Replacing brake pads on a motorcycle

Explanations and practical advice on motorcycle care

Practical guide to self-removal and replacement of brake pads

Whether you are a heavy roller or not, a heavy brake or not, there will inevitably come a time when the need to replace brake pads arises. Wear really depends on the bike, your riding style and many parameters. Hence, there is no typical travel frequency. The best solution is to regularly check the degree of wear of the pads and, without hesitation, change the pads so as not to damage the brake disc (s) and, above all, to maintain or even improve the characteristics of the said braking.

Check the condition of the pads regularly.

The controls are very simple. If the calipers have a cover, it must first be removed in order to have access to the pads. The principle is the same as for tires. There is a groove along the height of the pads. When this groove is no longer visible, the pads must be replaced.

When to do this, don't panic! The operation is relatively straightforward. Let's go for a practical guide!

Check and buy suitable pads

Before heading to this workshop, make sure you check which pads you need to change in order to buy the right brake pads. Here you will find all the tips for different types of brake pads, the more expensive, not necessarily better, or even what you've heard.

Did you find a suitable link for brake pads? It's time to collect!

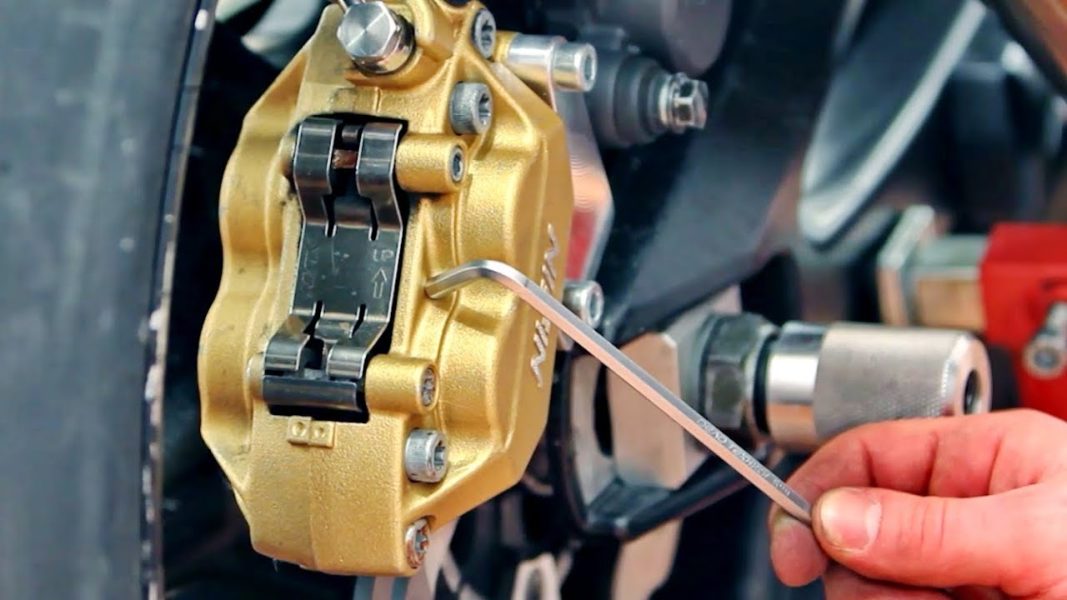

Disassemble acting brake pads

We'll have to dismantle those that are. Keep them close at hand after removal, they can still be used, in particular, to fully insert the pistons back into their seats using a few pliers. Remember to protect the caliper body and push straight: the piston is angled and there is guaranteed leakage. Then it will be necessary to replace the caliper seals, and here is a completely different story. Much longer.

By the way, do not forget that due to the wear of the pads, the level of the brake fluid in its reservoir has dropped. If you have recently topped up the fluid level, it may happen that you cannot then bring them to the maximum ... You know what you need to do: take a closer look.

Another point: either you work without removing the caliper on the base of the fork, or, for greater freedom of movement and visibility, you remove it. We invite you to continue working with the caliper disconnected, this allows you to better push the pistons back if necessary. This can be done a posteriori if there are serious difficulties in installing new pads in place (too thick pads or too much seizing / elongation of the piston). To remove the brake caliper, simply unscrew the two bolts that secure it to the fork.

There are many stirrups, but the base is the same. Typically, the plates are held in place by one or two rods that serve as their guiding pivot for optimal glide. A part that can be cleaned or replaced depending on the degree of wear (groove). Count from 2 to 10 euros depending on the model.

These rods are also called pins. They press the pads against the support under tension and limit their play (impacts) as much as possible. These plates act like a spring. They have a meaning, to find good, the wrong ones are sometimes hard to find.

In general, you should not be afraid of the scattering of small details. This is already the case. However, it may happen that access to the pins of the "rod" is limited. They are either screwed on or embedded and held in place ... with a pin. We've already seen the first cache protecting their location. Once removed, which is sometimes tricky ... just unscrew them or remove the pin in place (again, but classic this time). It is recommended to use pliers or a thin screwdriver to remove it.

Platelets also matter. They are even sometimes differentiated between internal and external. Remember to restore everything on the plate. Small metal grille and trim between them.

It serves as a sound and heat shield. It is also the thickness that is sometimes cursed when the pads are very thick ... Wait to see if reassembly goes well and if there is enough clearance to go through the disc.

Clean up the details

- Clean the inside of the caliper with brake cleaner or a toothbrush and soapy water.

- Check the condition of the pistons. They shouldn't be too dirty or rusty.

- Check the condition of the seals (no leaks or obvious deformation) if you can clearly see them.

- Push the pistons fully back using the old pads, simply replacing them (if possible).

Insert new pads

- Place the new, assembled pads

- Replace pins and spring plate.

- Spread the pads as far as possible along the edges of the calipers to pass the disc. Be careful to arrive parallel to the disc so as not to damage the pad when replacing the caliper.

- Reinstall the calipers by tightening them to the correct torque.

Brake fluid

- Check the brake fluid level in the reservoir.

- Bleed the brake lever several times to restore pressure and order.

Be careful when driving for the first time after changing pads: break-in is compulsory. If they are already in effect most of the time, they should not be overheated. It is also possible that the strength and grip of the pads to the disc will not be the same as before. Be careful, but if everything went well, don't worry, it slows down!

Tools: brake cleaner, screwdriver and bit set, pliers.