Driving axles of MAZ trucks

Content

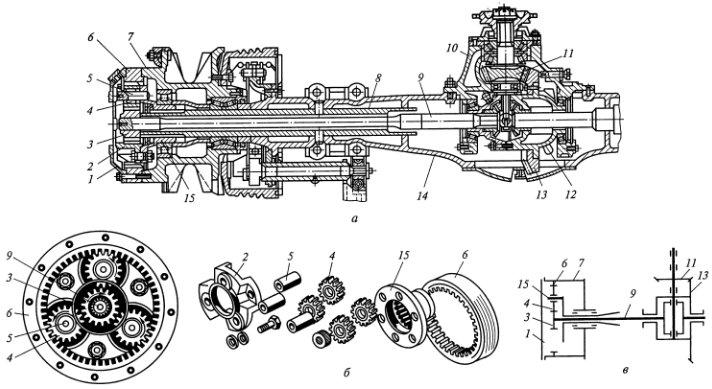

MAZ vehicles can have two drive axles (rear and axle shafts with a through axle) or only one - rear. The design of the drive axle includes a central bevel gear connected to the planetary gears in the wheel hubs. Bridge beams have a variable section and consist of two stamped halves connected by welding.

The principle of operation of the drive axle

The kinematic diagram of the drive axle is as follows: the torque supplied to the central gearbox is divided into gear wheels. Meanwhile, in wheel reduction gears, different gear ratios can be achieved by changing the number of teeth on the wheel reduction gears. That allows you to put the same size rear axles on various modifications of the MAZ.

Depending on the expected operating conditions of the MAZ model, the modification of the gearbox, the size of the tires of the vehicles, the rear axles of the MAZ are manufactured with three different overall gear ratios. As for the middle axle MAZ, its beam, drive wheels and cross-axle differential are made by analogy with the details of the rear axle. It is easy to buy or pick up spare parts for a medium-shaft MAZ if you refer to the catalog of original spare parts.

Drive axle maintenance

When operating a MAZ vehicle, it must be remembered that the drive axles need maintenance and adjustment from time to time. When driving every 50-000 km, be sure to visit a service station to inspect and, if necessary, adjust the axial play of the bearings of the drive gear of the central gearbox. It will be difficult for inexperienced motorists to make this adjustment on their own, because. First, remove the propeller shaft and tighten the flange nut to the appropriate torque. Similarly, the adjustment of the gearbox of the central axis is carried out. In addition to adjusting the clearance in the bearings, it is important to change the lubricant in a timely manner, maintain the required amount of lubricant, and monitor the sounds of the shafts.

Troubleshooting drive axles

The rear gearbox maz represents the maximum load. Even the presence of an average driving axle does not reduce it. Malfunctions of drive axles, causes and methods of repair will be considered in more detail.

Fault: bridge overheating

Reason 1: Lack or, conversely, excess oil in the crankcase. Bring the oil to the normal volume in the crankcases of the gearbox (central and wheel).

Cause 2: Gears not adjusted correctly. Requires gear adjustment.

Cause 3: Too much bearing preload. The bearing tension needs to be adjusted.

Error: increased bridge noise

Cause 1: Bevel gear engagement failure. Adjustment required.

Cause 2: Worn or misaligned tapered bearings. It is necessary to check, if necessary, adjust the tightness, replace the bearings.

Cause 3: Gear wear, teeth pitting. It is necessary to replace worn gears and adjust their meshing.

Bug: Increased bridge noise when cornering

Cause: Differential failure. It is necessary to disassemble, repair and adjust the differential.

Problem: Gear noise

Cause 1: Insufficient oil level in the wheel reduction gear. Pour oil into the gearbox housing to the correct level.

Cause 2: Technical oil not suitable for gears is filled. Thoroughly wash the hubs and drive parts, fill with the appropriate oil.

Cause 3: Worn gears, pinion shafts or bearings. Replace worn parts.

Fault: Oil leaking through seals

Cause: Worn seals (glands). Replace worn seals. If there is oil leakage from the hub drain hole, replace the hub seal.

Keep track of the technical condition of your "iron horse", and he will thank you for a long and reliable service.