Rigid flywheel instead of dual-mass - is it worth it?

Content

A dual-mass flywheel is one of those elements that not only cause a lot of problems for diesel owners, but also bring considerable costs. Even if the wheel itself costs PLN 1000, replacing it, and at the same time replacing the clutch, can double this amount. Then the question arises: is it possible to abandon the double mass and get rid of the problem once and for all?

This is a huge dilemma and the answer to this question is ambiguous, because the elimination of the dual-mass flywheel brings not only benefits. To better understand the problem, please read the text below.

What is a dual mass wheel for?

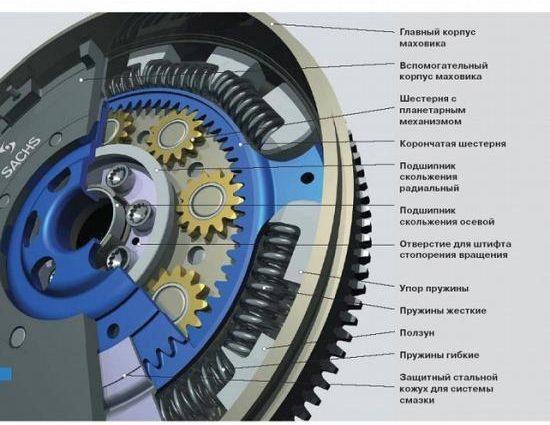

Simplifying the topic the dual mass flywheel supports the mufflers located on the clutch disc (in the form of springs) in a smooth transmission of torque to the gearbox and in damping vibrations, especially those that occur at low speeds. Therefore, it is at least impractical to abandon the dual-mass flywheel and replace it with a rigid one.

This is at least the case for low-torque engines and, for example, naturally aspirated petrol engines, so that their maximum torque is reached relatively late. However, when it comes to a supercharged diesel or gasoline engine, using a rigid wheel instead of a dual-mass one is a big mistake.

This is only allowed in motorsport, because the reduction in driving comfort does not matter, and the gearboxes are replaced with high-performance, more durable ones. Expect the following side effects on a road car:

- deterioration of driving comfort at low speeds - vibrations of the whole car

- big vibration at idle

- more noise

- obvious jerks when pressing or releasing the gas pedal

- less precise shifting

- less wear resistance of the gearbox

- reduced clutch disc life

- lower wear resistance of engine and gearbox mounts

However, there is a way to replace the dual-mass flywheel with a rigid one, which significantly reduces its negative consequences.

Special kits that convert a double mass into a single one.

Of course, you can replace the dual mass flywheel with a rigid one, provided you find one (another version of the same engine) and take the above consequences into account. This is not unreasonable at all, because in an old machine where only expenses are taken into account, this may make sense. Will the box fall apart? If a used wheel costs PLN 500 and a dual-mass flywheel costs PLN 900, the bill is simple.

However, clutch manufacturers anticipated this behavior of users of older cars and brought them to the market a few years ago. replacement kits. The kit includes:

- rigid flywheel replacing the dual-mass flywheel

- Specially prepared clutch disc with larger springs (dampers), long travel and durability

- stronger pressure.

The special design of dampers in the clutch disc, somewhat reminiscent of the principle of operation of a two-mass wheel, largely replaces the operation of a two-mass wheel. One of the pioneers in implementing this type of solution did a study. First of all, it was necessary to check the durability of the clutch and gearbox. It turned out that the transmission, which worked with a mass flywheel, was not affected. The second attempt was a road test of a car model that the test group of drivers used on a daily basis. Their task was to determine which of the two identical machines has double the mass, and which does not. Of course, as one would expect, the answers were not unambiguous.

As a result of the tests, deterioration of only three properties of the car was observed. Specifically, we are talking about a slightly less accurate operation of the gearbox, more vibration and noise. Whereas the durability of the entire clutch as well as the flywheel turned out to be much higher.

Is it profitable to switch from a two-mass wheel to a single-mass wheel?

If we are talking about a transformation like the one described above, then this is not at all an easy answer. Dual-mass to single-mass wheel replacement kits are not cheap, as they also include a stiffer and more complex wheel, and therefore a more expensive clutch disc. For a popular German model car with a diesel engine, such a kit - depending on the manufacturer - costs from PLN 800 to even PLN 1200. Interestingly, for the same car model, a two-mass set of wheels with a clutch costs between PLN 1000 and PLN 1300. So this is not the difference that we will feel immediately when replacing.

To really feel the economic effect, the difference should be much larger, or we have to drive so much that it becomes necessary to replace the dual-mass flywheel again. The practice of workshops shows that dual-mass wheels wear out during mileage, similar to the wear of clutch discs when converted into a single-mass wheel. However, replacing the disc itself, even if it costs more than a standard one, is cheaper than replacing a dual-mass flywheel, for which it is always recommended to also replace the clutch. Thus, savings will appear only after driving approximately 100 km. km or more. So conversion is not for everyone and we will not feel the economic effect as quickly as when installing LPG, i.e. from the first refueling.

Before you make the right decision, you just need to check the prices of the kits. And sometimes it turns out that we can only afford the conversion. In the case of a popular Japanese SUV, a single-mass wheel conversion kit costs between PLN 650 and PLN 1200 depending on the manufacturer. On the other hand, a two-mass set of wheels with a clutch costs between PLN 1800 and PLN 2800. This is a difference of more than PLN 1000, which can be saved on the first exchange. In addition, this model is known for accelerated wear of the dual-mass wheel, often after 60-80 thousand. km with unprepared driving. Does transformation make sense here? Of course. Even if the gearbox wears out after a long run, a used one costs about PLN 1000-1200.