All About the Scissor Lift: The Complete Guide

Content

The scissor lift is part of a large family of lifting platforms, which includes cradles for spiders, toucans, articulated cradles, etc. Work that needs to be done at height requires suitable equipment, nessesary to use specialized equipment ... Therefore, you need a stable platform that allows you to work in complete safety. Explore in this article all the possibilities of using and how the scissor lift works.

Scissor lift for work at height

A special feature of this basket is the mechanism in the form scissors, which allows lift up wide platform up for work at height. It moves vertically and should be placed under the target area on level and stable ground to ensure the safety of everyone. There are different sizes, ranging from 10m scissor lift to 33m scissor lift, in diesel or electric version (depending on the model).

How to choose a scissor lift?

First, you must determine if the work will be done in premises (electric scissor lift) or outdoors (scissor lift). Then you must understand the working height and its nature, because installing rails on the ceiling or drilling a wall does not imply the same need. Finally, you must take into account possible restrictions, with which you may encounter and the flow of traffic to your site.

How does a scissor lift work?

Types of scissor lift

1. Diesel

Diesel powered scissor lifts are one of the most commonly used on construction sites ... Its design allows for a large lifting platform. Because they run on fuel, these gondolas are noisier and give off smoke. Therefore, they are usually designed to outdoor construction areas or areas where there is ventilation and noise may dissipate.

2. Electric

Electric scissors are also widely used and are often an alternative to diesel devices, as they are equipped with quiet and motorized mechanism ... It emits neither smoke nor noise: a good solution for indoor spaces with insufficient ventilation. These machines are also less cumbersome than their diesel counterparts, making them optimal for small spaces. Most often they are used for repairing ceilings, hanging panels or even trimming trees.

How to use a scissor lift safely?

Most of the work is making sure you are safe when the car turns around. Safety preparedness falls into four main categories:

1. Environment

It is important to ensure that the surrounding area is safe to help identify potential hazards such as power lines or uneven terrain.

2. Maintenance of equipment

If you have your own scissor lift be sure to follow the manufacturer's recommended maintenance schedule. Always check and inspect your machine before each use, paying particular attention to emergency stop. While the entire device should be checked regularly, it is especially important to check the fence to be sure it is safe.

3. Protective measures

Like all heavy equipment, scissor lift equipped with an emergency stop button that immediately turns off the device. Important check regularly this function as well as all other alarm systems.

4. Training

Although no official certification is required to operate the scissor lift, training and personal protective equipment are required before starting or working.

One of the biggest hazards and one of the most common causes of accidents with scissor platform Is bad stabilization. If it is not properly secured, the machine could tip over. Here are a few rules to be followed so as not to tip over the scissor lift:

- Always work for hard, even surfaces ;

- If your project takes place on rough terrain, be sure to use scissor lift, specially designed for this environment;

- Always completely lower working platform before moving equipment; work only when suitable weather conditions.

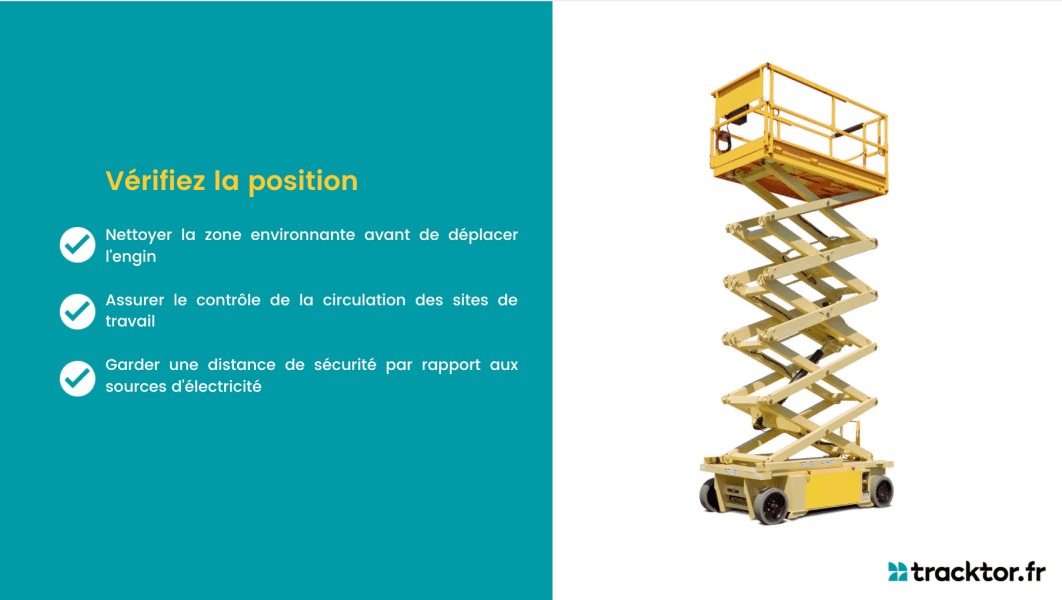

Location scissor lift can go a long way in preventing accidents. If installed incorrectly, crew members can be crushed or electrocuted. Therefore, it is very important that workers were trained using the machine. Also important watch the environment and carefully keep track of moving vehicles and stationary objects that may stand in the way of the gondola. For greater security, you need keep sufficient distance to energy sources.

Determine Which Scissor Lift You Need

When choosing a scissors lift, there are many criteria such as weight or size. If you do not take these criteria into account, you may receive equipment that does not meet your needs.

1. Determine the capacity

The first step is to determine the weight that needs to be lifted for your project, because every lifting device has its own limits. Therefore, you should be aware of this criterion depending on the work being performed.

2. Type of project

The type you need scissors lift depends on your project. Indeed, lifting heavy objects several meters high can be dangerous if the wrong machine is selected.

3. Platform size.

Most platforms rectangular although some are square. A larger platform will have a larger center of gravity. However, a great platform does not mean that it will be better, as it may not suit your needs.

4. Food

В diesel scissor lifts are the most common in Europe. In many cities, it is forbidden to use gas and diesel units indoors. The presence of a large amount of toxic fumes in a small space is dangerous to your health. So all that's left is these are power supplies for internal projects. You will need to make sure the battery is fully charged by plugging it into an electrical outlet.

Fall protection: do you need a harness?

When you are on the site, apply the rules of this site So on some sites wearing a seat belt can be compulsory ... All our scissor lifts are equipped with anchorage points for seat belts as well as guards to protect workers. Precautions to take to ensure the safety of your team are to become familiar with the make, model and type of equipment you are using.

Why rent a scissor lift?

Purchase scissor lift can be very expensive between buying, storing, maintaining ... If you need a car from time to time, renting is much more profitable.

By renting scissor lifts, you can avoid storage and transportation problems, for when you have your own gear it can be a real logistic headache, especially when you use a little.

Leases reduce maintenance and repair costs ... Once you have the pods, you need to keep them in good condition for safety and durability. Rent can reduce these costs or even eliminate it entirely.

Thus, you will be able to get modern equipment for your facilities thanks to rent ... Indeed, rental companies regularly purchase new equipment to maintain their competitive edge.

Renting helps you be more flexible when the business changes. If your business is going through a period of strong growth, you can rent more lifts ... During periods of recession, you can reduce your vehicle fleet or completely abandon rental ... You can also choose from different lift models or equipment types depending on the job and your budget.

What you must remember

There are many models of scissor lifts. Therefore, it is necessary to determine your needs in order to find a machine that suits your project. Renting is still the most economical solution if you need to use a scissor lift from time to time.