Replacing the clutch kit Matiz

Vehicle operation requires regular care and maintenance. So even with very careful and careful operation of the car, parts fail. A rare, but very regular breakdown of Matiz is considered to be clutch failure. Consider the process of replacing this structural element, and also discuss which kit can be installed on Matiz.

Replacement process

The process of replacing a clutch on a Matiz is almost identical to that on all other cars of Korean origin, since they all have similar design features. How to replace a structural element, you will need a pit or lift, as well as a set of certain tools.

So, let's consider what is the sequence of actions for replacing the clutch on the Matiz:

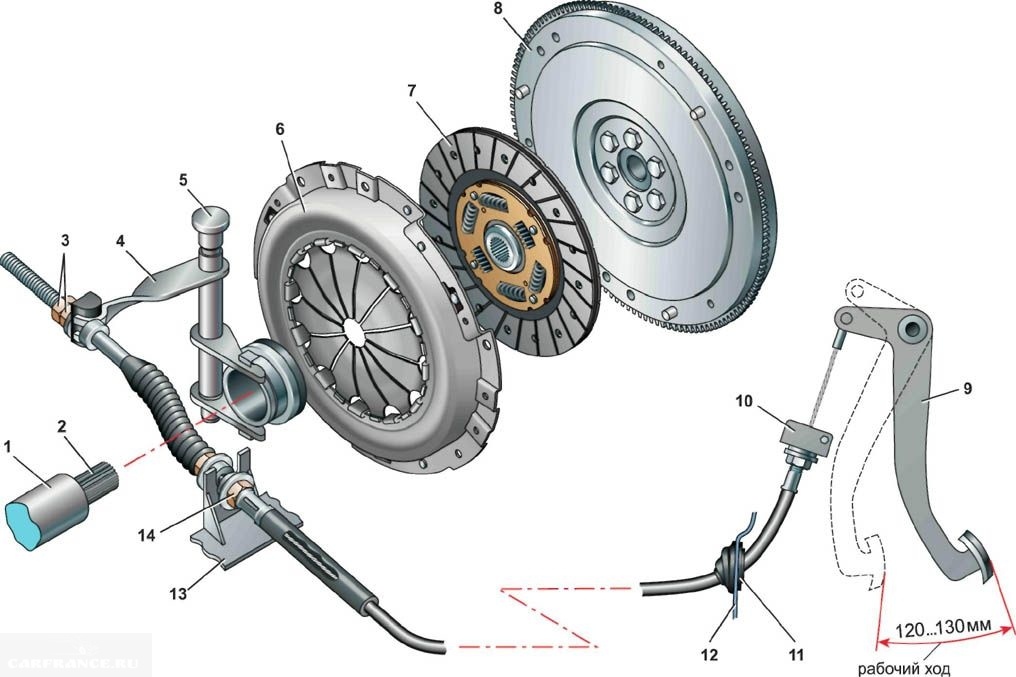

- Disconnect the negative battery terminal. It should be noted that there are some differences in the design and installation of the clutch mechanism of this car, produced before 2008 and after. But they are mainly related to the size of the puck and basket, but otherwise they are completely insignificant and the procedure is the same everywhere. So, today we will install the Trial brand clutch, which includes the release bearing, pin supports, basket, clutch disc and centralizer. It should be noted that replacing the clutch in a Daewoo Matiz car is the second most difficult procedure, second only to engine repair. That is why it is necessary to prepare yourself and take on it only if you have the right tool, all the necessary details, and most importantly, your own experience in carrying out such repair work. There are several different ways to replace a Daewoo Matiz clutch. This is written in many educational and reference books. In this article we will talk about one of them, which we consider the most optimal and least time-consuming. Also, together with the replacement of the clutch, we recommend replacing the crankshaft rear oil seal, the shift fork, and also installing a new left and right CV joint. So, first we remove the air filter housing by loosening the clamp on the corrugated hose going to the throttle valve, and unscrewing the three bolts securing the air intake and filter housing, disconnecting the gas recirculation hose.

We also disconnect the gas recirculation hose from the crankcase. Now, to make it more convenient to work, disconnect and remove the battery. After that, we also remove the battery pad, although this is not entirely necessary, and also turn off all the sensors located on the gearbox support. Now we bring the head to 12 and unscrew this support. At the same time, we recommend that all bolts, nuts and washers, if possible, be inserted back to the places where they were removed from, so that they are not lost, and then during assembly it would be possible to quickly find them and do not confuse them. It is better to lift the unscrewed bracket and fix it together with the previously disconnected sensors so that they do not interfere with the subsequent removal of the gearbox. With the same 12 head, we unscrew the bracket for the Daewoo Matiz cooling system pipe in the place where it is attached to the gearbox bell.

Next, disconnect the gear selection cable, for which we remove its clamps with which they are attached to the support. We unhook and remove the supports from the shafts of the gear levers. Then remove the shift cable from the brackets. Disconnect the clip holding the cable sheath under the shift levers. Also, with a 12 head, we unscrewed the bolt and disconnected the negative gear shift terminal on the Daewoo Matiz gearbox.

- Using the prepared set of tools, we disassemble the bolts securing the gearbox to the power unit and disconnect the elements. You should be very careful not to damage other structural elements. Under the gearbox shift bracket there are two bolts and a nut that need to be unscrewed with the same 12 head. Now we finally have direct access to the gearbox. To start disassembling the gearbox, you need to start the upper front screw by 14 from its attachment to the engine. Additionally, it is also necessary to pull out the lower front bolt located behind the camshaft position sensor. Now, using a 14-inch head and a long handle, unscrew the rear upper bolt from the Daewoo Matiz gearbox. The next step is to work under the car. To do this, lift it on a lift or jack. After that, remove the left front wheel. We expand and turn off the hub nut. Now with a 17 key we fasten the steering knuckle bolt to the suspension strut, and with the other key we unscrew the nut.

- Do the same for the second screw. We take out the bolts and then remove the fist from the bracket, which is on the suspension strut. Now we take the fist a little to the side and remove the CV joint from the steering knuckle. After that, we return the cuff to its place in the bracket to avoid stress on your hose. In this case, everything works near the ends of the wheels and you need to move on to operations under the car. Here you need to remove the gearbox protection and drain the oil from the Daewoo Matiz gearbox. If it is clean, it is worth draining it into a clean container, so that you can pour it back later. If not, pour into any container. By the way, this is a good procedure for replacing the clutch, which can be changed at the same time, and the oil in the gearbox of a Daewoo Matiz car. You also need to remove the left drive from the gearbox and remove it. In our case, it turned out that the clutch cable bushing was torn, and the cable itself was completely dry.

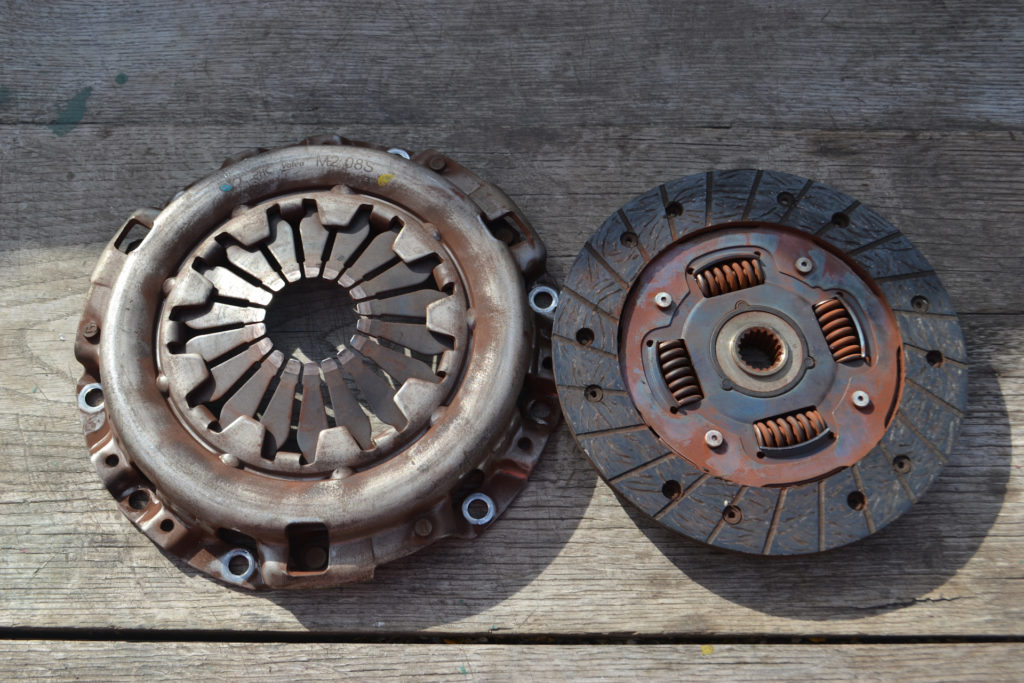

- With the two most important parts removed, the clutch kit can be seen. First of all, it is necessary to conduct an external inspection of the basket, or rather its petals for wear. But, as practice shows, the clutch kit on the Matiz must be completely changed. It is cost effective and also much more convenient. This, of course, is a reason to replace it. In the meantime, we release the cable, unscrew the fixing nut by 10 and remove it from the latch and bracket. Now we take the head at 24 and unscrew the filler plug of the gearbox of the Daewoo Matiz car by four threads. This is done so that air enters the box through it. After that, we take the tetrahedron and unscrew the drain plug on the box. Now we drain the oil, and during this time we clean the drain plug. After completing this work, carefully insert the bracket between the drive and gearbox.

After that, clicking on it removes the left disk. We carry out a thorough inspection to identify damage and burst anthers. After that, replace the drain plug and tighten it well. After that, as before, we also show the right inner CV joint. But because it walks freely, it can be left in a semi-stretched position. Next to the gearbox drain plug is another 12mm screw that secures the wire braid. Open it too. We simply remove the bolt, set the brace aside, and screw the bolt back into place. Disconnect and remove the speed sensor, which is also attached to the gearbox. We unscrew and remove the support for the gear selection cables from the gearbox. Now we remove the longitudinal rod by unscrewing the nut by 10 and two bolts by 12. - Loosen the clutch cover. We remove the casing that prevents dirt from entering and wash it in the crankcase (“half-moon”) by unscrewing two small 10 screws for this. Now there is another 14 nut under the starter that holds the gearbox in connection with the engine. Open it too. Now there is practically nothing to support the box, so it has to be supported with a brace or something else. Next, we unscrew the mount of the gearbox cushion, since now it rests exclusively on this cushion and is directed. These are two 14 bolts. Now the box is completely released, so you need to gradually loosen the rack and move it a little to the left in the direction of the car. Thus, it will detach from the guides and can be lowered. In this case, the stabilizer will interfere with this a little. But you need to carefully show the checkpoint first to the left, then down and everything will work.

When performing this operation, it is desirable to have an assistant nearby, since the gearbox itself is quite heavy. We now have full access to the Daewoo Matiz clutch mechanism. In addition, it is possible to fully inspect the gearbox, replace the clutch release and clutch fork. When inspecting the gearbox, you need to pay attention to the guides. Everyone should be in their place. If something is left in the engine housing or starter, as we have, then it needs to be removed from there, flattened a little and hammered into place in the Daewoo Matiz housing. In this case, the main thing is that all guides are tightly tightened, otherwise they can get into the "bell" or gearbox when the engine is running and cause a lot of trouble. After that, take a pry bar with a flat end or a wide flat screwdriver and wedge the handlebar so that it cannot turn and is fixed in one position. - We fix the crankshaft by fixing the flywheel. Now we tear out six screws that hold the flywheel. Unscrew and then remove the clutch basket and disc. Following this, we unscrew the six screws, having previously fixed the steering wheel, and then remove it. In this case, you need to pay attention that there is a special pin inside the flywheel, which, when installing the flywheel, must fall into the appropriate place on the crankshaft rod. If this does not happen, then the crankshaft sensor will give you incorrect information, since the flywheel will be installed with a certain offset. Now inspect the crankshaft oil seal for oil leaks.

If everything is fine, then there is no point in changing. If there is an oil leak, it is better to replace the specified oil seal. Although in any case it is better to replace it, and at the same time the input shaft bearing in the flywheel of a Daewoo Matiz car. So, we take out the cable gland from the socket using a hook made from an old screwdriver. When doing this, care must be taken not to damage the surface of the crankshaft and the aluminum O-ring. You can also do this in another way: carefully wrap two self-tapping screws into the cable gland, and then use them to pull it out of the socket. Then carefully and carefully clean the entire seat. Now we take a new oil seal and apply a modern and expensive high-temperature sealant to it in order to eliminate costly and unforeseen repairs in the future. After that, the sealant was leveled with a finger to get a thin layer on the stuffing box, and installed it flush with the engine housing. - We take out the basket and disk. Now press out the input shaft bearing on the flywheel. For this we have a special press. With it, we install a new bearing in its place. It does not require any lubrication. Now let's move on to the checkpoint of the Daewoo Matiz car itself. Loosen and remove the shift lever. Then we carefully inspect it and if cracks or other damage appear, it is better to replace it with a new one. Now we feed a little and drive the release bearing into the gearbox.

Before installing the new version, we strongly recommend changing the fork. The fact is that in any case, it enters the bearing, as a result of which characteristic mechanisms are formed in it. When working with a new smooth bearing, it will again try to cut into it, causing vibration and subsequently misalignment of the bearing itself. And through the clutch cable, the clutch pedal in the passenger compartment will vibrate accordingly. To remove the plug, you need to take a simple device, like ours. So, we take this device, install it on the fork body from the inside, and use a hammer to remove the oil seal and bronze bushing that fix the plug in the “bell” of the gearbox. After that, it is easily removed. Now another important point: you need to remove the guide pin from the old fork and press it into the new one. - After installation, you need to check the performance of the node. The next point is to thoroughly clean the shaft on which we will put the release bearing. But first we lubricate its inner surface with synthetic grease. In this case, it will be better to rotate around its axis. After that, we install the fork and release bearing in place, placing them on the appropriate hitch. Now, in reverse order, using the already known devices, we knock out the bushing and oil seal of the Daewoo Matiz clutch fork. Here we must also remember that if the oil seal is leaking on the gearbox axle shafts, then now is the time to replace them too. If everything is fine with you, then the repair work at the checkpoint can be considered completed. Now let's start assembling the clutch mechanism. To do this, install the flywheel in its place, while aligning its pin with the corresponding place on the engine. It is best to use a torque wrench to properly tighten the flywheel mounting bolts. Having adjusted the head to 14, with the help of this wrench we will make sure that all the bolts are correctly tightened with the required force of 45 N / m. You also need to remember that the fastening of all large parts of the car, including the Daewoo Matiz, is tightened in several steps and always diagonally. Next, install the clutch basket.

In this case, the disc with the thick side is placed inside the basket. We fix the entire basket assembly with the same centralizer and then correct the disk relative to the basket along its edges, making sure that there is no play. Now we install the basket on the flywheel and the bait with three bots, and then squeeze them in dynamics. After that, you can loosen the centralizer and safely remove it. Disc tray in place. Following this, a Daewoo Matiz car is installed instead of a checkpoint.

Product selection

As practice shows, most motorists are careless about choosing a transmission kit. Typically, they rely on cost and try to save money. That is why this node often fails quite quickly. Therefore, the choice of clutch on the Matiz must be taken seriously.

In this case, you need to carefully monitor that nothing interferes with the installation of the box in its place. Also check again that all the guides are in place. We install in the reverse order: first we feed the gearbox on the left along the direction of the car, and then align it with the guides. You also need to get the right drive from the inner CV joint to get into the crankcase seal. Therefore, we slowly move the box forward and up so that the input shaft coincides with the hole in the basket and enters the bearing. Check again if something is preventing you from installing the gearbox in its place, if there are other units between it and the engine. And as soon as the box is in place, fix it with a nut, which is located between the CV joint of the Daewoo Matiz car and its starter. This is done so that the gearbox does not reverse and now you can safely insert all the bolts into place. Prior to this, we recommend lubricating all threaded connections with grease during assembly. In addition, before starting the operation, we recommend that you immediately adjust the clutch, since the cable has been removed.

And then initially we advise you to drive carefully, without excessive aggressiveness, so that the clutch works. You should also keep in mind that after a few days, after the clutch wears out, your pedal may drop a little lower or, conversely, rise a little higher. There is nothing wrong with this, it just requires additional adjustment of the clutch. Another very important tip. If you do change the clutch in a car service, then when you drive the car after repair, make sure that the clutch pedal does not vibrate, there is no knocking or extraneous noise during engine operation. The car itself moves smoothly and easily without jerking. This will indicate that the clutch is installed correctly. So our Daewoo Matiz clutch replacement repair is over, your pedal can go down a little or vice versa, get a little higher. There is nothing wrong with this, it just requires additional adjustment of the clutch.

Another very important tip. If you do change the clutch in a car service, then when you drive the car after repair, make sure that the clutch pedal does not vibrate, there is no knocking or extraneous noise during engine operation. The car itself moves smoothly and easily without jerking. This will indicate that the clutch is installed correctly. So our Daewoo Matiz clutch replacement repair is over, your pedal can go down a little or vice versa, get a little higher. There is nothing wrong with this, it just requires additional adjustment of the clutch. Another very important tip. If you do change the clutch in a car service, then when you drive the car after repair, make sure that the clutch pedal does not vibrate, there is no knocking or extraneous noise during engine operation. The car itself moves smoothly and easily without jerking. This will indicate that the clutch is installed correctly.

And now our Daewoo Matiz clutch replacement repair is completed, there are no knocks and extraneous noises during engine operation. The car itself moves smoothly and easily without jerking. This will indicate that the clutch is installed correctly. And now our Daewoo Matiz clutch replacement repair is completed, there are no knocks and extraneous noises during engine operation. The car itself moves smoothly and easily without jerking. This will indicate that the clutch is installed correctly. So our Daewoo Matiz clutch repair has ended.

Most motorists turn to a car service for a replacement block, where they select kits according to the article. I repeatedly offer motorists analogues that are not inferior in quality to the original, and in some positions surpass it.

Original

96249465 (manufactured by General Motors) — the original clutch disc for Matiz. The average cost is 10 rubles.

96563582 (General Motors) — original clutch pressure plate (basket) for Matiz. The cost is 2500 rubles.

96564141 (General Motors) - catalog number of the release bearing. The average cost is 1500 rubles.

Hack and predictor Aviator

Replacing the clutch kit on Matiz is quite simple, even with bare hands. This requires a well, a set of tools, hands that grow from the right place, and knowledge of the design features of the vehicle.