Installation of gas equipment on a car

Converting a car to gas is considered one of the ways to save on fuel. There are a lot of factors that will testify both for the installation of gas-cylinder equipment and against it. It all depends on the operating conditions of the car, the average monthly mileage, the cost of the equipment itself, and so on. Any tangible savings can be obtained only if you wind at least one and a half to two thousand per month. If the car is used exclusively for commuting, then the installation of HBO will pay off very, very soon.

Also important is such a moment as the fuel consumption of the car. For example, installing HBO on cars of classes “A” and “B” is not economically profitable. As a rule, such cars do not differ in increased consumption of gasoline, and with the transition to gas, engine power will drop and gas consumption will increase, respectively, the difference will be minimal, mere pennies per hundred kilometers.

Also, drivers of compact hatchbacks will have to say goodbye to the trunk forever - they already have it small, and the balloon will take up all the remaining space.

Also, the transition to GAS is not very beneficial for owners of passenger cars with diesel engines, since savings can be obtained only with intensive use of the car, and again, you will not feel the savings with constant trips around the city. There is also a common myth that diesel and turbo engines cannot be converted to gas. It is not true. You can convert to gas, but the cost of equipment will be quite high.

For turbocharged engines, it is necessary to install HBO of 4-5 generations, that is, an injection system with direct injection of liquefied gas into the cylinder block.

If you are still thinking whether to switch to gas or not, we will give arguments for and against.

Advantages:

- sustainability;

- savings - for cars that wind up more than 2 thousand per month;

- mild engine operation (gas has a higher octane number, due to which there are fewer detonations that gradually destroy the engine).

Disadvantages:

- the high cost of equipment - for domestic cars 10-15 thousand, for foreign cars - 15-60 thousand rubles;

- termination of the machine warranty;

- re-registration and strict rules of operation;

- hard to find refill.

Installation of HBO

In fact, it is forbidden to install HBO on your own, for this there are appropriate workshops in which certified specialists are familiar with all the features and safety rules.

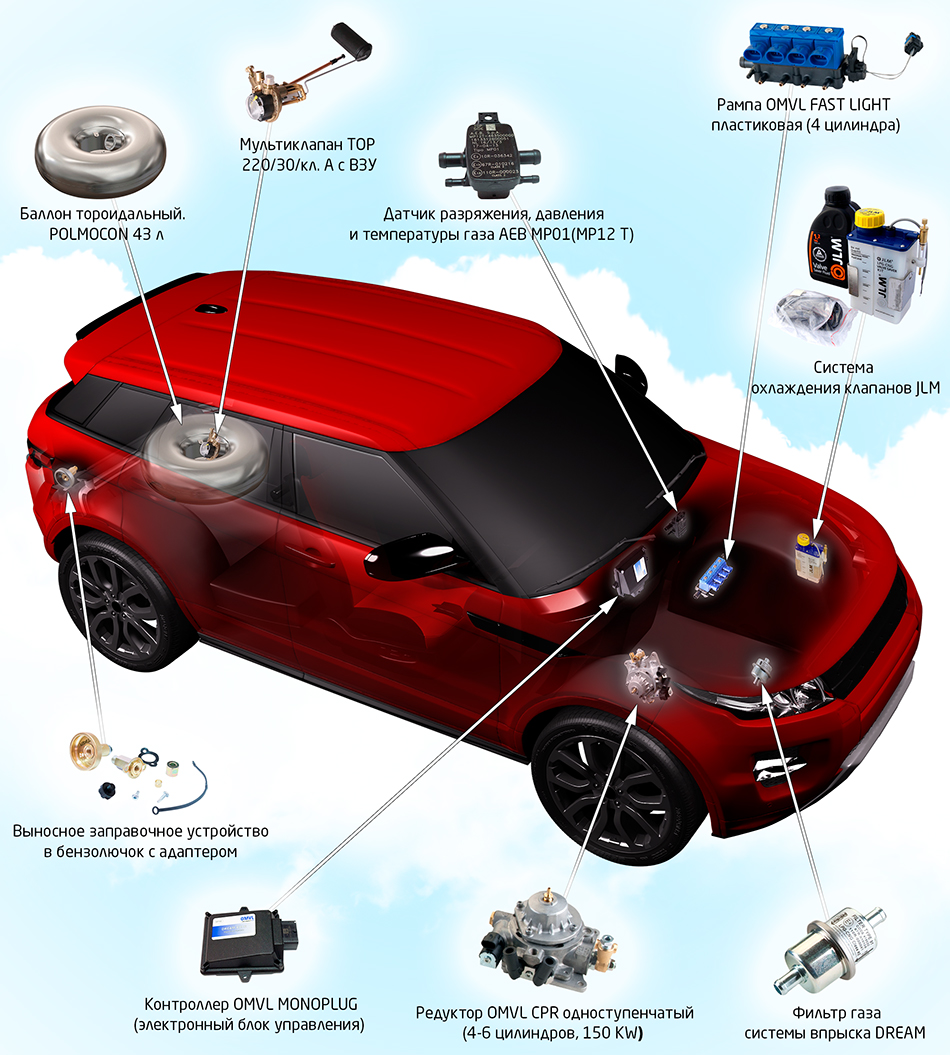

The main blocks of gas-cylinder equipment are:

- balloon;

- gearbox;

- Control block;

- nozzle block.

Connecting tubes and various communications are laid between these elements. The injector jets cut directly into the intake manifold. The master must monitor the tightness of the work. The nozzles from the jets are connected to the gas distributor, and a hose goes from it to the gearbox.

The gas reducer is designed to regulate the pressure in the gas system. The gearbox is connected to the engine cooling system. The absolute pressure sensor monitors the gas pressure, from which information is sent to the electronic control unit and, depending on the situation, certain commands are given to the gas valve.

Pipes are laid from the gas reducer to the cylinder itself. Cylinders can be both cylindrical and toroidal - in the form of a spare wheel, they take up less space, although you will have to look for a new place for the spare wheel. The cylinder is stronger than the metal from which the tank is made. If everything is installed correctly, then there should not be any smell of gas in the cabin.

Please note that there is a special compartment in the cylinder - a cutter, some unfortunate masters advise turning it off in order to save space. In no case do not agree, since the gas can expand at different temperatures up to 10-20 percent, and the cut-off just compensates for this space.

The tube from the gas reducer is connected to the cylinder reducer through which gas is supplied. Basically, that's all. Then the wires are laid, the control unit can be installed both under the hood and in the cabin. A button is also displayed in the cabin to switch between gasoline and gas. Switching is done thanks to a solenoid valve that cuts into the fuel line.

When accepting work, you need to check for leaks, smell of gas, how the engine works, how it switches from gas to gasoline and vice versa. If you did the installation in a center with a good reputation, then there is nothing to worry about, since everything is covered by the warranty. Private owners can use unsuitable tubes, for example, instead of thermoplastic hoses, ordinary water or fuel hoses are installed. The HBO must have a connection diagram, a calculation indicating the materials and equipment used.

If you follow all the recommendations given by experts, then switching to gas will really quickly pay off. And if the system is operated incorrectly, for example, starting the engine immediately on gas (you need to start and warm up the engine on gasoline), then you will have to fork out again.

Video about installing HBO

Loading…