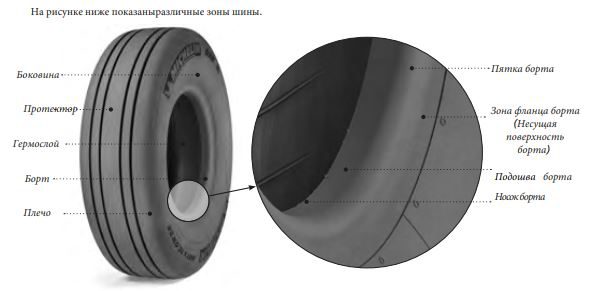

All about aircraft tires

It is a tire that concentrates all technological tasks (except for one: side grip)

20 bar pressure, 340 km / h, temperature differential from -50 to 200 ° C, over 25 tons of load ...

After seeing how the GP tire is the pinnacle of motorcycle tire, here's an additional insight into the amazing world of tires! And this illumination brings us aircraft tirewhich is definitely the bus that concentrates the most technological problems. But let's put some contextual elements before getting to the heart of the matter.

4 large families and the technological paradox

The world of aviation is divided into four main families: Civil aviation refers to small private jets such as the Cessna. Regional aviation concerns medium-sized aircraft with a capacity of 20 to 149 seats, which travel about several hundred kilometers, as well as business jets. Commercial aviation has the ability to operate transcontinental flights. As for the military aviation, it is aptly named.

However, the aircraft tire suffers from a great paradox. It is claimed to be hyper-tech, but in three of the four business families (civil, regional, and military aviation), aviation rubber is still mostly diagonally tech-savvy. Yes, diagonal, not radial like our good old front linkage or, more recently, the good Honda CB 750 K0! This is why in civil aviation, for example, there are many brands that are capable of offering tires.

The reason is simple: in aviation, component approval standards are extremely stringent and complex. Thus, when a part is approved on the aircraft, it is validated for the life of the aircraft. Homoloding another part would be extremely expensive, and since the lifespan of the aircraft is at least 3 decades, sometimes longer, technological steps are slower than in other areas. Thus, each new generation of aircraft accelerates the rate of market radialization.

This is more difficult in commercial aviation, where the standards are even stricter. Therefore, the tires are radial, and only two players master this technology and share the market: Michelin and Bridgestone. Welcome to lerepairedespilotesdavion.com !!

The (hard) life of a Boeing or Airbus aircraft tire

Imagine that you are an airplane bus (no reason, Hindus dream of reincarnating as a cow or lotus flower). Thus, you are an aircraft tire fitted on, say, an Airbus A340 or Boeing 777, in their long-range version. You are quietly on the tarmac of Terminal 2F in Roissy. The corridors have been cleared. Smells fresh. The crew is coming. Hmm, the hostesses are wonderful today! The bins are open, the luggage comes in, the passengers leave, they are happy to go on vacation. Food trays loaded: beef or chicken?

On the other hand, you feel a little heavy, as if squeezed in your shoulders. I must say that almost 200 liters of kerosene have just been thrown into your wings. All inclusive, the plane can weigh nearly 000 tons. Obviously, you are not alone to carry all this mass: the Airbus A380 has 340 tires, the A14, 380. However, although your dimensions are comparable to the dimensions of a truck tire, you must carry a load of 22 tons, while a truck tire just carries an average of 27 tons.

Everyone is ready to start. Slide activation. Checking the opposite door. It will hurt you there. Because to leave the landing, the heavily loaded plane will spin on its own to get out of its parking lot. The rubber for the tire will undergo a shearing effect, a kind of tearing at the contact area. Ouch!

What is called "taxi" time: a taxi between the gate and the runway. This trip is performed at a reduced speed, but as airports get larger, it can be done for more than a few kilometers. Here, this is also not good news for you: the tire is heavily loaded, it rolls for a long time and heats up. It is even worse at a large airport with high temperatures (eg Johannesburg); better in a small airport in northern countries (eg Ivalo).

In front of the track: gas! In about 45 seconds, the pilot will reach his takeoff speed (250 to 320 km / h depending on the strength of the aircraft and the wind). This is a last-ditch effort for an aviation tire: speed limits are added to the load and then the tire can briefly heat up to over 250 ° C. Once in the air, the tire enters the cavity for several hours. Take a nap, grief? That's what, except it's -50 ° C! Under these conditions, many materials will become as hard as wood and brittle as glass: not an aircraft tire, which will have to quickly restore all its qualities.

In addition, the runway is visible. Get off the train. The plane touches the ground smoothly at a speed of 240 km / h. For the tire, this is happiness, because there is almost no kerosene, so everything weighs a hundred tons less, and therefore during these efforts it will only rise to a temperature of 120 ° C! On the other hand, carbon discs heat up a little, the 8 tracks of which generate more than 1200 ° C of heat. It's getting hot! A few more short kilometers of taxi and airplane bus will be able to cool down and rest on the asphalt, waiting for a new cycle ... scheduled in just a few hours!

NZG or RRR, advanced technology

July 25, 2000: Tragedy at Roissy when Concorde of Air France Flight 4590 to New York crashed 90 seconds after takeoff. One of the tires was damaged by debris left on the runway; a piece of tire comes off, touches one of the tanks and causes an explosion.

In the world of aeronautics, this is horror. Manufacturers will be used to design stronger tires. Two major players in the market will face the challenge: Michelin with NZG (Near Zero Growth) technology, which limits tire deflation (i.e., its ability to deform under pressure, which increases its resistance), with aramid reinforcements in the tire carcass, and Bridgestone with RRR (Revolutionary Reinforced Radial) that achieve It was NZG technology that allowed Concorde to return to the air before retirement.

Double cool kiss effect: the stiffer tire deforms less, thereby reducing the aircraft's fuel consumption during taxi phases.

Specific business model

In the business world, you no longer worry too much about buying tires. Because if you buy them, you have to store, collect, check, replace, recycle ... It's difficult. No, in the business world they are rented out. As a result, tire manufacturers have entered into a mutually beneficial relationship: take care of the management, supply and maintenance of aircraft tires and, in turn, charge the airlines a landing rate. Everyone is interested in this: companies don't worry about details and can anticipate costs, and on the other hand, manufacturers benefit from developing tires that last longer.

By the way, how long does a commercial aviation tire last? This is extremely volatile: it is highly dependent on the load of the aircraft, the length of the taxi phases, the ambient temperature, and the condition of the runway. Let's say, depending on these parameters, there is a range from 150/200 to 500/600 sites. This does little for an airplane that can make one or two flights a day. On the other hand, from the same carcass, these tires can be restore several times, maintaining the same performance each time as a new tire, because their carcass is designed for that.

A special case of fighters

Less weight, more speed, but also less volume (since space is even more limited on a fighter, aviation tires are 15 inches) and, above all, an extremely restrictive environment, since, for example, the flight deck of Charles de Gaulle is 260 meters, and the plane approaching at a speed of 270 km / h! So the power of the retarding force is downright brutal, and the plane manages to stop by hanging cables (called "threads" in the middle) held by a pump with pressures of up to 800 bar.

Takeoff speed is 390 km / h. Each tire still has to carry 10,5 tons and their pressure is 27 bar! And despite these limitations and extremely complex specifications, each tire weighs just 24 kilograms.

Thus, on these aircraft, the tire life is much shorter and may even be limited by the fit if the tire hits a strand during landing. In this case, it is replaced by a security measure.

Conclusion

Thus: an aircraft tire has the total volume of a truck tire. But a truck tire travels at a speed of 100 km / h, inflates to 8 bars, carries about 5 tons and weighs about 60 kilograms. Aircraft tires travel at 340 km / h, carry 20 to 30 tons and, as they are reinforced all over the place, weigh 120 kilograms and are inflated to 20 bars. All this takes technology, right?

We are betting that after reading this article, you will no longer board a plane without looking at its tires with another eye?