Gear lever device

Content

The gear lever in a car with a manual transmission is a relatively simple and at the same time important element. The fact is that the driver constantly interacts with the specified lever in the process of driving.

At the same time, like any other device, the gear lever may fail, as a result of which the gear lever sags, there is a rattle, knock or creak when the lever is moved, etc., force is constantly applied to the lever, certain breakdowns may occur even in low mileage vehicles.

Next, we will look at how the “mechanical” gear lever works, what the gear lever is, as well as what are the most common malfunctions of this element and what you need to pay attention to in order to eliminate them.

Manual transmission lever: how it works, varieties and features

Thus, the usual gear lever handle (gear shift lever, gear lever) at first glance may seem to be an element that is extremely simple in terms of design. However, the overall design of the system is actually somewhat more complex. Let's figure it out.

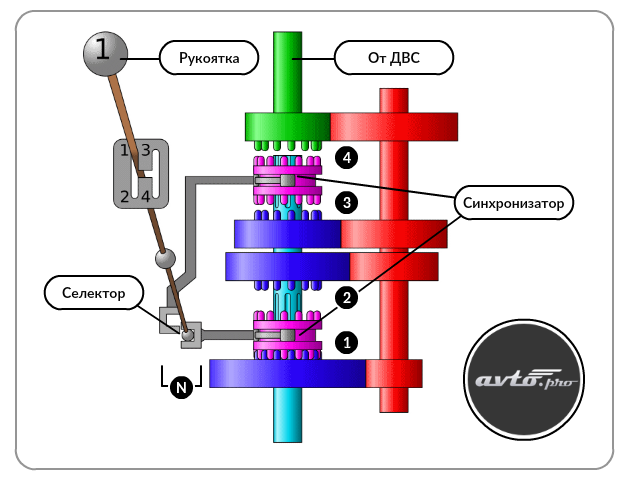

Firstly, in all manual transmissions (MT) it is necessary to manually act on the lever. In fact, through the lever, the driver transmits force to the mechanism for selecting and engaging / disengaging gears.

As a result, this allows you to select and engage the desired gear, determining the speed of the car, taking into account constantly changing conditions and loads. At the same time, it is simply impossible to drive a car with a manual transmission without a gear lever.

- The general principle of the lever is simple. If the gear is not engaged, the lever is in the neutral (center) position. In the neutral position, the lever is supported by springs.

Due to the possibility of movement in the longitudinal and transverse directions relative to the axis of the vehicle, it is possible to select and engage gears. The lateral movement allows you to select, and the longitudinal movement is responsible for turning on / off the speeds.

Briefly, the gear lever handle is connected to the synchronizer via a fork through a lever system. The gearbox synchronizer forcibly engages the necessary gears, ensuring that the selected gear stage (transmission) is engaged. As a rule, the gearshift pattern is usually displayed on the lever head (shift knob).

Also note that the gear lever can be installed on the floor (located near the central tunnel) and under the steering wheel. By the way, the location near the steering wheel is more convenient to use, however, for various reasons, it was the floor version that was most widely used.

The fact is that the gearshift lever under the steering wheel is characterized by reduced travel and worse clarity, there is a risk of not fully engaging the gear, the rods wear out faster, the rods stick, the rods, gears, etc. break.

It is noteworthy that the arrangement of levers (both the floor and the steering column) is almost the same. The difference lies in the length. So in practice, the longer the lever, the worse. If earlier the lever could be 20, 25 and even 30 cm long, now all levers in modern cars are as short as possible.

This allows you to get rid of the large lever travel. At the same time, the floor layout is more suitable for installing a short lever, which allows you to improve the quality of the mechanism without changing the design.

The main malfunctions of the gear lever and repair

As a rule, drivers are faced with the fact that during operation the lever can:

- it is difficult to move (it is necessary to make a lot of effort);

- the gear lever starts to freeze, which makes it difficult to work with it;

- there is a creak of the gear lever;

Please note that in the event of problems with the gear lever, the vehicle should be immediately stopped from operation and restored to working order.

The fact is that driving a car with a faulty gear lever is extremely dangerous, since in certain situations the inability to select in time, as well as turn on / off the gear, can cause an accident, etc.

As a rule, the lever stops working properly for two reasons:

- mechanical breakdowns or natural wear and tear of individual elements;

- malfunction due to too much force, damage to the lever, etc.

Checking the gearbox lever, as well as, in some cases, repairs can be carried out independently. First, the gear shift knob should normally move freely. Not allowed to eat. If the lever moves with obvious difficulty, the spherical washer or ball joint is likely to fail. These items need to be changed.

Another temporary measure is sometimes the application of a thick lubricant, which manages to neutralize the squeak of the gear lever. By the way, a creak also usually indicates the wear of the above elements. They added that if the gears themselves go astray, it will be necessary to check the spring, which can jump. To solve the problem, the spring simply snaps into place.

Repairing the gear lever itself often involves replacing failed elements. In this case, it will be necessary to remove the lever. To gain access to the plastic bushings and axle, you must first remove the switch boot.

To remove the lever, remove the plastic protective plate, and then release the hinge frame. Next, you need to take the jet thrust to the side, after which the entire lever is completely removed.

We also recommend reading the article on why the reverse gear does not turn on. In this article, you will learn about the main reasons why reverse gear does not engage.

You will also need to check how the axle is moving. If the movement of the shaft is not impeded in any way, it will be necessary to change the bushings (all replaceable elements must be lubricated with grease before installation).

To replace the spring, this element must be removed. To do this, the retaining ring is removed, as well as the hinge with the lever. If it is necessary to replace the ball joint, the spherical washer is carefully separated by fingers, after which the worn element can be removed. When installing a new support, the part must first be lubricated.

In the event that you need to replace the drive, you will need to find a clamp from under the car. It will be necessary to loosen the specified clamp, and then disconnect it from the hinges. Now you can unscrew the locknut and get traction. After laying a new thrust, the assembly is carried out in the reverse order.

After replacing all elements and lubrication, the lever should move smoothly and clearly, not hang, which allows you to conveniently and quickly select and engage gears. Also, if necessary, it is periodically required to lubricate and adjust the gear lever, hitch and other elements during the operation of the vehicle.

With the result that

As you can see, the gear lever is an important element, since the driver interacts with this part constantly and directly. Operation of the car is not allowed if there is excessive play in the lever, vibrations are noted, the gear lever is difficult to move, etc.

We also recommend reading an article on why gears shift poorly, reasons for difficult gear changes, etc. In this article, you will learn about the main problems resulting from poor gear shifting in a manual transmission. In other words, if the gear lever dangles, creaks, or “walks” poorly, it is necessary to disassemble, fix the malfunction, replace worn parts and lubricate the entire mechanism.

As a result, the driver can change gear quickly and accurately, which affects the comfort and safety of operating a car with a manual transmission.