Changing the oil in the gearbox

There are parts and components in the car that many drivers have not even heard of or have a very vague idea about. The gearbox is one such node.

The word reduce means to lower, reduce. A gearbox in a vehicle is a mechanical device designed to increase the torque that is transmitted from the internal combustion engine to the wheels by reducing the speed of rotation. The reduction in rotational speed is achieved through the use of a pair of gears, of which the leading one has a smaller size and fewer teeth than the driven one. The use of a gearbox reduces the load on the internal combustion engine and gearbox.

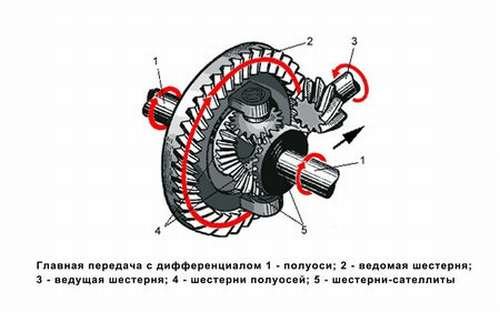

In front-wheel drive cars, the gearbox is usually located in the same housing with the gearbox. The drive gear (3) receives torque from the secondary shaft of the gearbox, and the driven gear (2) transmits increased torque to (4; 5).

the purpose of the differential is to distribute rotation to both axle shafts (1) of the driving wheels with an arbitrary ratio of angular velocities. This allows the wheels of the same axle to rotate at different speeds, for example during cornering. Read more about the device and types of differentials in a separate one.

In rear-wheel drive vehicles, the gearbox is mounted on the rear axle and works in a similar way.

In the presence of all-wheel drive, the gearboxes are installed both in the gearbox and on the rear axle, and they are interconnected by means of a cardan shaft.

The main parameter of the gearbox is the gear ratio, that is, the ratio of the number of teeth of the larger (driven) and smaller (driving) gears. The larger the gear ratio, the more torque the wheels receive. Devices with a large gear ratio are used, for example, in freight transport, where power is much more important than speed.

This unit works in a rather intense mode, and therefore its parts gradually wear out. If the machine is operated under severe conditions, the wear process is accelerated.

The hum is characteristic of broken bearings. It gets stronger as the speed increases.

Crackling or grinding in the gearbox is a symptom of worn gears.

It is also possible that the seals are defective, which can be detected by traces of gear lubricant on the housing.

Any mechanic requires lubrication. It reduces the friction of the interacting parts, protects them from corrosion, promotes the removal of heat and wear products. The gearbox is no exception in this sense. Lack of oil or its poor quality will inevitably affect the condition of the assembly parts.

High temperatures degrade the performance of the lubricant over time, wear products gradually accumulate in it, and due to worn seals, oil can leak through the seals. Therefore, it is necessary from time to time to diagnose the level and quality of the oil in the gearbox and replace it.

The typical shift interval recommended by automakers is 100 kilometers. In Ukrainian conditions, the lubricant should be changed one and a half to two times more often. And if the car is operated in heavy mode, then it is better to reduce the shift interval to 30 ... 40 thousand kilometers. It is logical to combine checking and changing the oil in the gearbox with the next maintenance.

As a rule, the same is poured into the gearbox as into the gearbox. But there are exceptions. Therefore, it is better to specify the type of lubricant and its volume in the operational documentation of a particular vehicle.

When purchasing lubricant for the gearbox, do not forget about flushing oil. It will be needed if the drained oil is heavily contaminated.

To check the oil level, unscrew the filler plug. The oil should be flush with the hole or a set of millimeters lower. There is no special probe here, so use an impromptu one. In extreme cases, you can just feel it with your finger, but be careful: if the transmission has recently been in operation, the oil may be hot.

The quality of the oil can be diagnosed by pumping out a little with a syringe. Normally, it should be transparent and not very darkened. Dark, turbid liquid with traces of foreign matter should be replaced, even if the change date has not yet come.

Warm oil will drain faster, so you must first drive 5 ... 10 kilometers.

1. Put the car on a viewing hole or lift it on a lift.

2. In order not to get burned, take care to protect your hands.

Substitute a container of a suitable volume and unscrew the drain plug. When the oil starts to flow out, also unscrew the filler plug.

When the oil barely drips, tighten the drain plug.

3. If the drained grease is dirty, flush the gearbox. In the absence of flushing oil, you can use the oil that will be filled in instead of the used one. Pour the flushing fluid into the filling hole using a large syringe or funnel with a hose. The volume should be approximately 80% of the norm.

Tighten the plug and drive the car for 15 kilometers. Next, drain the flushing fluid. Repeat the flushing process if necessary.

4. Fill in new grease so that its level reaches the lower edge of the filler hole. Screw on the plug. Everything, the process is completed.

As you can see, the procedure for changing the lubricant in the gearbox is quite simple and does not require special skills. The cost of the oil itself will not ruin you, but it will save a very expensive unit from premature failure.