Test drive in pursuit of a dream: from Wankel to HCCI engine

How the rotary engine helped the Japanese brand Mazda become what it is today

60 years after the creation of the first working prototype of the Wankel engine, 50 years after its launch by Mazda and the official announcement of the company that it has created a functional HCCI engine, this is an occasion to return to the history of this unique heat engine.

Mazda no longer hides the fact that the development of an engine that operates in a wide operating range in HCCI modes - or homogeneous mixing and compression ignition, has been successful, and intends to start series production of such an engine from 2019. No wonder Mazda can always surprise the automotive community. Even a cursory glance at the historical annals of the brand is enough to find the sources of this statement. Until recently, the Japanese company was the sole and zealous carrier of the Wankel idea and the first manufacturer of cars with engines operating on the Miller cycle (Mazda Xedos 9 from 1993 to 2003, and then Demio, known in Europe as Mazda 2).

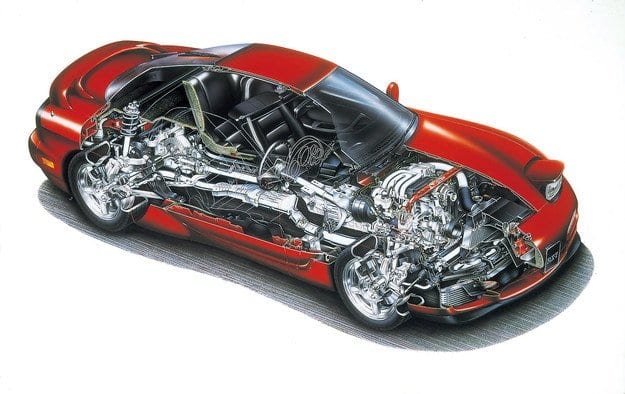

Worth mentioning here is the Comprex wave-compression diesel engine, cascaded, twin-jet and forced variable geometry for a gasoline engine (different versions of the Mazda RX-7), active rear axle steering systems 626 from the late 80s. years, the unique i-Stop start-stop system, in which starting is supported by the combustion process, and the energy recovery system using i-Eloop capacitors. Finally, note the fact that it is the only Japanese manufacturer to have won the 24 Hours of Le Mans - with a Wankel-powered car, of course! In terms of styling, models such as the Luce, the iconic Wankel Cosmo Sport, the RX-7 and RX-8, the MX-5 Roadster and the Mazda 6 speak volumes about the brand's uniqueness in this area. But that's not all - in recent years, Skyactiv engines have shown not only that the combustion engine still has a long way to go, but that Mazda can show it its own way.

We will tell a lot more about the developments of the company's engineers after our upcoming visit at the invitation of Mazda to Japan at the end of October. However, the reasons for this article are not the only ones that can be found in the subheading above. Because to understand the reasons why the creators of Mazda were able to create their HCCI engine, we may have to go back to the history of the company.

Rotary engine as the basis for Skyactiv-X

Ask an ultramarathoner who has completed a 160-kilometer route if there will be any problems completing a standard 42-kilometer marathon. Well, he might not run them for two hours, but he can definitely keep going for at least another 42 hours at a pretty decent pace. With this mindset, if your company is headquartered in Hiroshima, if for decades you have struggled with huge rotary engine piston rotation problems and solved hundreds of problems with lubrication or emissions, wave effects and turbocharging, or especially sickle chamber combustion processes with a variable block volume based on the Wankel, you can have a much more stable basis for building an HCCI engine. The official start of the Skyactiv project was given exactly ten years ago, in 2007 (the same year that Mercedes introduced the sophisticated HCCI Diesotto engine prototype), and at that time the Wankel-powered Mazda RX-8 was still in production. As you know, the engineers of the Japanese company are experimenting with HCCI operating modes precisely when developing prototypes of Skyactiv-R rotary engines. Probably, the HCCI project, called Mazda SPCCI (Spark Plug Conrolled Compression Ignition) or Skyactiv-X, involved engineers from both the rotary department and the gasoline and diesel engine department, because even in the development of the combustion process in Skyactiv-D we can recognize the handwriting of people involved in the development of the HCCI process. God knows when the evolution of Skyactiav engines turned into a homogenous agitation and self-ignition engine – Mazda engineers have long been known to be involved in this topic – but it probably happened when the Wankel engine was still alive.

Decades of manufacturing rotary cars, most of them all alone, may not bring Mazda a serious financial return, but it will also bring recognition of unwavering spirit, finding solutions to all sorts of problems, incredible perseverance and, as a result, the accumulation of vast and very invaluable experience. However, according to Kiyoshi Fujiwara, who is responsible for product planning at Mazda, each of the designers involved in the Skyactiv project carries the spirit of a Wankel engine, but turns into an opportunity to improve on a conventional engine. Or in non-traditional HCCI. “But the passion is the same. It is she who makes Skyactiv a reality. This real adventure has become the greatest joy in my life. It's true that every company makes cars to sell and make money,” explains Seita Kanai, Head of Development at Mazda, “but trust me, for us at Mazda, the fact that the cars we build is just as important. they originate in our hearts, and every time their construction becomes a romantic adventure for us. The main driving force behind this process is our passion. Being the best is my engineering romance.”

A young man's dream

Perhaps in the 60s, the engineers of the recently released first Mazda car found "an engineering novel of their own" in the Wankel engine. Because the rotary engine was born from the dream of a 17 year old German boy in 1919 and his name is Felix Wankel. Back then, born in 1902 in the Lahr region of Germany (where Otto, Daimler and Benz were born), he told his friends that his dream car had an engine that was half turbine, half piston. At that time, he did not yet have a basic knowledge of reciprocating internal combustion engines, but intuitively believed that his engine could perform four cycles of work - intake, compression, action and exhaust when the piston rotates. It is this intuition that will lead him for a long time to create a working rotary engine, which other designers have unsuccessfully tried countless times since the 16th century.

Wankel's father died during the First World War, after which the young man sold printed works and read a lot of technical literature. In 1924, at the age of 22, he founded a small laboratory for the development of a rotary engine, and in 1927 he made the first drawings of the "Die Drehkolbenmaschine" (rotary piston machine). In 1939, the ingenious Ministry of Aviation discovered a rational grain in the rotary engine and turned to Hitler, who personally ordered the release of Wankel, who was then in prison on the orders of the local Gauleiter, and to equip an experimental laboratory on Lake Constance. There he designed prototypes for BMW, Lillethal, DVL, Junkers and Daimler-Benz. However, the first experimental Wankel engine came too late to help the survival of the Third Reich. After the surrender of Germany, the French imprisoned Wankel - the same thing they had already done with Ferdinand Porsche. A year later, Felix was released and, for lack of a more productive occupation, began writing a book on rotary piston engines. He later founded the Technical Institute for Engineering Research and went on to develop rotary engines and compressors for industrial use. In 1951, an ambitious designer managed to convince the head of the NSU sports motorcycle department, Walter Frede, to cooperate. Wankel and NSU focused their efforts on a rotary engine with an apple-shaped (trochoid) chamber and an arched-walled triangular piston. In 1957, the first working prototype of the engine was built under the name DKN. This is the birth date of the Wankel engine.

60s: the promising future of the rotary engine

DKM shows that the rotary engine is not just a dream. A real practical Wankel engine in the fixed body form we know is the next KKM. NSU and Wankel jointly implemented early ideas related to piston sealing, spark plug positioning, hole filling, exhaust scavenging, lubrication, combustion processes, materials and manufacturing gaps. However, many problems remain...

This does not prevent NSU from officially announcing the creation of the engine of the future in 1959. More than 100 companies offer technical cooperation, including Mercedes, Rolls-Royce, GM, Alfa Romeo, Porsche, Citroen, MAN and a number of mechanical engineering companies buy licenses. Among them is Mazda, whose president Tsunei Matsuda sees great potential in the engine. In addition to concurrent consultations with NSU engineers, Mazda is setting up its own Wankel Engine Development Department, which initially includes 47 engineers.

The New York Herald Tribune declares the Wankel engine a revolutionary invention. At that time, NSU shares literally exploded - if in 1957 they traded for 124 German marks, then in 1960 they reached a cosmic 3000! In 1960, the first Wankel-powered car, the NSU Prinz III, was introduced. It was followed in September 1963 by the NSU Wankel Spider with a single chamber 500 cc engine, which won the German championship two years later. However, the sensation at the 3 Frankfurt Motor Show was the new NSU Ro 1968. The elegant sedan, designed by Klaus Lüthe, is avant-garde in every way, and its aerodynamic shapes (a flow factor of 80 in itself makes the car unique for its time) were made possible by a small-sized twin-rotor engine KKM 0,35. The transmission has a hydraulic clutch, four disc brakes, and the front part is located next to the transmission. The Ro 612 was so impressive for its time that it won Car of the Year in 80. The following year, Felix Wankel received his PhD from the Technical University of Munich and received the gold medal of the German Federation of Engineers, the most prestigious award for scientific and technical achievements in Germany.

(to follow)

Text: Georgy Kolev