Replacing the clutch VAZ 2107

The VAZ 2107 clutch is the most important part of the transmission involved in the transmission of torque to the wheels. It is located between the gearbox and the power unit, transmitting rotation from the engine to the box. Knowledge of the design features of the entire assembly and its constituent elements will make it easy to replace the clutch with your own hands if necessary.

Clutch device VAZ 2107

The clutch is controlled by a pedal in the cabin. When pressed, the clutch is disengaged from the gearbox, when released, it is engaged. This ensures a smooth start of the machine from a standstill and silent gear changes. The node itself consists of a large number of elements interacting with each other. VAZ 2107 is equipped with a single-plate clutch with a central spring.

Clutch basket

The clutch consists of two discs and a release bearing. The clutch used on the VAZ 2107 is simple and reliable. The pressure (drive disk) is mounted on the flywheel. Inside the basket there is a driven disk connected to the input shaft of the gearbox with special grooves.

Disc drive inside the basket

Disc drive inside the basket

The clutch can be single-disk and multi-disk. The first is considered more reliable. The clutch works as follows. When you depress the pedal, the release bearing mounted on the input shaft pulls the basket petals against the cylinder block. As a result, the basket and the driven disk are separated and you can change the speed.

For VAZ 2107, discs from VAZ 2103 (for engines up to 1,5 liters) and VAZ 2121 (for engines up to 1,7 liters) are suitable. Outwardly, they are very similar and have a diameter of 200 mm. These discs can be distinguished by the width of the pads (29 and 35 mm, respectively) and the presence of a 6 mm mark in one of the grooves of the VAZ 2121 shock absorber.

Read about the diagnosis of an elastic coupling: https://bumper.guru/klassicheskie-modeli-vaz/zadnij-most/zamena-podvesnogo-podshipnika-na-vaz-2107.html

Clutch disc

The driven disk is sometimes called a drum. On both sides, the pads are glued. To increase elasticity, special grooves are made on the disc during the manufacturing process. In addition, the drum is equipped with eight springs located in the plane of the disc. These springs reduce the frequency of torsional vibrations and reduce dynamic loads.

The drum is connected to the gearbox, and the basket is connected to the motor. During movement, they are strongly pressed against each other, turning in one direction.

The drum is equipped with eight springs located in the plane of the disk

The single-drive scheme used on the VAZ 2107 is reliable, relatively inexpensive and easy to maintain. This clutch is easy to remove and repair.

The driven disk for a 1,5-liter engine has dimensions of 200x140 mm. It can also be installed on VAZ 2103, 2106. Sometimes a drum from Niva (VAZ 2107) is installed on the VAZ 2121, which differs in size (200x130 mm), a reinforced damping system and a large number of rivets.

Release bearing

The release bearing, being the most vulnerable element of the clutch, turns the rotation transmission on and off. It is located in the middle of the disc and is rigidly connected to the pedal through the fork. Each time you press the clutch pedal, the bearing is loaded and its life is reduced. Do not hold the pedal unnecessarily. The bearing is installed in the gearbox drive shaft guide.

The release bearing is the most vulnerable clutch element.

In the clutch kit, the release bearing is designated 2101. The bearing from the VAZ 2121, designed for heavy loads and with an increased resource, is also suitable. However, in this case, the basket will also need to be replaced, since it will take a lot of effort to press the pedal.

Clutch fork

The fork is designed to disengage the clutch when the clutch pedal is depressed. It moves the release bearing and, as a result, the inner edge of the spring.

The fork is designed to disengage the clutch when you press the pedal

In most cases, with a faulty fork, disengaging the clutch becomes impossible. However, sometimes it still crashes. If you don't replace the fork right away, you will need to replace the entire clutch assembly in the future.

Choice of grip

When buying a new clutch kit for a VAZ 2107, experts recommend adhering to the following criteria. When evaluating a driven disk:

- the surface of the lining must be smooth and even, without scratches, cracks and chips;

- all rivets on the disk must be of the same size and at the same distance from each other;

- there should be no oil stains on the disc;

- there should be no play at the junction of the liners and springs;

- The manufacturer's logo must somehow be placed on the product.

When choosing a basket, you should pay attention to the following points:

- the body must be stamped, without cuts and scratches;

- the surface of the disk should be smooth and even, without cracks and chips;

- Rivets must be uniform and strong.

The following brands are the most popular.

- Valeo (France), specializing in the production of high-quality elements of the brake system. The characteristic features of the Valeo clutch are smooth operation with a clear ignition timing, reliability, and a long service life (more than 150 thousand kilometers). However, such a clutch is not cheap.

Valeo clutch features smooth operation with precise engagement

Valeo clutch features smooth operation with precise engagement - Luke (Germany). Luk clutch quality is close to Valeo, but costs a little less. The good damping properties of Luk products are highlighted.

- Kraft (Germany). However, production is concentrated in Turkey. The Craft clutch features smooth operation without overheating and reliable flywheel protection.

- Saks (Germany). The company specializes in the production of transmission parts. The use of asbestos-free coatings in the manufacture of clutch discs has made Sachs very popular in Russia.

The choice of clutch must be approached comprehensively and the choice must be made after inspecting the product and consulting a specialist.

Replacing the clutch

If the clutch begins to slip, it must be replaced. It is more convenient to do this in an elevator or overpass. In extreme cases, you can use a jack with mandatory protective bumpers. To replace you will need:

- standard set of screwdrivers and wrenches;

- pliers;

- clean rag;

- install;

- anima

Dismantling the gearbox

When replacing the clutch on a VAZ 2107, the gearbox cannot be completely removed, but only moved so that the input shaft disengages from the basket. However, most often the box is completely disassembled. In addition to convenience, this allows you to check the condition of the crankcase and oil seals. The gearbox is disassembled as follows:

- Starter removed.

Before disassembling the gearbox, the starter is removed

Before disassembling the gearbox, the starter is removed - Disconnect the shift lever. Before dismantling the gearbox, the gear lever is disconnected

- Silencer brackets are removed.

- Remove the bottom cross bars.

When removing the gearbox, the cross members are disconnected

When removing the gearbox, the cross members are disconnected

More about the VAZ 2107 checkpoint: https://bumper.guru/klassicheskie-modeli-vaz/kpp/kpp-vaz-2107–5-stupka-ustroystvo.html

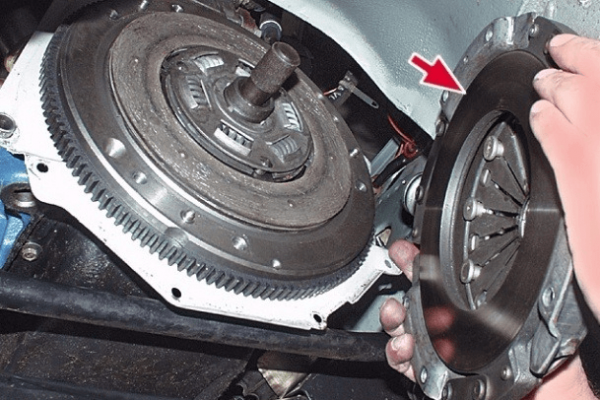

Removing the disc basket

After disassembling the gearbox, the disc basket is removed in the following order.

- The steering wheel is secured against displacement by a mount.

- Using a 13 key, unscrew the fastening screws of the basket

To remove the basket with a key of 13, the bolts of its fastening are unscrewed.

To remove the basket with a key of 13, the bolts of its fastening are unscrewed. - The basket with the mount moves away, and the disc is carefully removed.

- The basket is pressed in a little, then leveled and pulled out.

Removing the release bearing

After the basket, the release bearing is removed. This is done in the following way.

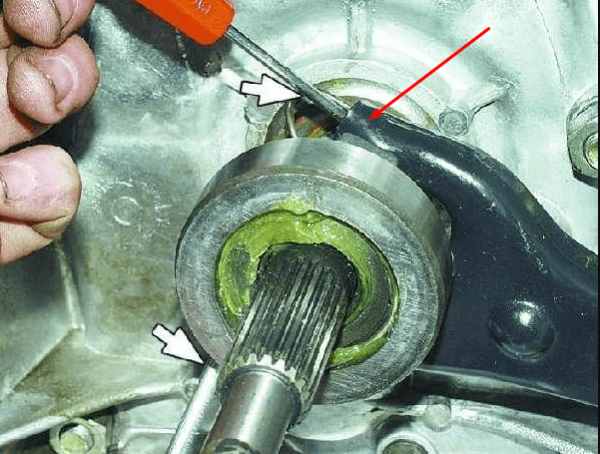

- Use a screwdriver to push the tabs on the fork that engages with the bearing.

To remove the release bearing, it is necessary to press the fork of the antennae

To remove the release bearing, it is necessary to press the fork of the antennae - The bearing is carefully pulled towards itself along the splines of the input shaft.

To remove the bearing, pull it towards you along the axis

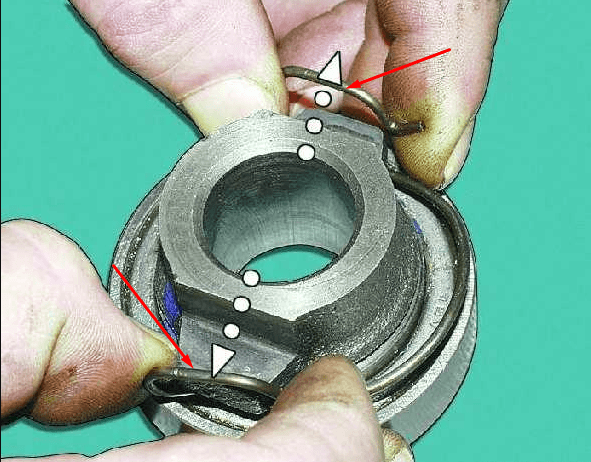

To remove the bearing, pull it towards you along the axis - After removing the bearing, disconnect the ends of the retaining ring from its attachment to the fork.

- The release bearing is attached to the fork with a retaining ring.

After removal, the retaining ring is checked for damage and, if necessary, replaced with a new one. If the ring, unlike the bearing, is in good condition, it can be reused with a new bearing.

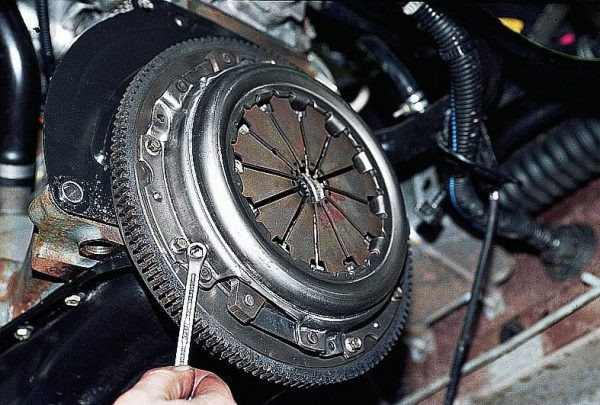

Installing the disc cage

With the clutch and gearbox removed, the condition of all open components and parts is usually checked. The mirrors of the disks and the flywheel should be lubricated with a degreaser, and SHRUS-4 grease should be applied to the shaft splines. When installing the basket, pay attention to the following points.

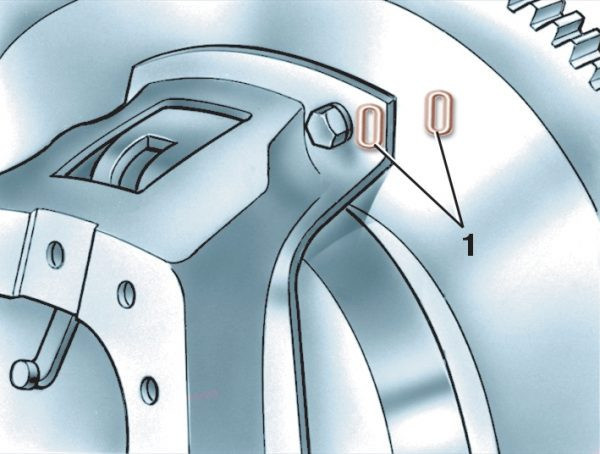

- When installing the basket on the flywheel, align the centering holes in the housing with the pins in the flywheel.

- When installing the basket, the centering holes in the housing must line up with the bolts on the flywheel.

- Mounting bolts should be tightened evenly around the circle, no more than one turn per pass. The tightening torque of the bolts must be between 19,1 and 30,9 Nm. The basket is fixed correctly if the mandrel can be easily removed after installation.

When installing a disc, it is inserted into the basket with the protruding part.

The disc is placed in the basket with the protruding part

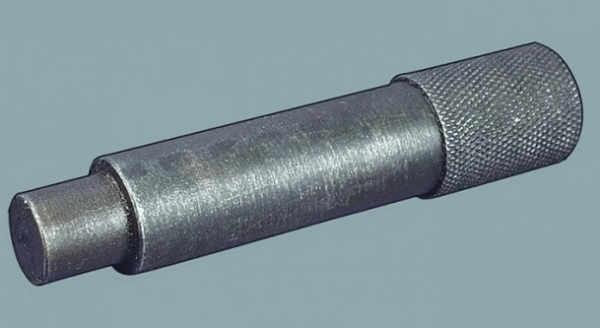

When installing the disk, a special mandrel is used to center it, holding the disk in the desired position.

A special mandrel is used to center the disc

The procedure for installing the cage with a disc is as follows.

- A mandrel is inserted into the hole in the flywheel.

- A mandrel is inserted into the flywheel hole to center the disc

- A new driven disk is installed.

- The basket is installed, the bolts are primed.

- The bolts are tightened evenly and gradually in a circle.

Installing the release bearing

When installing a new release bearing, proceed as follows.

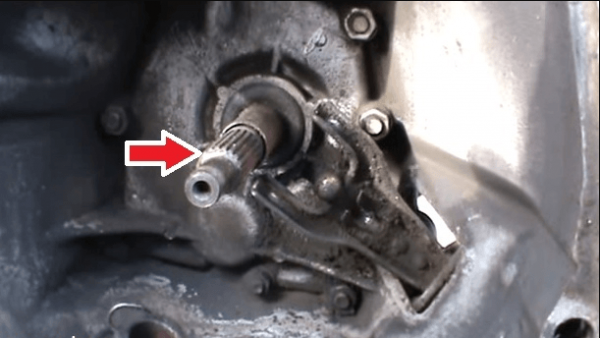

- Litol-24 grease is applied to the splined surface of the input shaft.

The splined part of the input shaft is lubricated with "Litol-24"

The splined part of the input shaft is lubricated with "Litol-24" - The bearing is put on the shaft with one hand, the clutch fork is adjusted with the other hand.

- The bearing is inserted as far as it will go until it locks onto the fork antennas.

A properly installed release bearing will move the clutch fork when pressed by hand.

Installing the checkpoint

Before installing the gearbox, you need to remove the cartridge and move the crankcase towards the engine. Then:

- The bottom bolts are tight.

- The front suspension arm is installed in its place.

- Tightening is done with a torque wrench.

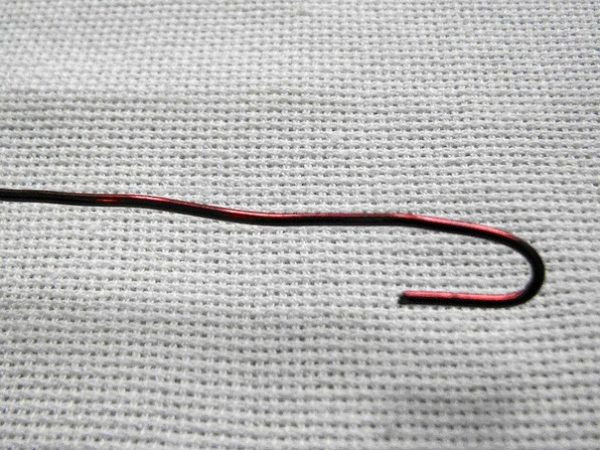

Installing the clutch fork

The fork must fit under the retaining spring on the release bearing hub. When installing, it is recommended to use a hook bent at the end by no more than 5 mm. With this tool, it is easy to pry the fork from above and direct its movement to the installation under the release bearing retaining ring. As a result, the fork legs should be between this ring and the hub.

Homemade wire suspension will help install the clutch fork

Read how to adjust the VAZ-2107 wheel bearing: https://bumper.guru/klassicheskie-modeli-vaz/hodovaya-chast/zamena-stupichnogo-podshipnika-vaz-2107.html

Replacing the clutch hose

A worn or damaged clutch hose will cause fluid to leak from the hydraulic system, making shifting difficult. It is very easy to replace it.

- All fluid is drained from the hydraulic clutch system.

- The expansion tank is detached and retracted to the side.

- With keys 13 and 17, unscrew the connecting nut of the clutch line on the rubber hose.

- The union nut is unscrewed with keys 13 and 17

- The bracket is removed from the bracket and the end of the hose is pulled out.

- With a 17 key, the hose clamp is unscrewed from the working cylinder under the car. The hose is completely removable.

- Installing a new hose is done in reverse order.

- New fluid is poured into the clutch reservoir, then the hydraulic actuator is pumped.

A damaged or worn clutch hose can be identified by the following signs.

- When you fully press the clutch pedal, the car starts to shake.

- The clutch pedal does not return to its original position after being pressed.

- There are traces of fluid on the ends of the clutch hose.

- After parking, a wet spot or a small puddle forms under the machine.

Therefore, replacing the clutch on a VAZ 2107 car is quite simple. This will require a new clutch kit, a standard set of tools and constant adherence to the instructions of professionals.

Valeo clutch features smooth operation with precise engagement

Valeo clutch features smooth operation with precise engagement Before disassembling the gearbox, the starter is removed

Before disassembling the gearbox, the starter is removed When removing the gearbox, the cross members are disconnected

When removing the gearbox, the cross members are disconnected To remove the basket with a key of 13, the bolts of its fastening are unscrewed.

To remove the basket with a key of 13, the bolts of its fastening are unscrewed. To remove the release bearing, it is necessary to press the fork of the antennae

To remove the release bearing, it is necessary to press the fork of the antennae To remove the bearing, pull it towards you along the axis

To remove the bearing, pull it towards you along the axis

The splined part of the input shaft is lubricated with "Litol-24"

The splined part of the input shaft is lubricated with "Litol-24"