The device and maintenance of the timing belt drive VAZ 2107

Content

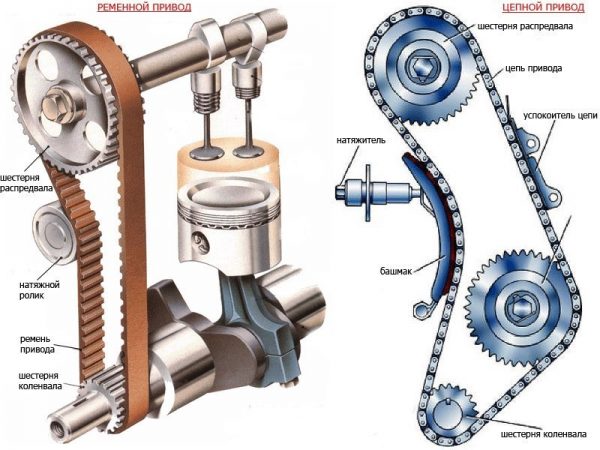

By installing a belt drive instead of a timing chain drive, VAZ engineers reduced the metal consumption of the engine and reduced its noise. At the same time, it became necessary to periodically replace the timing belt, which replaced a more reliable and durable two-row chain. This procedure does not take much time and is quite within the power of novice motorists who have decided to independently replace the timing belt on the domestic "classic" VAZ 2107.

The device and features of the timing belt drive of the VAZ 2107 car

The production of an 8-valve 1.3-liter VAZ power unit with a belt instead of a timing chain began in 1979. Initially, the VAZ 2105 ICE was produced with the index 21011 and was intended for the Zhiguli model of the same name, but later it was installed on other Togliatti cars - the VAZ 2107 sedan and the VAZ 2104 station wagon. The decision to install a belt drive instead of a timing chain drive was caused by the increased noise of the latter. And so, not the quietest engine began to make even more noise as the parts of the mechanism wore out. Modernization made the power unit more modern, but in return it required increased attention to the state of individual structural elements.

The functions that were previously performed by the chain were assigned to the belt drive. Thanks to her, it is set in motion:

- camshaft, through which the opening and closing moments of the valves are regulated. To transmit torque from the crankshaft, a toothed belt and a pair of the same pulleys are used. One cycle of operation of a four-stroke internal combustion engine is carried out for two revolutions of the crankshaft. Since in this case each valve needs to be opened only once, the camshaft speed must be 2 times lower. This is achieved by using toothed pulleys with a gear ratio of 2:1;

- auxiliary drive shaft (in garage slang “pig”), which transmits rotation to the oil pump and ignition distributor of carburetor engines, and also ensures the operation of the fuel pump.

Transverse teeth on the timing drive parts prevent slippage of the rubber structural element and ensure synchronous operation of the crank and gas distribution mechanisms. At the same time, during operation, the belt stretches, therefore, in order to prevent it from jumping on the pulley teeth, the drive was equipped with an automatic tension unit.

In order to prevent damage to the parts of the crank and gas distribution mechanisms when the belt breaks, the piston of the VAZ “belt” engine was equipped with special grooves, which drivers often call counterbores or scrapers. After the rotation of the crankshaft and camshaft is out of sync, the recesses in the piston prevent it from hitting the open valve. Thanks to this little trick, you can restore the performance of the power unit in less than an hour - just set the mechanism to the marks and replace the damaged part.

Interchangeability of timing belts VAZ

The prototype of the "belt" VAZ engine was the OHC power unit, which was installed on the passenger car FORD Pinto. Its timing mechanism drove a fiberglass-reinforced toothed belt that had 122 teeth. Due to the fact that the VAZ 2105 belt has exactly the same number of teeth and similar dimensions, individual owners of the domestic "classic" had an alternative to Russian-made belts. Of course, only a few had such an opportunity - in times of total shortage, they had to be content with less reliable products from the Balakovrezinotekhnika plant. Initially, only belts from BRT were installed on the engine, but a little later, more durable belts from Gates, which is the world leader in this market segment, began to be supplied to the conveyors of the Volzhsky plant.

Today, the owner of the VAZ 2107 has a huge selection of spare parts, including those for the timing belt drive. When buying, you must keep in mind that toothed belts with catalog number 2105–2105 (in another spelling 1006040) are suitable for the VAZ 21051006040 power unit. It has already been said above that rubber products manufactured by Gates and Bosch are considered among the best. The products of the giants of the world industry, such as Contitech, Kraft, Hanse, GoodYear and Wego, are of no less quality. Cheaper offers of the domestic Luzar cause the most criticism, despite the fact that they are not as widely represented in the distribution network as the market leaders.

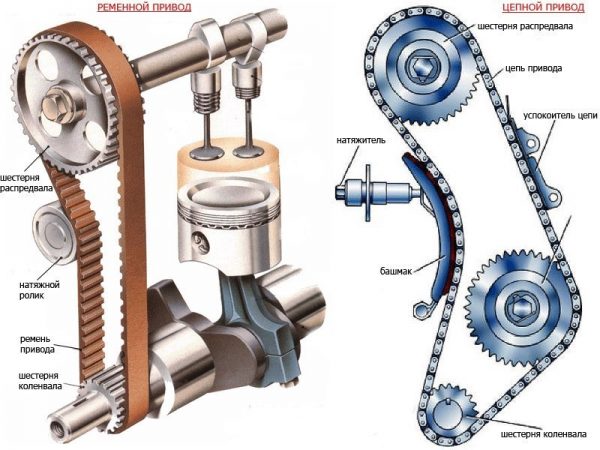

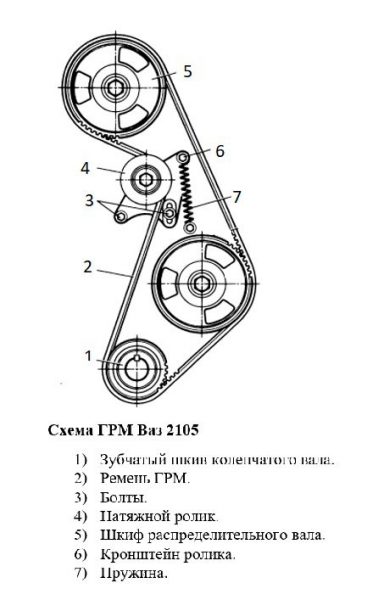

Tension mechanism

In order for the VAZ 2107 timing belt to be constantly tensioned, the simplest (one might even say primitive), but at the same time extremely efficient and reliable design is used. It is based on a figured metal plate (hereinafter - the tensioner lever), on which a smooth roller with a pressed rolling bearing is installed. The plate base has a hole and a slot for movable attachment of the lever to the cylinder block. The pressure on the belt is carried out thanks to a powerful steel spring, which at one end is connected to the bracket on the rotary plate, and at the other is rigidly attached to the bolt screwed into the cylinder block.

During operation, both the surface that the roller contacts with the rubber belt and the bearing wear out. For this reason, when replacing the timing belt, be sure to check the condition of the tensioner. If the roller is in good condition, then the bearing is washed, after which a fresh portion of grease is applied. At the slightest suspicion, the rotating structural element should be replaced. By the way, some drivers prefer to install a new roller at the same time as replacing the belt, without waiting until its bearing fails. I must say that today the cost of this part is from 400 to 600 rubles, so their actions can be considered quite appropriate.

Replacing the timing belt on the VAZ 2107

The manufacturer declares the need to carry out routine maintenance to replace the timing belt every 60 km. At the same time, reviews of real owners of “belt” VAZs with a classic layout speak of the need for such a replacement, sometimes and immediately after 30 thousand, arguing that cracks and breaks appear on the surface of the belt. And, I must say, such statements are not unfounded - it all depends on the quality. Russian-made rubber products do not differ in durability, so it is recommended to change them much earlier - after 40 thousand km. Otherwise, the risk of getting stuck on the road with an idle engine increases significantly. If we talk about the products of well-known foreign brands, then practice has shown that they easily work out the prescribed term and even after that they are in normal working condition. And yet, you should not wait until the timing drive fails. The belt should be replaced immediately in the following cases:

- upon reaching the threshold value of mileage set by the manufacturer (after 60000 km);

- if during the inspection cracks, delamination of rubber, tears and other defects are revealed;

- with excessive stretching;

- if a major or major engine overhaul was carried out.

Routine work is best done on a lift or from a viewing hole. Getting started with the replacement, you need to prepare:

- good quality timing belt;

- tensioner roller;

- screwdriver;

- crank;

- a set of open-end wrenches and heads (in particular, you will need tools for 10 mm, 13 mm, 17 mm and 30 mm).

In addition, it is necessary to have a metal brush and rags with which it will be possible to clean contaminated drive parts.

How to remove a worn belt

First of all, you need to disconnect and remove the battery from the car, and then dismantle the alternator drive belt. Using the “17” socket mounted on the extension, unscrew the nut that fixes the electrical unit and shift it towards the cylinder block. After the belt is loosened, it is removed from the pulleys with little or no effort.

The casing for protecting the drive of the gas distribution mechanism has three components, so it is dismantled in several stages. First, using the “10” key, remove the upper part of the casing. It is held in place by a bolt at the front of the valve cover. The middle and lower sections of the protective box are attached to the cylinder block - their dismantling also does not require much effort. Having gained access to the timing drive parts, you can begin to replace worn parts.

To remove the old belt, loosen the tensioner lever mounting bolt with a “13” socket wrench - it is located opposite the slot in its plate. Further, with the “30” key, the roller must be turned - this will loosen the tension of the toothed belt and allow it to be moved with the pulley, and then completely removed from the engine compartment. During replacement, try not to move the auxiliary drive shaft from its place, otherwise the ignition will be completely misadjusted.

Marks on the crankshaft

Synchronous rotation of both shafts will only be ensured when they are initially correctly installed. As a starting point, ICE designers choose the end of the compression stroke in the first cylinder. In this case, the piston must be at the so-called top dead center (TDC). On the first internal combustion engines, this moment was determined by a probe lowered into the combustion chamber - it made it possible to tactilely feel the location of the piston when turning the crankshaft. Today, setting the crankshaft in the correct position is much easier - manufacturers make a mark on its pulley and make marks on the cast-iron cylinder block.

During the replacement of the belt, the crankshaft is rotated until the mark on its pulley is set opposite the longest line on the cylinder block. By the way, this applies not only to the VAZ 2105 engines, but also to any other power unit of the VAZ "classic".

The installation of timing marks must be distinguished from work on adjusting the ignition timing. In the latter case, the crankshaft is installed so that the piston does not reach TDC a little. A few degrees of advance are needed for earlier ignition, which allows you to ignite the fuel mixture in a timely manner. Two other marks on the cylinder block allow you to correctly determine this moment. Aligning the mark on the pulley with the shortest line (it is in the middle) will give a lead of 5 degrees, while the extreme (medium length) will allow you to set the earliest ignition - 10 degrees before TDC.

Alignment of camshaft marks

The VAZ 2105 power unit with a belt drive differs from the 2101, 2103 and 2106 engines in that the mark on the camshaft gear is made by a thin risk, and not by a dot, as can be seen on the sprockets of the mentioned motors. The reciprocal dash is made in the form of a thin tide on the aluminum camshaft cover, next to the hole for attaching the protective casing of the belt drive. To set the marks one opposite the other, the camshaft is turned by holding the gear bolt with a key or rotating the pulley itself by hand.

Split gear camshaft

During operation, the timing belt made of rubber irreversibly stretches. To compensate for its weakening and avoid jumping on the pulley teeth, manufacturers recommend tensioning the belt at least once every 15 thousand kilometers. But a change in the linear characteristics of one of the drive elements has another negative consequence - it causes an angular displacement of the camshaft, as a result of which the valve timing shifts.

With a significant elongation, it is possible to set the mechanism according to the marks by turning the upper pulley by one tooth. In the case when, when the belt is shifted, the marks shift to the other side, you can use the split gear (pulley) of the camshaft. Its hub can be rotated relative to the crown, so that the position of the camshaft relative to the crankshaft can be changed without loosening the belt. In this case, the calibration step can be tenths of a degree.

You can make a split pulley with your own hands, however, for this you will have to buy another one of the same gear and use the help of a turner. You can take a closer look at the manufacturing process of the upgraded part in the video below.

Video: making a split timing gear VAZ 2105 with your own hands

Tension adjustment

Aligning the marks, carefully install the spare belt. After that, you can start adjusting its tension. And here the manufacturer has simplified life for mechanics as much as possible. It is enough to rotate the crankshaft a few turns clockwise for the steel spring to automatically create the desired tension force. Before the final fixation of the video, it is required to check the coincidence of the labels again. When they are displaced, the drive installation process is repeated, and after successful completion of the check, the tensioner is clamped with a “13” key.

All that's left is to check if the distributor rotor is in the 1st cylinder position and try to start the engine. If this was not possible, then the ignition distributor must be raised by turning its shaft so that the slider is opposite the contact of the 4th cylinder.

Video: features of replacing the timing belt

Watch this video on YouTube

As you can see, replacing a belt on a VAZ 2107 is not very difficult and can be done even by a novice driver. The power, reliability and economy of the car depend on the correct location of the marks and the correct tension of the belt, so you should show maximum attention and accuracy in work. Only in this case, you can count on the fact that the engine will not fail on a long journey and the car will always return to its native garage under its own power.