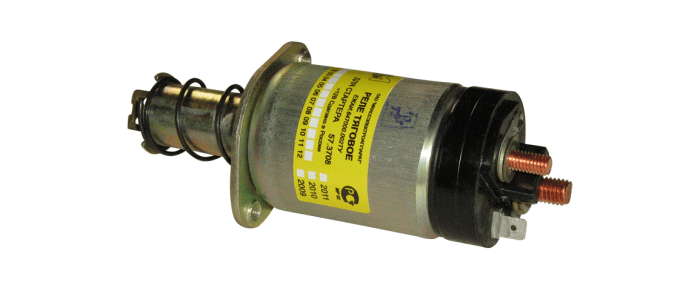

Starter Solenoid Relay

Content

Starter Solenoid Relay - This is an electromagnet that performs two functions in the ignition system. The first is bringing the starter bendix gear to the flywheel ring gear. The second is its return to its original position after starting the internal combustion engine. Breakage of the retractor relay threatens with the fact that The engine just won't start. There are not so many reasons for the failure of the relay. In this material, we will try to describe the signs and causes of breakdowns, as well as methods for diagnosing and repairing.

Solenoid relay with core

The principle of operation of the solenoid relay

Before moving on to malfunctions and methods for their elimination, it will be useful for car owners to find out the starter solenoid relay device and how it works. It should be noted right away that the mechanism is a classic electromagnet, consisting of two windings (holding and retracting), a circuit for connecting it to the starter, as well as a core with a return spring.

The scheme of the solenoid relay

At the moment of turning the ignition key, the voltage from the battery is supplied to the windings of the solenoid relay. This creates an electromagnetic field that moves the core located in its housing. That, in turn, compresses the return spring. As a result, the opposite end of the “fork” is pushed towards the flywheel.

In this case, the gear connected to the bendix is squeezed out until it engages with the flywheel crown. As a result of the engagement, the contacts of the built-in starter switching circuit are closed. further, the pull-in winding is turned off, and the core remains in a fixed position with the help of a working holding winding.

After the ignition key turns off the internal combustion engine, the voltage to the solenoid relay is no longer supplied. The anchor returns to its original position. The fork and bendix mechanically connected to it disengage from the flywheel. so, a breakdown of the starter retractor relay is a critical breakdown, due to which it is impossible to start the internal combustion engine.

Starter Solenoid Relay Diagram

Solenoid relay circuit

In addition to the previous point, we present to your attention starter solenoid circuit... With its help, it will be easier for you to understand the principle of operation of the device.

The retracting winding of the relay is always connected to the "minus" through the starter. And the holding winding is for the battery. When the relay core presses the work plate against the bolts, and a “plus” is supplied to the starter from the battery, then a similar “plus” is supplied to the “minus” output of the retracting winding. Because of this, it turns off, and the current continues to flow only through holding winding. It is weaker than the retractor, but it has enough strength to constantly keep the core inside the case, which ensures uninterrupted operation of the motor. The use of two windings allows you to significantly save battery energy during the start of the internal combustion engine.

Signs and causes of relay failure

The external signs of a breakdown of the starter solenoid relay include the following aspects:

- When turning the key in the ignition no action occurs to start the internal combustion engine, or starting is possible only after several attempts are made.

- After starting the internal combustion engine, the starter continues to rotate at high speed. By ear, this can be determined by the strong buzz of the mechanism.

a breakdown in the operation of the relay is one of the reasons that the car does not start, and there can be several reasons for its breakdown:

- failure (burnout) inside the relay of the contact plates (popularly referred to as “dimes”), a decrease in the area of their contact, “sticking”;

- breakage (burning) of the retraction and / or holding winding;

- deformation or weakening of the return spring;

- short circuit in the pick-up or holding winding.

How to check the starter solenoid relay with a multimeter

If you find at least one of the listed signs, then the next step to eliminate the breakdown will be a detailed diagnosis.

How to check a solenoid relay

There are several methods for checking the solenoid relay. Let's break them down in order:

- Relay triggering can be determined quite simply - at the moment of starting there is a clickproduced by a moving core. This fact speaks about the serviceability of the device. If there is no click, then the starter retractor relay does not work. If the retractor clicks, but does not turn the starter, then the likely reason for this is the burning of the relay contacts.

- If the retractor relay is triggered, but at the same time a kind of rattling is heard, then this indicates faults in one or both relay coils. In this case, the starter solenoid relay can be checked using an ohmmeter by measuring the resistance of its windings. you need to pull the core and the return spring out of the housing, and then check the resistance between the windings and the “ground” in pairs. This value must be within 1 ... 3 ohms. After that, insert the core without a spring, close the power contacts and measure the resistance between them. This value should be 3…5 ohms (the value depends on the specific relay). If the measured value is lower than the indicated numbers, then we can talk about a short circuit in the circuit and the failure of the windings.

Starter solenoid relay repair

Worn relay contact plates

On many modern machines, the retractor relay is made in a non-separable form. This is done for two reasons. First, this increases the reliability of the mechanism and its durability due to mechanical protection from external factors. The second is because automakers want to get more profit from the sale of their components. If your car has just such a relay, then the best way out in this case is to replace it. Write down the brand of the relay, its technical parameters, or rather, take it with you, and go to the nearest store or car market for a similar new one.

However, some car owners carry out their own repairs. But at the same time you need to know how to disassemble starter retractor relay. If the relay is collapsible, then it can be repaired. In the case of non-separable repair is also possible, but in a small amount. namely, when burning “pyataks”, improving and cleaning the contact. If one of the windings burned out or “short-circuited”, then such relays are usually not repaired.

For further work, you will need a flat-blade screwdriver, as well as a soldering iron, tin and rosin. The disassembly of the relay begins with the fact that you need to pull the core out of it. After that, two are unscrewed, which hold the top cover, where the coil contacts are located. However, before removing it, you need to unsolder the mentioned contacts. Wherein it is not necessary to unsolder both contacts. Usually, in order to get to the “pyatak”, it is enough to unsolder only one contact and lift the cover on one side.

Disassembly and repair of the solenoid relay

Repair of the retractor relay VAZ 2104

then you need to unscrew the bolts holding the “pyataks” from the upper side and get them. If necessary, they should be reviewed. That is, clean them with sandpaper in order to get rid of soot. A similar procedure must be performed with their seats. Using a plumbing tool (preferably with a flat-blade screwdriver), clean the seat, removing dirt and soot from there. The relay housing is assembled in the reverse order.

Disassembly and assembly of a collapsible relay is similar. To do this, you need to unscrew the stud bolts and disassemble its body. This will take you to the inside of the device. Revision work is carried out in a similar way to the above algorithm.

Types of solenoid relays and their manufacturers

Let us briefly touch on the retractor relays used on VAZ cars. They are divided into four types:

- for non-gear starters of the VAZ 2101-2107 models ("Classic");

- for non-gear starters of the VAZ 2108-21099 models;

- for VAZ gear starters of all models;

- for AZD starter gearboxes (used in models VAZ 2108-21099, 2113-2115).

In addition, as mentioned above, they are divided into collapsible and non-collapsible. Older models are collapsible. New and old are interchangeable.

For VAZ cars, retractor relays are produced by the following enterprises:

- Plant named after A.O. Tarasov (ZiT), Samara, RF. Relays and starters are produced under the KATEK and KZATE trademarks.

- BATE. Borisov plant of automotive and tractor electrical equipment (Borisov, Belarus).

- Kedr company (Chelyabinsk, RF);

- Dynamo AD, Bulgaria;

- Iskra. Belarusian-Slovenian enterprise, whose production facilities are located in the city of Grodno (Belarus).

When choosing one or another manufacturer, it should be taken into account that the highest quality and most common brands are KATEK and KZATE. also remember that if an AZD starter is installed on your car, then “native” relays manufactured by the same company are suitable for them. That is, with the products of other factories they are not compatible.

Results

The starter retractor relay is a simple device. but its breakage is critical, as it will not allow the engine to start. Even an inexperienced car enthusiast with basic locksmith skills can check and repair the relay. The main thing is to have the appropriate tools at hand. If the relay is non-separable, we still advise you to replace it, since, according to statistics, after the repair is completed, its service life will be short. Therefore, if the solenoid relay does not work in your car, buy a similar device and replace it.