The device and principle of operation of the gearbox synchronizer

Content

The gearbox synchronizer is a mechanism designed to equalize the speed of the gearbox shaft and gear. Today almost all mechanical and robotic gearboxes are synchronized, i.e. equipped with this device. This important element in the gearbox makes shifting smooth and fast. From the article we will learn what a synchronizer is, what it is for and what the resource of its operation is; we will also understand the structure of the mechanism and get acquainted with the principle of its operation.

Synchronizer purpose

All transmissions of modern gearboxes of passenger cars, including reverse gear, are equipped with a synchronizer. Its purpose is as follows: ensuring the alignment of the speed of the shaft and gear, which is a prerequisite for shockless gear shifting.

The synchronizer not only ensures smooth gear changes, but also helps to reduce noise levels. Thanks to the element, the degree of physical wear of the mechanical parts of the box is reduced, which, in turn, affects the service life of the entire gearbox.

In addition, the synchronizer has simplified the principle of gear shifting, making it more convenient for the driver. Before the advent of this mechanism, gear shifting took place with the help of a double squeeze of the clutch and the transfer of the gearbox to neutral.

Synchronizer design

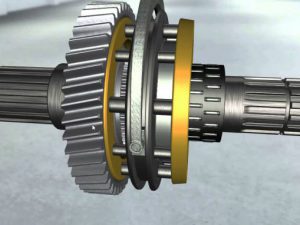

The synchronizer consists of the following elements:

- a hub with breadcrumbs;

- inclusion clutch;

- locking rings;

- gear with friction cone.

The base of the assembly is a hub with internal and external splines. With the help of the first, it connects to the gearbox shaft, moving along it in different directions. With the help of external splines, the hub is connected to the coupling.

The hub has three slots at 120 degrees to each other. The grooves contain spring-loaded crackers, which help to fix the clutch in the neutral position, that is, at the moment when the synchronizer is not working.

The clutch is used to provide a rigid connection between the gearbox shaft and the gear. It is located on the hub, and from the outside it is connected to the transmission fork. The synchronizer locking ring is necessary to synchronize the speed using frictional force, it prevents the clutch from closing until the shaft and gear have the same speed.

The inner part of the ring is cone-shaped. To increase the contact surface and reduce the effort when shifting gears, multi-cone synchronizers are used. In addition to single synchronizers, double synchronizers are also used.

The double synchronizer, in addition to the tapered ring that is attached to the gear, includes an inner ring and an outer ring. The tapered surface of the gear is no longer used here, and synchronization occurs through the use of rings.

The principle of operation of the gearbox synchronizer

In the off state, the clutch takes the middle position, and the gears rotate freely on the shaft. In this case, the transmission of torque does not occur. In the process of selecting a gear, the fork moves the clutch towards the gear, and the clutch, in turn, pushes the locking ring. The ring is pressed against the pinion cone and rotates, making further advancement of the clutch impossible.

Under the influence of the friction force, the gear and shaft speeds are synchronized. The clutch moves freely further and rigidly connects the gear and the gearbox shaft. The transmission of torque begins and the vehicle travels at the selected speed.

Despite the rather complex structure of the node, the synchronization algorithm lasts only a few fractions of a second.

Synchronizer resource

In case of any malfunctions associated with gear shifting, first of all, it is necessary to exclude problems with the clutch and only then check the synchronizer.

You can independently identify a node malfunction by the following signs:

- Transmission noise. This may indicate a curved locking ring or a worn out cone.

- Spontaneous shutdown of gears. This problem can be associated with the clutch, or with the fact that the gear has outlived its resource.

- Difficult inclusion of the transfer. This directly indicates that the synchronizer has become unusable.

Synchronizer repair is a very laborious process. It is better to simply replace the worn-out mechanism with a new one.

Observance of the following rules will help to extend the service life of the synchronizer and the gearbox as a whole:

- Avoid aggressive driving style, abrupt starts.

- Choose the right speed and gear.

- Timely carry out maintenance of the checkpoint.

- Timely change the oil intended specifically for this type of gearbox.

- Fully disengage the clutch before shifting gears.