Box adaptation Dsg 7

Content

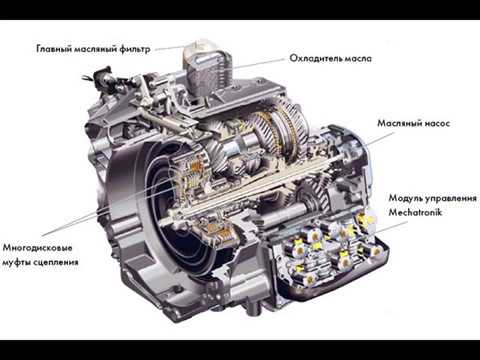

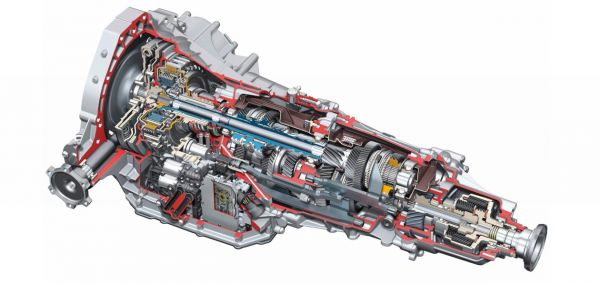

Volkswagen's 7-speed DQ200 preselective transmissions use dry-type clutches that wear out over time. Periodic adaptation of the DSG 7 makes it possible to compensate for changes in the operating clearance between discs in friction clutches. Adjustment is carried out automatically or manually based on the results of computer diagnostics, the number of corrections performed is entered into the controller's memory.

Why adaptation is needed

If jerks or vibrations appear during acceleration of a car equipped with an automatic transmission DQ200, it is necessary to check the condition of the clutch discs and the stroke of the levers that control the clutches. When assembling the transmission, the manufacturer adjusts the parameters, but as wear increases, the gaps will increase and the relative position of the elements will be disturbed. The controller carries out adaptations in automatic mode, which allows compensating for excessive clearances in the drives, restoring the normal operation of the unit.

The box uses open-type clutches, the mechatronics unit corrects the compression of the discs depending on the intensity of acceleration and the amount of transmitted torque. During sudden acceleration, the control rod extends to the maximum distance.

The manufacturer puts the range of the rod stroke into the program, but with excessive wear of the linings, the thrust does not provide compression of the friction discs, which leads to slipping of the clutch. The phenomenon of slipping can also occur due to deformation or overheating of the lining material.

In addition to automatic, manual adaptation is possible, which is carried out after repair work related to the replacement of clutch components or when reprogramming the control unit. The procedure is required when using a remanufactured gearbox instead of the original unit. The adaptation process involves adjusting the gaps in the clutch and mechatronics unit, after which a test run is carried out.

Gearbox diagnostics

To carry out diagnostics, you will need a VAG-COM cable or a similar VASYA-Diagnost cable that works with the application of the same name. The check is carried out every 15000 km, which allows you to assess the condition of the transmission.

After connecting the cable and running the diagnostic utility, you need to go to section 02, which allows you to check the software version. The modification is indicated in the Component field (4 digits located on the right), in order to ensure reliable operation of the transmission, it is necessary to update the firmware version.

Then you need to go to the measurement block (button Meas. Blocks - 08), which allows you to evaluate the residual thickness of the friction linings and strokes of the control rods. To determine the reserve, it is necessary to calculate the difference between the parameters Clutch adaptation AGK Closed and Clutch adaptation Position 3. When using a new clutch, the value is in the range of 5-6,5 mm, if after repair the interval is less than 2 mm, then it is necessary to check the correct installation.

Take measurements of the movement of the rods on the move with smooth and sharp acceleration. Groups 091 and 111 are used to display the parameters, allowing you to evaluate the characteristics of 1 and 2 clutches, respectively. Coupling wear must not exceed 7 mm (field Cluth Actual Position). The Grapf button allows you to display a graph of the functioning of the couplings. After testing the mechanical part of the box, it is required to check the temperature regime. The results are displayed in groups 99 and 102 for the primary clutch disc and 119 and 122 for the secondary clutch elements.

The maximum lining temperature is indicated in groups 98 and 118 (rightmost column). Groups 56-58 allow you to view the number of errors during the operation of the mechatronics, if there were no problems, then the number 65535 is displayed in the fields. Additional groups 180 and 200 are designed to determine the number of adaptations performed, a separate field shows the mileage of the gearbox.

The design of the box predetermines an increased number of adaptations of the secondary clutch. The ratio of the number of adaptations of the first clutch to the second must not exceed 0,33. If the parameter differs upwards, then this indicates abnormal operation of the box and constant attempts by the mechatronics to find the correct position of the disks and rods. After the software upgrade carried out at the beginning of 2018, a ratio of about 1 has become standard (in practice, the even-speed clutch adapts more often than the odd-number clutch).

DSG 7 adaptation

For forced adaptation of the box, 2 methods are used:

- standard, involving the use of a computer;

- simplified, does not require the use of additional equipment.

Standard method

With standard adaptation, a cord is used that is connected to the diagnostic block. The box warms up to a temperature of +30…+100°C, the user can check the value of the parameter through the VASYA-Diagnost program in the "Measurements" section.

The selector is moved to the parking position, the power unit is not turned off. During the adjustment process, it is forbidden to press the accelerator pedal, the machine is held in place by constant pressure on the brake pedal.

The sequence of actions during adaptation:

- After connecting the cord, launch the VASYA-Diagnost program and go to the basic settings section. Additionally, it is recommended to check the temperature of the box by going to section 02 and value group 011.

- Set the control lever to the parking position, additionally fixing the car with a handbrake is not required.

- Stop the engine, then engage the ignition boost circuits.

- In section 02 of the program, find the basic settings menu. Then select parameter 060, which allows you to adjust the clearance values in the clutches. To start the procedure, press the start button, the digital values will change on the screen. When adjusting, extraneous sounds or clicks may be heard from the transmission housing, which is not a sign of a malfunction. The duration of the adjustment procedure is within 25-30 seconds, the time depends on the condition of the nodes and the software version.

- After waiting for the combination of numbers 4-0-0 to appear on the screen, you need to start the engine. Between the end of the calibration procedure and the start of the engine, no more than 10 seconds should elapse. After the start of the power unit, the numbers in the dialog box will begin to change, extraneous sounds may be heard from the transmission housing. The driver is waiting for the end of the adaptation procedure, the display should show the numbers 254-0-0. If a different combination is shown on the screen, then an error occurred during the calibration process, the procedure is repeated again.

- After the adaptation is completed correctly, it is necessary to exit the basic setup mode and check for errors in the DQ200 unit control unit. Found error codes are deleted, then the ignition is turned off. After turning off the test equipment, a test run is carried out according to a special algorithm.

On machines built on the MQB modular platform, the correction algorithm is somewhat different from the above sequence of actions:

- After warming up the power unit and transmission, the machine stops, the engine is turned off and the hand brake is applied.

- When the ignition is switched on, the test computer is connected and the adaptation counter is reset in the basic settings. The procedure takes up to 30 seconds, after the confirmation of the correct execution appears, the ignition is turned off for 5 seconds. Temperature maps are cleared according to a similar scheme with the ignition on and off.

- Then, from the list of functions in the program, you must select the basic installation mode. After the notification of the start of the function appears, you need to press the brake pedal and start the engine. The pedal is held throughout the setup procedure, which takes up to 2-3 minutes. During operation, clicks and extraneous noises are heard from the DQ200 case, after the procedure is completed, a corresponding notification appears on the screen.

- Carry out a test run of the transmission. The manufacturer prohibits any manipulations during the adaptation process, interrupting the process leads to the activation of the emergency mode with loss of mobility. Restoring the performance of the unit is possible only in the service.

Simplified Method

The simplified method does not require the use of a patch cord, the driver resets the control unit.

Before starting the reset, it is required to warm up the engine and gearbox to normal temperature (for example, after driving 10-15 km). Turn off the power unit, and then turn the key in the lock until the dashboard activates. On some machines, the adaptation procedure is performed with the ignition off. The method of the procedure depends on the firmware version and the date of manufacture of the machine, it is recommended to adapt according to both methods.

Lower the door glass, and then sharply press the gas pedal. The kick-down mode should work, resulting in an audible click in the transmission case. The pedal is held down for 30-40 seconds and then released. The key is removed from the ignition lock, after switching on the circuit again and starting the engine, you can start moving. The technique is not suitable for all vehicles with DQ200 transmission.

Test drive after adaptation

To complete the box adaptation procedure, a corrective test drive is carried out, it is required:

- Check the list of errors in the program, detected codes are removed. Then you need to disconnect the diagnostic cables and turn off the engine.

- Start the engine, move the selector to the forward position. Traveling at a slow speed for 20 seconds, using the cruise control function to maintain speed is prohibited.

- Stop the vehicle, engage reverse gear, and then start driving for 20 seconds.

- Brake and move the speed selector to the forward position. Drive forward the distance required to shift all gears. It is forbidden to accelerate sharply, the steps must switch smoothly.

- Move the lever to the manual shift position, and then drive for 1 minute in an even gear (4 or 6). Repeat the procedure, but move at an odd speed (5 or 7). Repeat cycles of movement at even and odd speeds, it is allowed to move in each mode for more than 1 minute. The engine speed is between 2000 and 4500 rpm, cruise control is not allowed.

After the adaptation and test drive, jerks and twitches should disappear. If the problem persists, then it is recommended to update the engine control unit software. On some machines equipped with a BSE engine with a displacement of 1,6 liters, there are problems when switching from 3rd to 2nd speed due to incompatibility of transmission and engine firmware versions. If the owner cannot solve the problem, it is recommended to contact the service for a comprehensive diagnosis of the transmission by specialists who have experience working with DQ200 units.

How often should this be done

The owner of the car carries out forced adaptation when shocks or jerks occur when switching, but before starting the procedure, it is recommended to carry out transmission diagnostics, which will determine the cause of the incorrect operation of the unit.