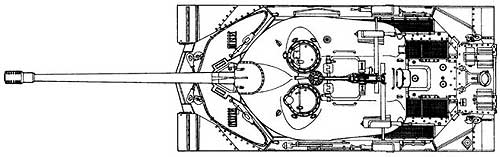

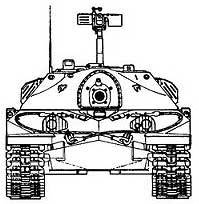

The IS-7 tank housed 7 machine guns: one 14,5-mm caliber and six 7,62-mm calibers. A remote synchronously-servo electric machine gun mount was manufactured by the laboratory of the chief designer of the Kirov Plant using individual elements of equipment of foreign technology. The fabricated sample of the turret mount for two 7,62-mm machine guns was mounted on the rear of the turret of an experimental tank and was tested, ensuring high maneuverability of machine-gun fire. In addition to two samples assembled at the Kirov Plant and undergoing sea trials in late 1946 - early 1947, two more armored hulls and two turrets were manufactured at the Izhora Plant. These hulls and turrets were tested by shelling from 81-mm, 122-mm and 128-mm caliber guns at the GABTU Kubinka training ground. The test results formed the basis for the final armor of the new tank. During 1947, intensive work was underway at the design bureau of the Kirov Plant to create a project for an improved version of the IS-7. The project retained a lot from its predecessor, but at the same time, many significant changes were made to it. The hull became a little wider, and the turret became more flattened. The IS-7 received curved hull sides proposed by designer G. N. Moskvin. The armament was reinforced, the vehicle received a new 130-mm S-70 cannon with a long barrel of 54 caliber. Her projectile weighing 33,4 kg left the barrel with an initial speed of 900 m/s. A novelty for its time was the fire control system. The fire control device ensured that the stabilized prism was aimed at the target regardless of the gun, the gun was automatically brought to the stabilized aiming line when fired, and the shot was fired automatically. The tank had 8 machine guns, including two 14,5 mm KPVs. One large-caliber and two RP-46 7,62-mm calibers (a modernized post-war version of the DT machine gun) were installed in the gun mantlet. Two more RP-46s were on the fenders, the other two, turned back, were attached outside along the sides of the aft part of the tower. All machine guns are remote controlled.

Ammunition consisted of 30 rounds of separate loading, 400 rounds of 14,5 mm and 2500 rounds of 7,62 mm. For the first samples of the IS-7, together with the Research Institute of Artillery Weapons, for the first time in the domestic tank building, ejectors made of milled armor plates were used. Moreover, five different models of ejectors underwent preliminary tests at the stands. An inertial dry cloth air filter was installed with two stages of cleaning and automatic dust removal from the hopper using the energy of the exhaust gases. The capacity of the soft fuel tanks, made of special fabric and withstanding pressure up to 0,5 atm., Was increased to 1300 liters. A version of the transmission was installed, developed in 1946 in conjunction with the MVTU im. Bauman. The undercarriage included seven large-diameter road wheels on board and did not have support rollers. The rollers were double, with internal cushioning. To improve the smoothness of the ride, double-acting hydraulic shock absorbers were used, the piston of which was located inside the suspension balancer. The shock absorbers were developed by a group of engineers led by L. 3. Schenker. The caterpillar 710 mm wide had cast box-section track links with a rubber-metal hinge. Their use made it possible to increase durability and reduce driving noise, but at the same time they were difficult to manufacture.

The automatic fire extinguishing system designed by M.G.Shelemin consisted of sensors and fire extinguishers installed in the engine-transmission compartment, and was designed to be switched on three times in case of fire. In the summer of 1948, the Kirovsky plant manufactured four IS-7s, which, after factory tests, were transferred to the state. The tank made a strong impression on the members of the selection committee: with a mass of 68 tons, the car easily reached a speed of 60 km / h, and had excellent cross-country ability. His armor protection at that time was practically invulnerable. Suffice it to say that the IS-7 tank withstood shelling not only from a 128-mm German cannon, but also from its own 130-mm gun. Nevertheless, the tests were not without an emergency. So, during one of the shellings at the firing range, the projectile, sliding along the bent side, hit the suspension block, and it, apparently weakly welded, bounced off the bottom along with the roller. During the run of another car, the engine, which had already worked out the warranty period during the tests, caught fire. The fire extinguishing system gave two flashes to localize the fire, but could not extinguish the fire. The crew abandoned the car and it burned down completely. But, despite a number of criticisms, in 1949 the military gave the Kirov Plant an order to manufacture a batch of 50 tanks. This order was not fulfilled for unknown reasons. The Main Armored Directorate blamed the plant, which, in its opinion, in every possible way delayed the production of equipment and devices necessary for mass production. The factory workers referred to the military, who “hacked to death” the car, demanding to reduce the weight to 50 tons. Only one thing is known for certain, none of the 50 ordered cars left the factory workshops. The performance characteristics of the heavy tank IS-7

For the new tank, the Kirov Plant developed a loading mechanism similar to marine installations, which had an electric drive and small dimensions, which, together with the results of testing the turret by shelling and the comments of the GABTU commission, made it possible to create a more rational turret in terms of projectile resistance. The crew consisted of five people, four of which were located in the tower. The commander was to the right of the gun, the gunner to the left and two loaders behind. The loaders controlled the machine guns located in the rear of the tower, on the fenders and the large-caliber machine guns on the anti-aircraft gun. As a power plant on the new version of the IS-7, a serial marine 12-cylinder diesel engine M-50T with a capacity of 1050 liters was used. With. at 1850 rpm. He had no equal in the world in terms of the totality of the main combat indicators. With a combat weight similar to that of the German “King Tiger”, the IS-7 was significantly superior to this one of the strongest and heaviest production tank of the Second World War, created two years earlier, both in terms of armor protection and armament. It remains only to regret that the production this unique combat vehicle was never deployed. Sources:

| ||||||||||||||||||||||||||||||||||||||||||||

At the end of 1944, the design bureau of the Experimental Plant No. 100 began sketching a new heavy tank. It was assumed that this machine would embody all the experience gained in the design, operation and combat use of heavy tanks during the war. Not finding support from the People's Commissar of Tank Industry V.A.Malyshev, the director and chief designer of the plant, Zh. Ya. Kotin, turned to the chief of the NKVD L.P. Beria for help.

At the end of 1944, the design bureau of the Experimental Plant No. 100 began sketching a new heavy tank. It was assumed that this machine would embody all the experience gained in the design, operation and combat use of heavy tanks during the war. Not finding support from the People's Commissar of Tank Industry V.A.Malyshev, the director and chief designer of the plant, Zh. Ya. Kotin, turned to the chief of the NKVD L.P. Beria for help.

On the roof of the tower on a special rod, a second large-caliber machine gun was installed, equipped with a synchronous-tracking remote electric guidance drive tested on the first experimental tank, which made it possible to fire at both air and ground targets without leaving the tank. In order to increase the firepower, the designers of the Kirov plant on an initiative basis developed a built version (1x14,5-mm and 2x7,62-mm) anti-aircraft machine gun mount.

On the roof of the tower on a special rod, a second large-caliber machine gun was installed, equipped with a synchronous-tracking remote electric guidance drive tested on the first experimental tank, which made it possible to fire at both air and ground targets without leaving the tank. In order to increase the firepower, the designers of the Kirov plant on an initiative basis developed a built version (1x14,5-mm and 2x7,62-mm) anti-aircraft machine gun mount.