Fuel injection in petrol engines. Advantages, disadvantages and possible problems

The type of injection system determines engine parameters and operating costs. It affects the dynamics, fuel consumption, exhaust emissions and maintenance costs of the car.

The type of injection system determines engine parameters and operating costs. It affects the dynamics, fuel consumption, exhaust emissions and maintenance costs of the car.

The history of the practical application of gasoline injection in an internal combustion engine in transport dates back to the period before the First World War. Even then, aviation was urgently looking for new solutions that could improve the efficiency of engines and overcome problems with power in various positions of the aircraft. Fuel injection, which first appeared in the 8 French V1903 aircraft engine, proved useful. It wasn't until 1930 that the fuel-injected Mercedes 1951 SL debuted, widely regarded as a forerunner in the field. However, in the sports version, it was the first car with direct petrol injection.

The history of the practical application of gasoline injection in an internal combustion engine in transport dates back to the period before the First World War. Even then, aviation was urgently looking for new solutions that could improve the efficiency of engines and overcome problems with power in various positions of the aircraft. Fuel injection, which first appeared in the 8 French V1903 aircraft engine, proved useful. It wasn't until 1930 that the fuel-injected Mercedes 1951 SL debuted, widely regarded as a forerunner in the field. However, in the sports version, it was the first car with direct petrol injection.

Electronic fuel injection was first used in the 300 in a 1958 Chrysler engine. Multipoint petrol injection began to appear on cars in the 1981s, but it was mostly used in luxury models. High-pressure electric pumps were already in use to ensure proper pressure, but control was still the responsibility of mechanics, who only faded into oblivion in 600 with the end of Mercedes production. Injection systems were still expensive and did not change to cheap and popular cars. But when it became necessary in the XNUMXs to install catalytic converters on all cars, regardless of their class, a cheaper type of injection had to be developed.

The presence of a catalyst required more precise control of the composition of the mixture than carburetors could provide. Thus was created single-point injection, a meager version of "multi-point", but sufficient for the needs of cheap cars. Since the late nineties, it began to disappear from the market, replaced by multi-point injectors, which are currently the most popular fuel system in automotive engines. In 1996, direct fuel injection made its standard debut on the Mitsubishi Carisma. The new technology needed serious improvement and at first found few followers.

However, in the face of increasingly stringent exhaust gas standards, which from the very beginning had a strong influence on the progress in automotive fuel systems, designers eventually had to move to gasoline direct injection. In the latest solutions, so far few in number, they combine two types of gasoline injection - indirect multi-point and direct.

However, in the face of increasingly stringent exhaust gas standards, which from the very beginning had a strong influence on the progress in automotive fuel systems, designers eventually had to move to gasoline direct injection. In the latest solutions, so far few in number, they combine two types of gasoline injection - indirect multi-point and direct.

Indirect Single Point Injection

In single point injection systems, the engine is powered by a single injector. It is installed at the inlet of the intake manifold. Fuel is supplied under pressure of about 1 bar. The atomized fuel mixes with air in front of the intake ports of the channels leading to the individual cylinders.

The fuel-air mixture is sucked into the channels without precise dosing of the mixture for each cylinder. Due to differences in the length of the channels and the quality of their finishes, the power supply to the cylinders is uneven. But there are also benefits. Since the path of the mixture of fuel with air from the nozzle to the combustion chamber is long, the fuel can evaporate well when the engine warms up properly. In cold weather, the fuel does not evaporate, the bristles condense on the collector walls and partially go into the combustion chamber in the form of drops. In this form, it cannot completely burn out on the working cycle, which leads to low engine efficiency in the warm-up phase.

The consequence of this is increased fuel consumption and high toxicity of exhaust gases. Single point injection is simple and cheap, does not require many parts, complex nozzles and advanced control systems. Low production costs result in a lower vehicle price, and repairs with single point injection are easy. This type of injection is not used in modern passenger car engines. It can only be found in models with a backward design, although produced outside of Europe. One example is the Iranian Samand.

privileges

– Simple design

– Low production and maintenance costs

– Low toxicity of exhaust gases when the engine is hot

defects

– Low fuel dosing accuracy

– Relatively high fuel consumption

– High toxicity of exhaust gases in the warm-up phase of the engine

– Poor performance in terms of engine dynamics

Indirect multipoint injection

Indirect multipoint injection

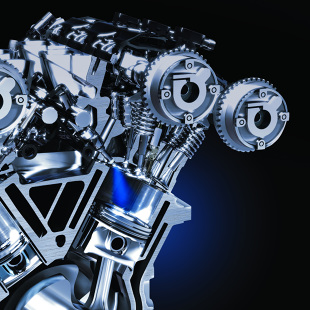

An extension of single-point indirect injection is multi-point indirect injection with an injector in each intake port. Fuel is delivered after the throttle, just before the intake valve. The injectors are closer to the cylinders, but the air/fuel mixture path is still long enough for the fuel to vaporize on a hot engine. On the other hand, the heating phase has less tendency to condense on the walls of the intake port, since the distance between the nozzle and the cylinder is shorter. In multi-point systems, fuel is supplied at a pressure of 2 to 4 bar.

A separate injector for each cylinder gives designers completely new possibilities in terms of increasing engine dynamics, reducing fuel consumption and reducing exhaust emissions. Initially, no advanced control systems were used, and all nozzles dispensed fuel at the same time. This solution was not optimal, since the injection moment did not occur in every cylinder at the most advantageous moment (when it hit the closed intake valve). Only the development of electronics made it possible to build more advanced control systems, thanks to which the injection began to work more accurately.

Initially, the nozzles opened in pairs, then a sequential fuel injection system was developed, in which each nozzle opens separately, at the optimum moment for a given cylinder. This solution allows you to accurately select the dose of fuel for each stroke. A serial multi-point system is much more complex than a single-point system, more expensive to manufacture and more expensive to maintain. However, it allows you to significantly increase the efficiency of the engine with less fuel consumption and less toxicity of exhaust gases.

privileges

– High fuel dosing accuracy

– Low fuel consumption

– Many possibilities in terms of engine dynamics

– Low toxicity of exhaust gases

defects

- Significant design complexity

– Relatively high production and maintenance costs

Direct injection

Direct injection

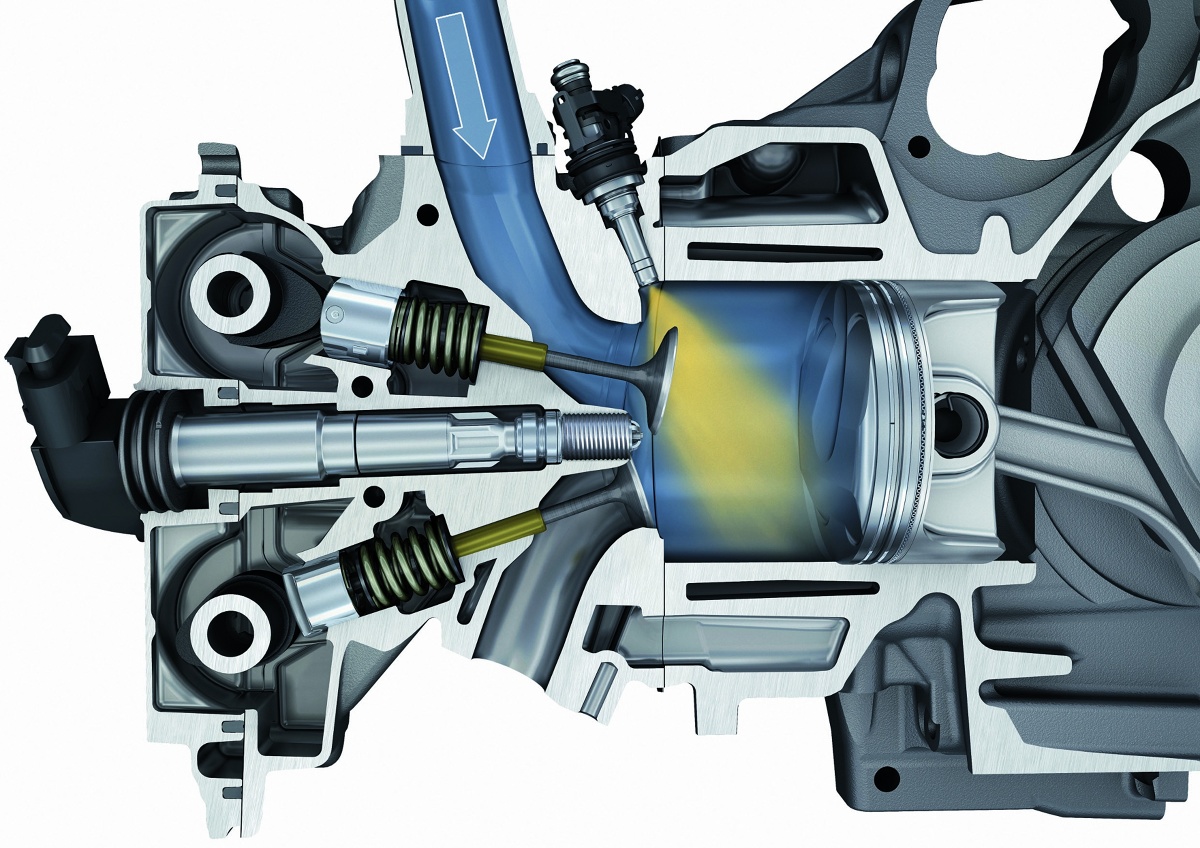

In this solution, the injector is installed in the cylinder and injects fuel directly into the combustion chamber. On the one hand, this is very beneficial, as it allows you to very quickly replace the fuel-air charge above the piston. In addition, the relatively cold fuel cools the piston crown and cylinder walls well, so it is possible to increase the compression ratio and obtain higher engine efficiency without fear of adverse combustion knock.

Direct injection engines are designed to burn very lean air/fuel mixtures at low engine loads to achieve extremely low fuel consumption. However, it turned out that this causes problems with an excess of nitrogen oxides in the exhaust gases, to eliminate which it is necessary to install appropriate cleaning systems. Designers deal with nitrogen oxides in two ways: by adding boost and reducing the size, or by installing a complex system of two-phase nozzles. Practice also shows that with direct fuel injection, the unfavorable phenomenon of carbon deposits in the intake ducts of the cylinders and on the intake valve stems (decrease in engine dynamics, increase in fuel consumption).

This is because both the intake ports and the intake valves are not flushed with the air/fuel mixture as with indirect injection. Therefore, they are not washed away by fine oil particles entering the suction system from the crankcase ventilation system. Oil impurities harden under the influence of temperature, creating an increasingly thick layer of unwanted sludge.

privileges

– Very high fuel dosing accuracy

– Possibility of burning lean mixtures

– Very good engine dynamics with low fuel consumption

defects

- Extremely complex design

– Very high production and maintenance costs

– Problems with excess nitrogen oxides in exhaust gases

- Carbon deposits in the intake system

Dual injection - direct and indirect

Dual injection - direct and indirect

Mixed injection system design takes advantage of both indirect and direct injection. Direct injection works when the engine is cold. The fuel/air mixture flows directly over the piston and condensation is excluded. When the engine is warm and running under light load (constant speed driving, smooth acceleration), direct injection stops working and multi-point indirect injection takes over its role. Fuel evaporates better, very expensive direct injection system injectors do not work and do not wear out, intake valves are washed by the fuel-air mixture, so deposits do not form on them. At high engine loads (strong accelerations, fast driving), direct injection is switched on again, which ensures very fast filling of the cylinders.

privileges

– Very precise fuel dosage

– Optimal engine delivery in all conditions

– Very good engine dynamics with low fuel consumption

– No carbon deposits in the intake system

defects

- Huge design complexity

– Extremely high production and maintenance costs