Timing belt replacement for Lada Kalina

This Russian car belongs to the second group of small cars. Production workers began designing the Lada Kalina in 1993, and in November 2004 it was put into production.

According to a customer survey, this car took fourth place in the popularity rating of cars in Russia. The engines of this model are equipped with a belt-driven valve mechanism, so it will be useful for the owners of this vehicle, as well as for everyone who is interested, to learn how to replace the timing belt with a Lada Kalina 8 valves.

VAZ 21114 engine

This power unit is an injection gasoline engine with a working volume of 1600 cm 3. This is an upgraded version of the VAZ 2111 engine. The cylinder block is cast iron, four cylinders are arranged in a row. The valve train of this engine has eight valves. The injector allowed to significantly improve the dynamics of the car and fuel efficiency. According to its parameters, it complies with Euro-2 standards.

A toothed belt is used in the valve mechanism drive, which somewhat reduces the cost of the power unit, but requires high-quality and timely maintenance of the timing drive. The design of the piston head includes recesses that completely eliminate the possibility of damage to the valve mechanism if the timing belt is damaged or incorrectly installed. Manufacturers guarantee a motor resource of 150 thousand kilometers, in practice it can be more than 250 thousand kilometers.

Replacement procedure

The operation is not a work of particular complexity, no special equipment is required, it may well be carried out by the hands of the owner of the machine. In addition to the standard set of wrenches, you will need a good slotted and flathead screwdriver. Car jack, car bottom support, wheel chocks, wrench for turning the roller on the tensioner.

When replacing, you can use any flat horizontal area on which the machine is installed. The car's operating instructions recommend replacing the belt at a mileage of 50 thousand km, but many owners do this earlier than this period - about 30 thousand km.

Replacing the timing belt Kalina 8-valve will be carried out in the following order:

- On the installed machine, the parking brake is applied, wheel chocks are installed under the rear wheels. Bolts of fastening of the right front wheel are torn off by a balloon wrench

- Using a jack, raise the front of the car on the right side, place a support under the threshold of the body, remove the front wheel from this side.

- Open the engine compartment hood as there will be more work to do.

- To disassemble the timing belt on the timing, it is necessary to remove the protective plastic casing, which is fastened with three turnkey bolts to "10".

- The next step is to remove the belt on the alternator drive. You need a key to "13", which unscrews the tension nut of the generator set, bringing the generator as close as possible to the cylinder block housing. After such actions, the transmission is easily removed from the pulleys.

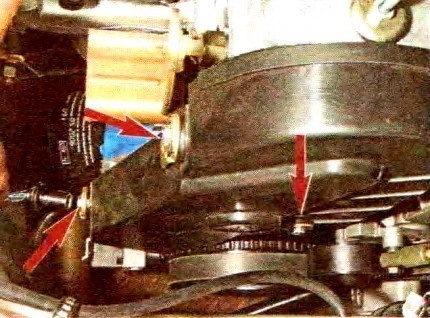

- Now install the timing block according to the marking. You will need a ring wrench or a 17 socket that turns the pulley on the crankshaft until they match.

- To remove the timing belt, it is necessary to block the crankshaft pulley so that it does not rotate. You can ask an assistant to turn on fifth gear and press the brake pedal.

If this does not help, unscrew the plug in the gearbox housing.

Insert the tip of a flathead screwdriver into the hole between the teeth of the flywheel and the gearbox housing, unscrew the bolt securing the pulley to the crankshaft.

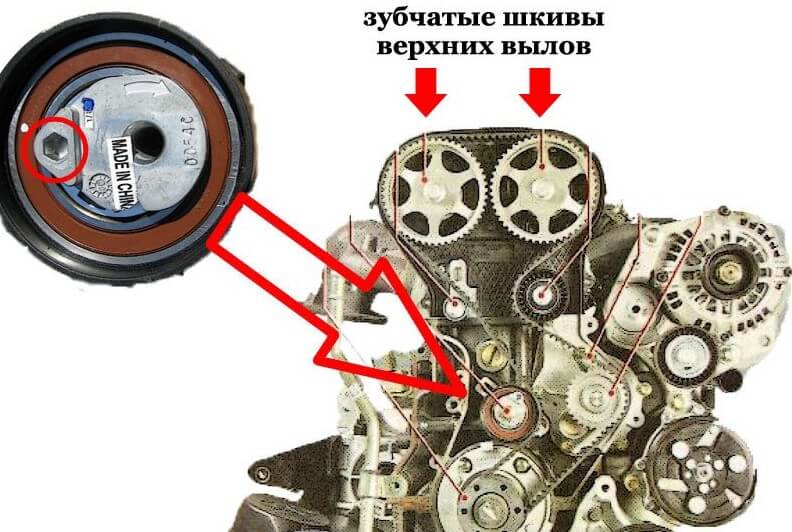

- To remove the belt, release the tension roller. The bolt of its fastening is unscrewed, the roller rotates, the tension weakens, after which the old belt is easily removed. The tension roller is recommended to be changed simultaneously with the drive, which is removed from the block. An adjusting washer is installed at the bottom, which some "clamps" miss.

- Inspect the pulleys on the crankshaft and camshaft, pay attention to wear on their teeth. If such wear is noticeable, the pulleys must be replaced, as the contact area with the belt teeth is reduced, due to which they can be cut.

They also check the technical condition of the water pump, which is also driven by a toothed belt. Basically, a broken belt occurs after the coolant pump seizes. If you are going to change the pump, you will need to drain some of the antifreeze from the engine cooling system.

- Install a new tension roller in its place. Do not forget about the adjusting washer between the cylinder block and the roller, otherwise the belt will move to the side during rotation.

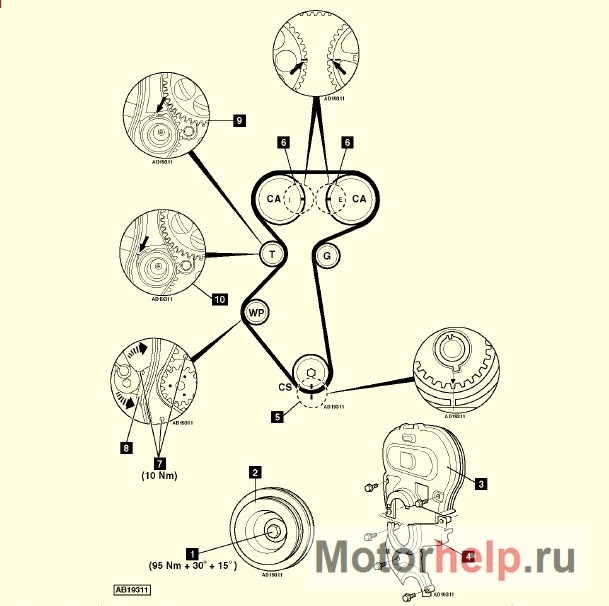

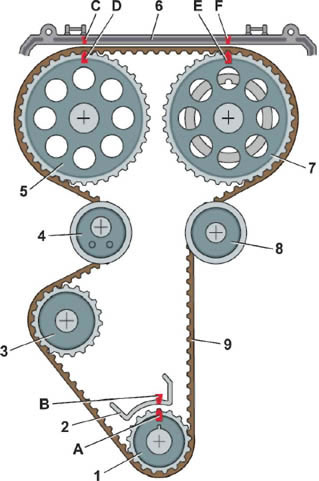

- The installation of a new belt is carried out in the reverse order, but before that, they check once again how much the timing marks match. You need to start the installation from the camshaft pulley, then put it on the crankshaft pulley and the pump pulley. This part of the belt must be tensioned without slack, and the opposite side is tensioned with a tension roller.

- Installing the pulley on the crankshaft again will require it to be fixed in order to avoid possible rotations.

- Then reinstall the protective covers, adjust the generator drive.

At the end of the installation of the timing drive, it is imperative to turn the engine crankshaft a few revolutions, while checking the coincidence of all installation marks.

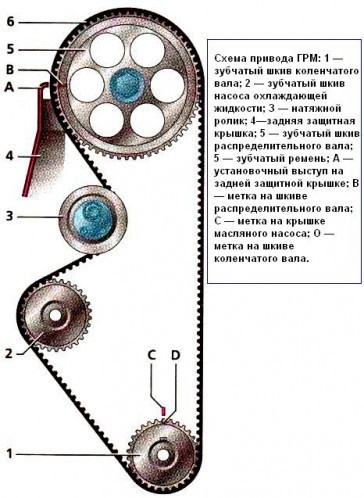

Tagging

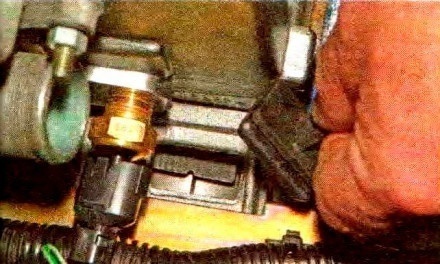

The efficiency of the engine depends on the correct execution of this operation. There are three of them in the engine, which are in the camshaft and rear protective casing, crankshaft pulley and cylinder block, gearbox and flywheel. There is a pin on the camshaft pulley that must align with the kink in the rear timing guard housing. The crankshaft pulley also has a pin that aligns with a slot in the cylinder block. The mark on the flywheel must match the mark on the gearbox housing, these are the most important marks that show that the piston of the first cylinder is at TDC.

Flywheel brand

Correct belt tension

The tension roller is an important part of the gas distribution system on the Lada Kalina. If it is tight, then this will greatly accelerate the wear of the mechanism, with a weak tension, misfires may occur due to belt slippage. The tension is adjusted by turning the tension roller around its axis. To do this, the roller has two holes into which a key is inserted to turn the tensioner. You can also rotate the roller with pliers to remove the retaining rings.

"Craftsmen" do the opposite, use drills or nails of a suitable diameter, which are inserted into the holes. A screwdriver is placed between them, with the handle of which, like a lever, turn the tension roller to the left or right until the desired result is obtained. The correct tension will be in the case when the belt housing between the pulleys can be rotated 90 degrees with your fingers, and after releasing the belt returns to its original state. If this condition is met, tighten the fasteners on the tensioner.

Which belt to buy

The performance of a car engine depends on the quality of the parts used in the drive of the gas distribution mechanism (tension roller, belt). When repairing or maintaining machines, it is desirable to use original parts, but in some cases, non-original spare parts for automotive components have given good results.

The original timing belt 21126–1006040, which is produced by the RTI plant in Balakovo. Experts boldly recommend using parts from Gates, Bosch, Contitech, Optibelt, Dayco. When choosing, you need to be especially careful, because under the brand of well-known manufacturers you can buy a fake.