Replacing silent blocks with a VAZ 2107

Content

Replacing the silent blocks of the VAZ 2107 suspension is not an easy procedure. How often you have to perform it directly depends on the operating conditions of the car, the quality of the parts and the correctness of their installation. Facilitates the work of a special puller, through which most motorists will be able to carry out repairs on their own.

Silent blocks VAZ 2107

On the Internet, the features of replacing the silent blocks of the VAZ 2107 suspension and other cars of the domestic and foreign auto industry are often discussed. The problem is actually relevant and is due to the low quality of our roads. Since the silent block is one of the important elements of the vehicle suspension design, special attention must be paid to its selection and replacement.

What are silent blocks

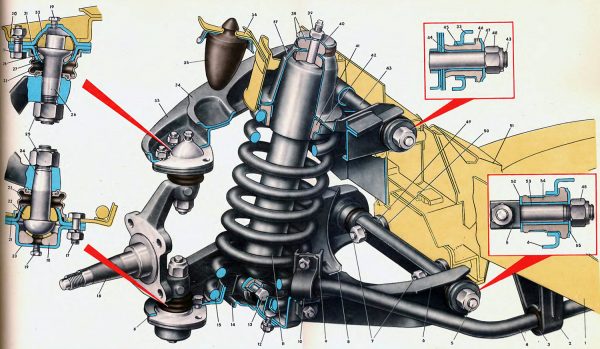

The silent block (hinge) structurally consists of two metal bushings interconnected by a rubber insert. The part is designed to connect the suspension elements, and the presence of rubber allows you to dampen vibrations that are transmitted from one node to another. The silent block must perceive and endure all the deformations that the automobile suspension is subjected to.

Where are they installed

On the VAZ "seven" silent blocks are installed in the front and rear suspension. At the front, levers are attached through this part, and at the rear, jet rods (longitudinal and transverse) connect the bridge to the body. In order for the car's suspension to always be in good condition, and the handling does not deteriorate, you need to monitor the condition of the silent blocks and replace them in a timely manner.

What are silent blocks

In addition to the purpose of silent blocks, you need to know that these products can be made of rubber or polyurethane. It is generally accepted that replacing rubber suspension elements with polyurethane, where possible, will only improve suspension performance and performance.

Silent blocks made of polyurethane are characterized by a longer service life, unlike rubber ones.

The disadvantage of elements made of polyurethane is the high cost - they are about 5 times more expensive than rubber ones. When installing polyurethane products on the VAZ 2107, you can improve the behavior of the car on the road, reduce deformations in the suspension, and also eliminate the so-called squeezing, which is characteristic of rubber elements. This suggests that the suspension will work in the condition provided by the designers at the factory. With the correct selection and installation of parts made of polyurethane, noise, vibration are reduced, shocks are absorbed, which indicates a better performance of such hinges compared to rubber ones.

Reasons for failure

When faced with breakdowns of silent blocks for the first time, it is rather difficult to imagine what can happen to these products after long-term operation. Over time, the rubber begins to tear, as a result of which the hinge needs to be replaced. There can be several reasons for a product to fail:

- High mileage of the car, which resulted in the drying of the rubber, the loss of its elasticity and the appearance of cracks and ruptures.

- Hit on the rubber of the silent block of chemicals. Since the suspension element in question is located near the engine, it is likely that it will be exposed to oil, which leads to the destruction of rubber.

- Incorrect installation. Fixing the bolts of the levers must be carried out only after the car is installed on wheels, and not hung out on a lift. If tightened incorrectly, the silent block rubber twists strongly, which leads to a quick failure of the product.

Checking the status

It will not be superfluous for the owners of the "seven" to know how to determine that the silent blocks need to be replaced. High-quality products go for quite a long time - up to 100 thousand km. However, due to the condition of our roads, the need to replace them usually arises after 50 thousand km. To determine that the rubber hinges have become unusable, you can feel in driving. If the car began to be controlled worse, the steering wheel ceased to be as responsive as before, then this indicates obvious wear on the silent blocks. For greater certainty, it is recommended to visit a service station so that specialists can diagnose the suspension.

The condition of the silent blocks can also be determined independently during a visual inspection. To do this, you will need to drive the car onto a flyover or inspection hole, and then inspect each of the hinges. The rubber part must not have cracks or breaks. One of the signs of failure of silent blocks is a violation of the wheel alignment. In addition, a sign of wear of the part in question is uneven tire tread wear. This phenomenon indicates an incorrectly adjusted camber, which may be the cause of the vehicle's suspension failure.

It is not worth tightening up with the replacement of silent blocks, because over time the seats in the levers break, so it may be necessary to replace the lever assembly.

Video: diagnostics of silent blocks

Replacing the silent blocks of the lower arm

Silent blocks in case of failure, as a rule, cannot be restored, this is due to their design. To carry out work on replacing the rubber-metal hinges of the lower arm on the VAZ 2107, the following tools will be required:

- remover of silent blocks;

- ball joint puller;

- keys for 13, 22, 24;

- a hammer;

- chisel;

- mount;

- lubricant (for example, WD-40).

The procedure for dismantling the lower arm is as follows:

- Raise the car using a lift or jack.

- Take off the wheel.

- Loosen the lower arm axle nuts.

Using a 22 wrench, unscrew the two self-locking nuts on the axis of the lower arm and remove the thrust washers

Using a 22 wrench, unscrew the two self-locking nuts on the axis of the lower arm and remove the thrust washers - Loosen the anti-roll bar mount.

We unscrew the fasteners of the anti-roll bar cushion with a key of 13

We unscrew the fasteners of the anti-roll bar cushion with a key of 13 - Lower the lift or jack.

- Unscrew the nut securing the pin of the lower ball joint, and then press it out by striking with a hammer through a wooden block or using a puller.

We install the fixture and press the ball pin out of the steering knuckle

We install the fixture and press the ball pin out of the steering knuckle - Raise the car and move the stabilizer through the mounting stud.

- Hook the spring and dismantle it from the support bowl.

We hook the rear suspension spring and dismantle it from the support bowl

We hook the rear suspension spring and dismantle it from the support bowl - Unscrew the fasteners of the axis of the lower arm.

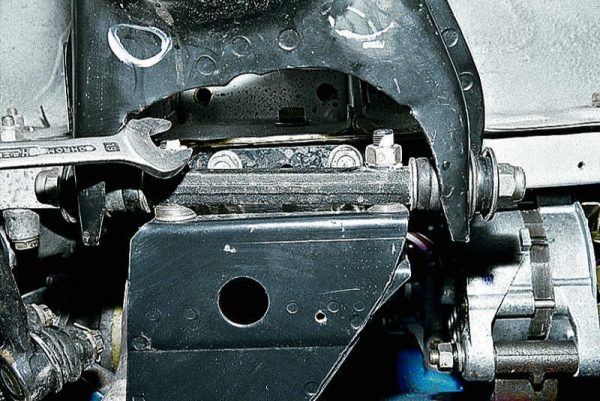

The axis of the lever is attached to the side member with two nuts

The axis of the lever is attached to the side member with two nuts - Remove the thrust washers and dismantle the lever.

After removing the thrust washers, dismantle the lever

After removing the thrust washers, dismantle the lever - If it is planned to replace the lower arm, it will be necessary to remove the lower ball joint, for which the three bolts of its fastening are unscrewed. To replace only silent blocks, the support does not need to be removed.

- Clamp the lever in a vise. The hinges are squeezed out with a puller. If the lever is not damaged, you can immediately start pressing in new parts and assembling the assembly.

To press out the old hinge, we clamp the lever in a vice and use a puller

To press out the old hinge, we clamp the lever in a vice and use a puller

During the assembly process, new nuts should be used to tighten the lever axle and ball pin.

Video: how to replace the silent blocks of the lower arms VAZ 2101-07

Watch this video on YouTube

The same puller is used to remove and install silent blocks. It will only be necessary to change the position of the parts, depending on what operation is supposed (to press in or to press out).

Replacing the upper arm pivots

To replace the silent blocks of the upper arm, you will need the same tools as when repairing the lower elements. The car is lifted in the same way and the wheel is removed. Then the following actions are carried out:

- Loosen the front bumper bracket.

Removing the upper arm begins by unscrewing the front bumper bracket

Removing the upper arm begins by unscrewing the front bumper bracket - Loosen the top ball joint.

Loosen the upper ball joint

Loosen the upper ball joint - The nut of the upper arm axle is unscrewed, for which the axle itself is kept from turning with a key.

We unscrew the nut of the axis of the upper arm, fix the axis itself with a key

We unscrew the nut of the axis of the upper arm, fix the axis itself with a key - Take out the axle.

After unscrewing the nut, remove the bolt and remove the axle

After unscrewing the nut, remove the bolt and remove the axle - Remove the upper arm from the car.

- The old silent blocks are pressed out with a puller, and then the new ones are pressed in.

We press out the old silent blocks and install new ones using a special puller

We press out the old silent blocks and install new ones using a special puller

Replacing silent blocks of jet rods

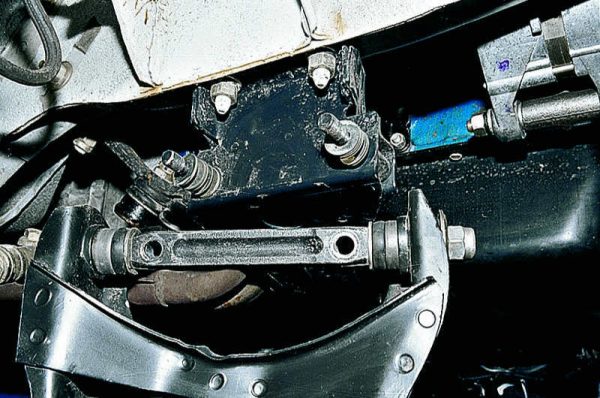

Jet rods are an integral part of the rear suspension of the classic Zhiguli. They are bolted, and rubber bushings are used to reduce loads and compensate for impacts from road irregularities. Over time, these products also become unusable and require replacement. It is best to change them in a complex, and not separately.

Of the tools and materials you will need:

- keys for 19;

- new silent blocks;

- penetrating lubricant;

- metal brush;

- mounting blade.

Let us consider the replacement of jet rod bushings using the example of a long longitudinal rod. The procedure with other suspension elements is carried out in a similar way. The only difference is that in order to dismantle the long rod, it is necessary to remove the lower shock absorber mount. The work consists of the following steps:

- They clean the fasteners from dirt with a brush, treat with a penetrating liquid and wait for a while.

Threaded connection treated with penetrating lubricant

Threaded connection treated with penetrating lubricant - Unscrew the nut with a 19 wrench and remove the bolt.

Unscrew the bushing nut and remove the bolt

Unscrew the bushing nut and remove the bolt - Go to the other side of the rod and unscrew the fastening of the lower part of the shock absorber, removing the bolts and spacer.

To unscrew the fastening of the thrust to the rear axle, remove the lower shock absorber fasteners

To unscrew the fastening of the thrust to the rear axle, remove the lower shock absorber fasteners - Move the shock absorber to the side.

- They clean the fasteners of the jet thrust on the reverse side, moisten with liquid, unscrew and pull out the bolt.

- With the help of a mounting blade, the jet thrust is dismantled.

- To remove the rubber bushings, you need to knock out the inner clip from the metal, for which a suitable adapter is used.

To knock out the bushing, use a suitable tool

To knock out the bushing, use a suitable tool - The remaining rubber in the rod can be knocked out with a hammer or squeezed out in a vice.

The remaining rubber in the rod is knocked out with a hammer or squeezed out in a vice

The remaining rubber in the rod is knocked out with a hammer or squeezed out in a vice - Before installing a new gum, the jet thrust cage is cleaned of rust and dirt.

We clean the bushing seat from rust and dirt

We clean the bushing seat from rust and dirt - A new sleeve is moistened with soapy water and hammered with a hammer or pressed in a vice.

Wet the new bushing with soapy water before installation.

Wet the new bushing with soapy water before installation. - To install a metal sleeve, a device is made in the form of a cone (they take a bolt and grind off the head).

To install a metal sleeve, we make a bolt with a conical head

To install a metal sleeve, we make a bolt with a conical head - The sleeve and fixture are moistened with soapy water and pressed in a vice.

We press the sleeve soaked in soapy water with a vice

We press the sleeve soaked in soapy water with a vice - In order for the bolt to completely come out, use a coupling of a suitable size and squeeze the sleeve.

To install the bolt in place, use a suitable size coupling

To install the bolt in place, use a suitable size coupling

If the inner clip protrudes slightly on one side, it must be trimmed with a hammer.

After replacing the silent block, the thrust is installed in the reverse order, not forgetting to lubricate the bolts, for example, with Litol-24, which will facilitate the dismantling of fasteners in the future.

Video: replacing bushings of jet rods VAZ 2101–07

Watch this video on YouTube

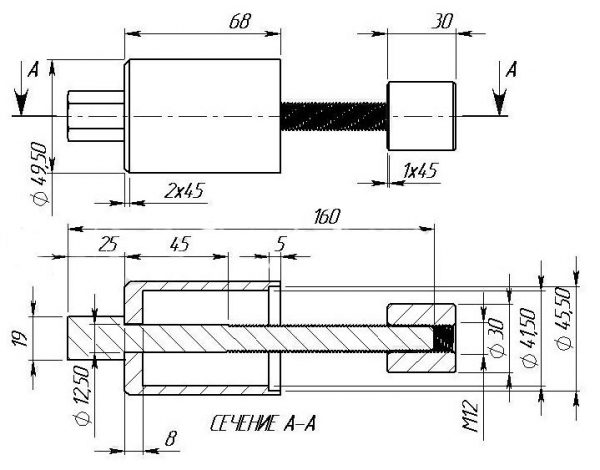

Do-it-yourself puller for silent blocks

The VAZ 2107 hinge puller can be purchased ready-made or do-it-yourself. If there is suitable equipment and materials, it is quite possible for every motorist to make a tool. It is also worth considering that the quality of purchased fixtures today leaves much to be desired. It is possible to replace the rubber-metal joint without special tools, but this will require much more time and effort.

Sequencing

To make a homemade puller, you will need the following:

- a piece of a water pipe 3 cm long with an inner diameter of 40 mm and an outer diameter of 50 mm;

- washer with an outer diameter of at least 50 mm;

- M12 bolt 7 cm long with washers;

- two pieces of pipe 10 cm long and 40 mm in diameter;

- vice;

- a hammer;

- grease.

The main elements of the puller are bushings of different diameters and a bolt with washers and a nut

The main elements of the puller are bushings of different diameters and a bolt with washers and a nut

The manufacturing process of the puller consists of several stages.

- With hammer blows, they make sure that a pipe segment of 40 mm has an inner diameter of 45 mm, that is, they try to rivet it. This will allow the lower arm pivot to pass freely through the pipe.

A piece of pipe with a diameter of 40 mm is riveted to 45 mm

A piece of pipe with a diameter of 40 mm is riveted to 45 mm - Two more pieces are made from a 40 mm pipe - they will be used for mounting new parts.

We make two small blanks from a 40 mm pipe

We make two small blanks from a 40 mm pipe - To press out the old hinges, they take a bolt and put a washer on it, the diameter of which is between the diameters of the inner and outer races.

- The bolt is inserted from the inside of the lever, and a large diameter mandrel is put on the outside. Thus, it will rest against the wall of the lever. Then put on the washer and tighten the nut.

We insert the bolt from the inside of the lever, and outside we put on a large diameter mandrel

We insert the bolt from the inside of the lever, and outside we put on a large diameter mandrel - As it is tightened, the mandrel will rest against the lever, and by means of the bolt and washers, the hinge will begin to be squeezed out.

- To mount a new product, you will need mandrels with a diameter of 40 millimeters. In the center of the eye, a silent block is placed in the lever and a mandrel is pointed at it.

- On the reverse side of the eye, a mandrel of a larger diameter is placed and abutted against the anvil.

- The product is pressed in with a hammer by striking the mandrel.

We press the silent block by hitting the mandrel with a hammer

We press the silent block by hitting the mandrel with a hammer - To remove the silent blocks from the lower arms, install a large adapter, then place the washer and tighten the nut. The axis of the lever itself is used as a bolt.

To remove silent blocks from the lower arms, install a large adapter and tighten it with a nut, laying a washer inside

To remove silent blocks from the lower arms, install a large adapter and tighten it with a nut, laying a washer inside - If the hinge cannot be torn off, they hit the side of the lever with a hammer and try to pull the rubber-metal product out of place, after which they tighten the nut.

- Before installing new parts, the landing site of the lever and axle is cleaned with sandpaper and lightly greased. Through the eyes, the axis of the lever is brought in and new hinges are inserted, after which mandrels of small diameter are set on both sides and first one and then the other part is pressed with a hammer.

We start the lever axis through the eyes and insert new hinges

We start the lever axis through the eyes and insert new hinges

In order to confidently and trouble-free drive a car, it is necessary to carry out periodic inspection and repair of the chassis. Wear of silent blocks affects driving safety, as well as tire wear. To replace damaged hinges, you will need to prepare the necessary tools and perform repairs in accordance with step-by-step instructions.