Everything you need to know about electric vehicle batteries

Although there are many types of batteries, lithium-ion batteries are the most widely used for electric vehicles. It is truly the dominant technology in the market, especially in terms of performance and durability.

Battery production is independent of vehicle assembly: some vehicles are assembled in France, but their batteries are produced much further, as in the case of the Renault Zoé.

In this article, La Belle Batterie gives you clues to understanding how batteries for electric vehicles are produced and by whom.

Battery manufacturers

Carmakers themselves do not manufacture batteries for their electric vehicles; they work with large partner companies, which are mainly located in Asia.

Different models are available depending on the manufacturer:

- Partnership with a specialized industrialist

Manufacturers such as Renault, BMW, PSA and even Kia are turning to third-party companies that make cells or even modules for their batteries. However, these car manufacturers prefer to assemble the batteries themselves in their own factories: they only import the cells.

The main manufacturer partners are LG Chem, Panasonic and Samsung SDI... These are Asian companies that have recently opened factories in Europe to close the geographic gap: LG Chem in Poland and Samsung SDI and SK Innovation in Hungary. This makes it possible to bring the place of production of cells closer to the places of assembly and manufacture of batteries.

For example, for Renault Zoé, its battery cells are manufactured in Poland at the LG Chem plant, while the battery is manufactured and assembled in France at Renault's plant in Flains.

This also applies to the Volkswagen ID.3 and e-Golf, for which the cells are supplied by LG Chem, but the batteries are made in Germany.

- 100% own production

Some manufacturers choose to manufacture their batteries from A to Z, from cell fabrication to battery assembly. This is the case with Nissan, whose Leaf cells are manufactured by Nissan AESC. (AESC: Automotive Energy Supply Corporation, a joint venture between Nissan and NEC). Cells and modules are produced and batteries are assembled at the British plant in Sunderland.

- Domestic production, but at multiple sites

Among manufacturers who prefer to manufacture their batteries in-house, some choose a split process from different factories. Tesla, for example, has its own battery factory: the Gigafactory, located in Nevada, USA. Cells and battery modules designed by Tesla and Panasonic are manufactured in this plant. Tesla Model 3 batteries are also manufactured and assembled, resulting in a single, streamlined process.

Tesla electric vehicles are then assembled at a factory in Fremont, California.

How are batteries made?

The production of batteries for electric vehicles takes place in several stages. The first one is extraction of raw materials necessary for the manufacture of elements: lithium, nickel, cobalt, aluminum or manganese... Subsequently, manufacturers are responsible for produce battery cells and their components: anode, cathode and electrolyte.

After this step the battery can be produced and then assembled. Last step - assemble an electric car with a built-in battery.

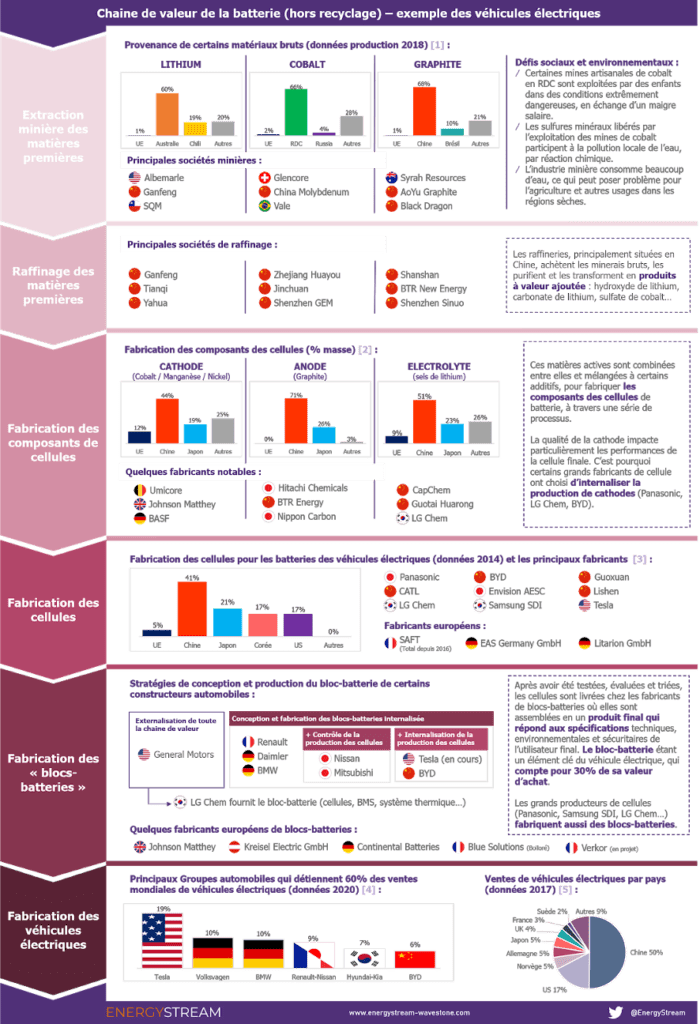

Below you will find an infographic released by Energy Stream detailing all the stages of battery production for an electric vehicle, as well as identifying the main manufacturers and manufacturers for each stage.

This infographic also deals with the social and environmental issues associated with the production of batteries, and in particular with the first stage, which is the extraction of raw materials.

Indeed, in the life cycle of an electric vehicle, it is the production phase that has the greatest impact on the environment. Some of you may be wondering: Is the electric vehicle more polluting than its thermal counterpart? Feel free to refer to our article, you will find some answers.

Battery Innovation

Today, car manufacturers are more aware of electric vehicles and their batteries, which has allowed them to develop many technologies. Thus, batteries are more efficient and can dramatically increase the autonomy of electric vehicles.

Over the past decade, tremendous progress has been made and companies continue to research to further improve these battery technologies.

When we talk about battery innovation, we definitely think of Tesla, a pioneer in the field of electric vehicles.

The company has really developed an integer na new generation of cells called "4680", larger and more efficient than the Tesla Model 3 / X. Elon Musk does not want to be satisfied with what has already been achieved, as Tesla plans to develop batteries that pollute the environment, in particular, by using nickel and silicon instead of cobalt and lithium.

Various companies around the world are currently developing new batteries for electric vehicles, either improving lithium-ion technology or offering other substitutes that do not require heavy metals. Researchers are thinking in particular about batteries in lithium-air, lithium-sulfur or graphene.