Clutch release bearing: principle of operation, symptoms of failure

Content

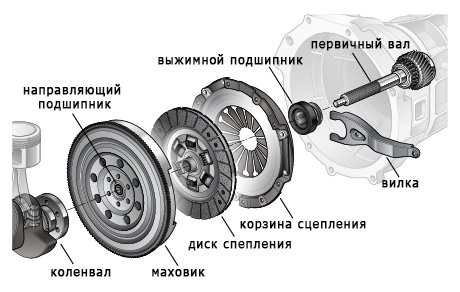

Today, the most common clutch systems are with two discs - the master, rigidly coupled to the crankshaft and the slave, which transmits torque to the gearbox. To change gears or to idle the car, the clutch discs must be disconnected, which is carried out using a release bearing that pulls the driven disc away from the drive.

Release bearing location

It is an important element of the clutch system, and at the same time one of the most vulnerable parts. Clutch release bearing in the process of movement of the car is at rest, engaging in work only when changing gears. The breakdown of such a small part guarantees the impossibility of further operation of the car, so you need to change the bearing immediately when it appears clear signs its breakdown.

The part costs from 300 to 1500 or more rubles, depending on the manufacturer and model of the car. Replacing a bearing at a service station will cost 3000-7000 rubles, so if you have the desire, opportunity and a normal set of auto tools, it makes sense to do it yourself and save a lot.

Release bearing types

Two types of release bearings are now common:

- roller or ball - mechanical assemblies transmitting force to the bearing through a rigid bundle of rods;

- hydraulic - here the force is created by hydraulics, making the clutch pedal much easier to depress.

Hydraulic release bearing

Roller release bearing

The mechanical clutch release bearing can be called a detail from the past, because Moskvich, VAZ and other old cars were equipped with it. On new machines, even budget ones, mainly hydraulic systems are used. Although a number of domestically produced cars are now also equipped with mechanics, in order to reduce the cost and simplify.

Operating principle

The purpose of the release bearing is to ensure that the clutch is connected and disengaged when the pedal is depressed in the passenger compartment. The principle of the part is quite simple:

- the driven disc is pressed against the flywheel by the pressure disc, due to which the clutch is provided;

- pressure on the pressure plate is provided by a diaphragm spring, on the inner petals of which the clutch release bearing acts;

- the movement of the bearing, initiating the separation of the discs, is provided by the clutch fork.

Release bearing in the vehicle clutch system

Causes and signs of release bearing breakage

The reason for the breakdown of this part is uneven loads on it at the moment when the clutch is depressed, and it goes back together with the driven disc. For this reason, it is strongly discouraged to hold the clutch pedal in gear for a long time. In principle, this is a reliable and durable part, and it breaks down most often in novice motorists.

The most important symptom of bearing wear is the appearance of a light knock when depressing the clutch pedal. If the sound appeared in the summer, this is almost a guarantee of future problems, but if it came along with frost, there may be an elementary change in the linear dimensions of the bearing cup due to a drop in temperature outside. The release bearing in most cars has an undeniable advantage - high strength, so even if noise appears, you can afford to do nothing for a while, but to see if it gets worse.

How to check the release bearing

Checking the clutch release bearing is carried out by ear when depressing the pedal, when it is in operation (rotates). Depending on the stage and nature of the wear (a small amount of lubricant or the development has gone), the sound will be different, it can just hum or make noise or make other unpleasant sounds in the area of the box. But do not confuse these sounds with those that can occur when the clutch pedal is not even depressed, since such a sign will indicate the bearing of the input shaft.

Replacing the clutch release bearing

If the bearing still needs to be changed, you will have to perform the following sequence of actions:

- dismantling of the checkpoint;

- disconnecting the ends of the spring clip from the clutch;

- removal from the bearing guide sleeve;

- detaching the spring holder;

- removing the bearing from the coupling and installing a new part.

Before installing the part on the guide bush, their surfaces must be generously lubricated with grease.

In Conclusion, it should be noted that release bearings can serve up to 150 kilometers, however, they often have to be changed every 50 km due to driver errors and bad roads that destroy the entire car, including the clutch.