Replacing the valve stem seals of a car engine - signs of wear and tips

Content

If the valve stem seals fail, the engine starts to consume more oil. During operation of the power unit, there is an abundant formation of thick smoke. Consider why a problem with these small items can have serious consequences for a car.

Why do you need valve stem seals

The valve stem oil seal is the name of this part. From its name it follows that it is installed on the valve in the gas distribution mechanism. The job of the caps is to prevent the engine grease from entering the cylinder through the open valve. They look like rubber glands with compression springs.

The number of these parts is identical to the number of valves. When the valve opens the corresponding hole, it must be dry. But at the same time, due to constant friction, the rod must receive the necessary lubrication. Both effects can be achieved with rubber bushings. Since they are made of elastic material, they wear out as a result of constant mechanical and thermal stress, as well as exposure to engine oil.

How valve stem seals work

The valve stem can be made in two different designs:

- Cuff. It is pushed onto the valve stem and inserted into its guide. It protrudes from the cylinder head. They cost less (compared to the next modification) and can be quickly replaced. The only problem is that dismantling requires a special device.

- Valve oil seal. It fits under the valve spring. This element fixes the cap and also presses its edges, ensuring a stable sealing of the head in this part. These parts are more reliable, since they do not experience such temperature stresses as previous analogues. Also, they are not in direct contact with the guide sleeve, therefore, the mechanical load on the cap is less. No special tool is required to replace such modifications. The disadvantage is the high price. If you buy a budget set of caps, you can end up on low-quality items made from a less stable material. Preference should be given to options from acrylate or fluoroelastomer.

In order for the gas distribution mechanism to work without premature wear of the rubbing parts, it must constantly contain motor lubricant (how the timing mechanism works and how it works is described in a separate article). However, oil must not enter the cylinder cavity.

If valve stem seals were not used in the timing, the lubricant would be mixed with fuel and air. In its pure form, BTC is removed from the cylinder without residues after combustion. If oil gets into its composition, then this product forms a large amount of soot after combustion. It accumulates on the valve seat. This leads to the fact that the valve ceases to press tightly against the head body, and, as a result, the tightness of the cylinder is lost.

In addition to the valve, carbon deposits form on the walls of the fuel chamber (a cavity that is not in contact with the oil scraper rings), and on the pistons, and on the compression rings. Such "smokiness" of the motor leads to a decrease in its efficiency and reduces its working life.

The main signs of wear on the valve stem seals

How to determine that the valve stem seals have become unusable and need to be replaced? Here are some of the main "symptoms":

- The engine began to take oil. This is due to the fact that the cap does not collect the lubricant, but it enters the cylinder chamber.

- When the driver presses the accelerator, thick gray or black smoke escapes from the exhaust pipe, which is not caused by a cold engine start in winter (this factor is explained in detail here).

- Due to heavy carbon build-up, the valves do not close tightly. This affects the compression, which leads to a decrease in the performance of the internal combustion engine.

- Carbon deposits appeared on the electrodes during periodic replacement of the spark plugs. Read more about the types of carbon deposits in separate review.

- In a more neglected state, the smooth operation of the engine at idle is lost.

- With good ignition and fuel supply systems, fuel consumption has increased significantly. It is important to make sure that the driving behavior of the driver does not change towards an aggressive style.

None of the signs on this list are 100 percent evidence of worn caps. But in the aggregate, they make it possible to determine that the problems are with the valve seals.

In old cars of the domestic auto industry, wear will begin to manifest itself after the car has covered about 80 thousand kilometers. In modern models, a more reliable material is used, due to which the parts have an increased resource (about 160 thousand kilometers).

When the valve stem seals have lost their elasticity and oil begins to pass through, the engine will imperceptibly begin to decrease in power after each kilometer traveled.

Consequences of driving with worn valve stem seals

Of course, you can ride with worn valve stem seals for a while. But if the driver ignores the signs listed above, he will start the state of the unit to such an extent that, in the end, it will use up its resource, even without having passed the prescribed mileage.

When the compression in the cylinders drops, the driver will have to crank the engine more to maintain the usual driving regime. To do this, he will need to use more fuel. In addition to economic considerations, driving with worn-out caps will lead to unstable motor operation.

The power unit will gradually lose idle speed. There will be problems with starting the engine, and at traffic lights and railway crossings, the driver will need to constantly pump the gas. This is distracting, which reduces his reaction in emergency situations.

When the engine starts to consume a large amount of oil, the motorist has to add lubricant. If its volume falls below the minimum, the engine may experience oil starvation. Because of this, repairing an internal combustion engine will definitely be expensive.

If a car has a catalyst in the exhaust system, this part will quickly fail, since its main task is to clean the exhaust from harmful impurities contained in the smoke. Replacing the catalytic converter in some vehicles is much more expensive than installing new valve stem seals.

In addition to safety (even if the driver is so proficient in driving that he can perform several actions while driving at the same time) the motor will experience additional stress. And due to the increase in carbon deposits inside the unit, its parts will heat up more (due to the additional layer, the thermal conductivity of the metal elements is lost).

These factors bring the internal combustion engine closer to overhaul. In the case of some budget cars, this procedure is so expensive that it is cheaper to buy another car.

Replacing valve stem seals

In order for the repair to be of high quality, the master must adhere to the following recommendations:

- You will need a special tool to remove worn-out caps. Thanks to this, the chance of breaking nearby parts is reduced;

- When the oil seals are replaced, the intake and exhaust ports of the engine are exposed. To prevent debris from getting there, they must be carefully covered with a clean rag;

- To prevent damage to the new valve stem seal during installation, it should be lubricated with engine oil;

- You should not purchase cheap elements, since less reliable material can be used for their manufacture;

- Older motors can be fitted with newer oil seals. However, in the case of modern motors, only new caps must be used. Old-style counterparts should not be installed.

If the work is done for the first time, then it is better to carry it out in the presence of a master who understands all the subtleties of the procedure. This minimizes the chance of doing something wrong.

Replacing valve stem seals with your own hands

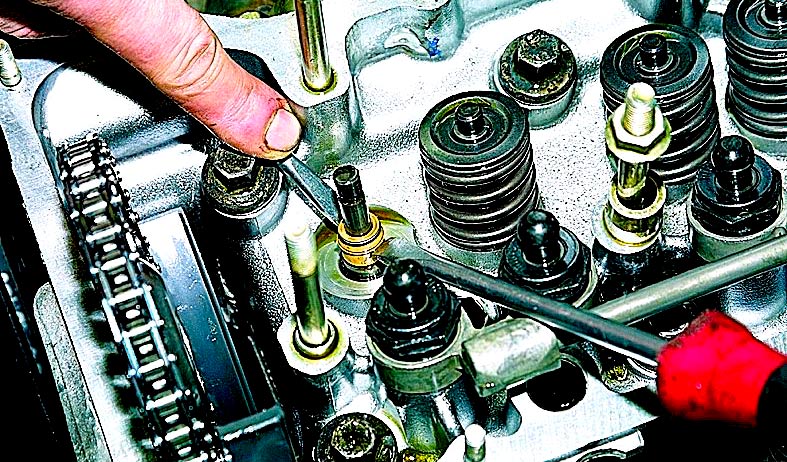

To carry out the work on self-replacement of the valve stem seals, you will need the necessary tools - a desiccant for valves, wrenches of the appropriate size, a mandrel for installing the seals, as well as special pliers for dismantling the oil seals.

There are two options for performing work:

- Without removing the cylinder head. When performing this procedure, it is worth considering that when replacing the oil seal, the valve may fall into the cylinder. For this reason, top dead center must be set on each valve set. This will hold the piston in place. In this case, the work will be cheaper, since after replacing the oil seals, you will not need to grind the head to replace the gasket.

- With head removal. The procedure is almost identical to the previous one, but it is better to follow it if you need to replace the cylinder head gasket along the way. It will also come in handy when in doubt about the good condition of the compression rings and pistons.

Replacement of oil seals takes place according to the following scheme:

- Remove the valve cover;

- We set the TDC or dismantle the head;

- The desiccant is used to compress the spring and release the crackers;

- Next, dismantle the oil seal with pliers. Do not use pliers, as they can scuff the mirror of the valve stem;

- We install the oiled cap and press it through the mandrel with light hammer blows (at this stage, you need to be extremely careful, since the part is easily deformed);

- You can determine the correct installation in the seat of the cap by the characteristic dull sound during a light tap with a hammer;

- All oil seals are changed in the same way;

- Dry the valve (install the springs in their place);

- We assemble the gas distribution mechanism.

Some motorists use special auto chemicals that make old rubber elements more elastic, thereby prolonging their working life. It is possible to restore worn-out caps (if the material is simply hardened), but this is not economically justified, because very soon the procedure will need to be repeated.

Since during dismantling and subsequent assembly of the timing it is required to correctly set the necessary marks, it will be much cheaper to give the car to professionals who know how to properly tune the motor.

Here is a short video on the easiest way to replace the valve seals yourself:

Questions and answers:

Do the valves need to be lapped when replacing the caps? It depends on how the replacement is made. If the head is not removed, then it is not necessary. With the cylinder head disassembled and the engine has passed more than 50, then you need to check the condition of the valves.

Can the valve stem seals be replaced without head removal? Such a procedure is possible, but if neither the pistons nor the valves are coked with solid carbon deposits. In order not to remove the head, you need to notice the problem in time.