Crankcase ventilation - why is it needed?

Content

Reducing the emission of various harmful compounds into the atmosphere from the crankcase of the internal combustion engine is carried out by means of a special crankcase ventilation system.

Features of the engine crankcase ventilation system

Exhaust gases can enter the crankcase from the combustion chambers during the operation of an automobile engine. In addition, the presence of water, fuel and oil vapors is often noted in the crankcase. All these substances are called crankcase gases.

Their excessive accumulation is fraught with the destruction of those parts of the internal combustion engine that are made of metal. This is due to a decrease in the quality of the composition and performance of engine oil.

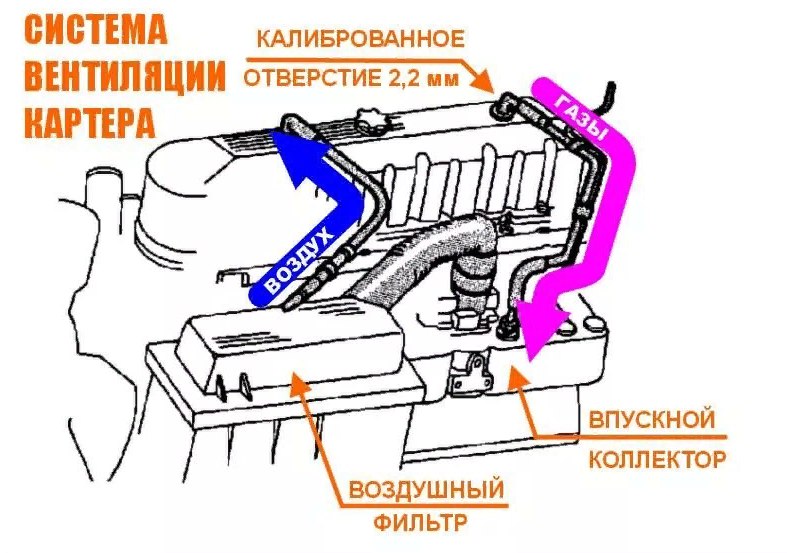

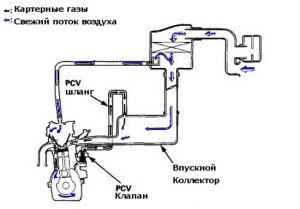

The ventilation system we are interested in is intended to prevent the described negative phenomena. On modern vehicles, it is forced. The principle of its work is quite simple. It is based on the application of a vacuum formed in the intake manifold. When the specified vacuum appears, the following phenomena are observed in the system:

- removal of gases from the crankcase;

- purification from oil of these gases;

- movement through the air nozzles of the connections that have been cleaned to the collector;

- subsequent combustion of gases in the combustion chamber when mixed with air.

Design of the crankcase ventilation system

On different motors, which are produced by different manufacturers, the described system is characterized by its own design. At the same time, in each of these systems, in any case, there are several common components. These include:

- ventilation valve;

- oil separator;

- air pipes.

The valve is necessary to adjust the pressure of the gases that enter the intake manifold. If their vacuum is significant, the valve switches to closed mode, if insignificant - to open.

The oil separator, which the system has, reduces the phenomenon of soot formation in the combustion chamber due to the fact that it does not allow oil vapor to penetrate into it. Oil can be separated from gases in two ways:

- cyclic;

- labyrinthine.

In the first case, they speak of a centrifugal type oil separator. Such a system assumes that gases rotate in it, and this leads to oil settling on the walls of the device, and then draining into the crankcase. But the labyrinth mechanism works differently. In it, crankcase gases slow down their movement, due to which oil is deposited.

Internal combustion engines of today are usually equipped with combined oil separation systems. In them, the labyrinth device is mounted after the cyclic one. This ensures the absence of gas turbulence. Such a system at the moment, without exaggeration, is ideal.

Crankcase ventilation connection

On Solex carburetors, in addition, there is always a ventilation fitting (without it, the ventilation system does not work). The fitting is very important for the stable functioning of the crankcase ventilation of the engine, and here's why. Sometimes high-quality removal of gases does not occur due to the fact that the vacuum in the air filter is small. And then, in order to increase the efficiency of the system, an additional branch is introduced into it (usually it is called a small branch).

It just connects the throttle zone with a fitting, through which crankcase gases are removed from the internal combustion engine. Such an additional branch has a very small diameter - no more than a few millimeters. The fitting itself is located in the lower zone of the carburetor, namely, under the acceleration pump in the throttle area. A special hose is pulled onto the fitting, which performs an exhaust function.

Watch this video on YouTube

• power drop;

• increased fuel consumption;

• rapid and severe contamination of the throttle valve and idle speed controller;

• oil in the air filter.

Most of these signs can be attributed to other malfunctions, for example, malfunctions in the ignition system. Therefore, when diagnosing, it is recommended to check the crankcase ventilation system. As the power plant wears out, more and more soot, soot and other contaminants enter the crankcase. Over time, they are deposited on the walls of channels and pipes.

A faulty crankcase ventilation system can cause a lot of problems in the winter. Quarry gases always contain particles of water, getting into the ventilation system, they can condense into steam and accumulate anywhere. When the engine cools, the water naturally freezes and turns into ice, blocking the channels. In advanced cases, the channels and pipes are clogged so much that the pressure in the crankcase rises and squeezes out the dipstick, while the entire engine compartment is splashed with oil. This can happen on a motor with any mileage, with the exception of engines with additional crankcase heating.