Vacuum brake booster - device and principle of operation

Content

Precise control of vehicle deceleration is possible only if the amount of effort applied by the driver to the pedal is acceptable. But the powerful brakes of modern cars require the creation of significant pressures in the brake system. Therefore, the appearance of a brake booster has become a necessity, and the best solution is to use a vacuum in the engine intake manifold. This is how the vacuum brake booster (VUT) appeared, which is now used on almost all production cars.

Amplifier purpose

Requiring excess force from the driver looks illogical when there is such a powerful energy nearby as an internal combustion engine. Moreover, it is not even necessary to use mechanical, electrical or hydraulic drive types. There is a vacuum in the intake manifold due to the pumping action of the pistons, which can be applied by converting it into mechanical force.

The main function of the amplifier is to help the driver when braking. Frequent and strong pressure on the pedal is tiring, the accuracy of deceleration control is reduced. In the presence of a device that will, in parallel with a person, influence the amount of pressure in the brake system, both comfort and safety will increase. Brake systems without an amplifier are now impossible to meet on mass vehicles.

Amplification scheme

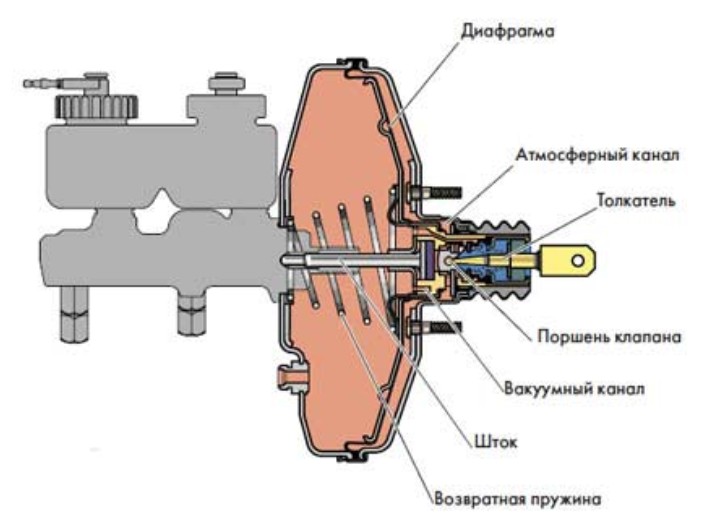

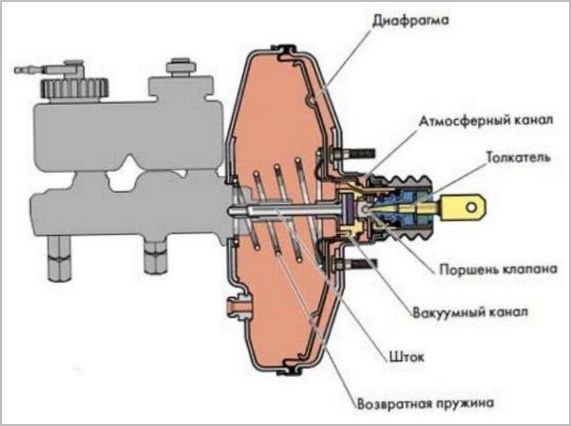

The amplifier block is located between the pedal assembly and the main brake cylinder (GTZ) of the hydraulic drive. It usually stands out for its significant size due to the need to use a large area membrane. The WUT includes:

- hermetic housing that allows you to change and maintain different pressures in its internal cavities;

- elastic diaphragm (membrane) separating the atmospheric and vacuum cavities of the housing;

- pedal stem;

- rod of the main brake cylinder;

- spring compressing the diaphragm;

- control valve;

- a vacuum extraction fitting from the intake manifold, to which a flexible hose is connected;

- atmospheric air filter.

When the pedal is not depressed, both cavities in the housing are at atmospheric pressure, the diaphragm is pressed by a return spring towards the pedal stem. When the stem is moved, that is, the pedal is pressed, the valve redistributes the pressure in such a way that the cavity behind the membrane communicates with the intake manifold, and the atmospheric level is maintained on the opposite side.

If the car is equipped with a diesel engine that does not have a throttle valve, and the vacuum in the manifold is minimal, then the vacuum is generated by a special pump driven by the engine or its own electric motor. Despite the complexity of the design, in general, this approach justifies itself.

The pressure difference between the outer and inner sides of the diaphragm, due to its large area, creates a tangible additional force applied to the GTZ rod. It folds with the force of the driver's leg, creating a reinforcement effect. The valve regulates the amount of force, preventing pressure surges and ensuring smooth operation of the brakes. The exchange of air between the chambers and the atmosphere is carried out through a filter that prevents clogging of the internal cavities. A non-return valve is installed in the vacuum supply fitting, which does not allow monitoring pressure changes in the intake manifold.

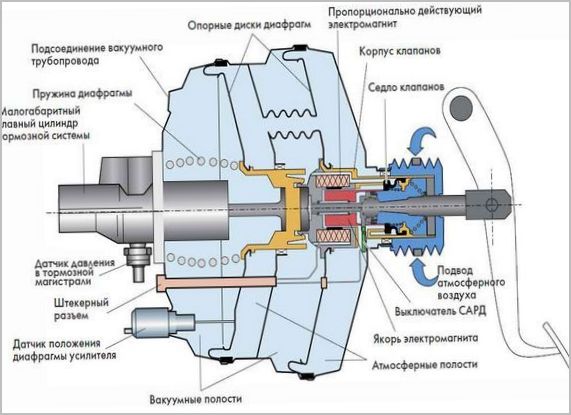

Introduction of electronics into the amplifier

The general trend has been the appearance in the car of numerous electronic assistants that remove part of the requirements from the driver. This also applied to vacuum amplifiers.

If it is necessary to brake urgently, not all drivers act on the pedal with the desired intensity. An emergency braking assistance system was developed, the sensor of which is built into the VUT structure. It measures the speed of movement of the rod, and as soon as its value exceeds the threshold value, an additional solenoid is turned on, fully mobilizing the capabilities of the membrane, opening the control valve to the maximum.

Sometimes fully automatic control of the VUT is also used. At the command of the stabilization systems, the vacuum valve opens, even if the pedal is not pressed at all, and the booster is included in the operation of other brake mechanisms under the control of electronic assistants.

Possible malfunctions and adjustment

There are problems in increasing the force on the brake pedal. If this happens, then you should check the VUT in a simple way - press the pedal several times with the engine stopped, then, holding the brake pressed, start the engine. The pedal should move a certain distance due to the vacuum that has appeared.

Breakdowns are usually caused by a leaky diaphragm or control valve failure. The design is non-separable, VUT is replaced as an assembly.

Adjustment consists in setting a certain value of the free stroke of the rod. So that the valve turns on in a timely manner, and at the same time there is no spontaneous braking. But in practice, there is no need for this, all amplifiers come from the manufacturer already correctly adjusted.