Powershift gearbox

Content

In all modern production cars, the gearbox plays an important role. There are 3 main types of transmission: manual transmission (mechanical), automatic transmission (automatic) and manual transmission (robotic). The last type is the Powershift box.

What is Powershift

Powershift is a robotic gearbox with 2 clutches, supplied in various variations to the factories of the world's leading automakers.

It has 2 types of clutch basket:

- WD (Wet Dual Clutch) - hydraulically controlled box, wet clutch. It is applied on cars with powerful engines.

- DD (Dry Dual Clutch) - a box with electronic-hydraulic control, a "dry" type clutch. These boxes use 4 times less transmission fluid compared to WD. Are put on vehicles with engines of small and average power.

History of creation

In the early 80s. Porsche's racing car makers were tasked with minimizing downtime when shifting manual transmissions. The efficiency of the automatic transmissions of that time for racing was low, so the company began to develop its own solution.

In 1982, at the Le Mans races, the first 3 places were taken by Porsche 956 cars.

In 1983, this model, the first in the world, was equipped with a manual transmission with 2 clutches. The crews took the first 8 positions at the Le Mans race.

Despite the revolutionary nature of the idea, the level of development of electronics of those years did not allow this transmission to immediately enter the mass-produced car market.

The issue of applying the concept returned in the 2000s. 3 companies at once. Porsche outsourced the development of its PDK (Porsche Doppelkupplung) to ZF. The Volkswagen Group turned to the American manufacturer BorgWarner with a DSG (Direkt Schalt Getriebe).

Ford and other automakers have invested in the development of manual transmissions by Getrag. The latter presented in 2008 a "wet" preselective - a 6-speed Powershift 6DCT450.

In 2010, a project participant, the LuK company, introduced a more compact version - a "dry" box 6DCT250.

What cars are found on

The Powershift version index stands for:

- 6 - 6-speed (total number of gears);

- D - dual (double);

- C - clutch (clutch);

- T - transmission (gearbox), L - longitudinal arrangement;

- 250 - maximum torque, Nm.

Basic models:

- DD 6DCT250 (PS250) - for Renault (Megane, Kangoo, Laguna) and Ford with an engine capacity up to 2,0 liters (Focus 3, C-Max, Fusion, Transit Connect);

- WD 6DCT450 (DPS6 / MPS6) - для Chrysler, Volvo, Ford, Renault и Land Rover;

- WD 6DCT470 — для Mitsubishi Lancer, Galant, Outlander и .;

- DD C635DDCT - for subcompact Dodge, Alfa Romeo and Fiat models;

- WD 7DCL600 - for BMW models with a longitudinal ICE (BMW 3 Series L6 3.0L, V8 4.0L, BMW 5 Series V8 4.4L, BMW Z4 Roadster L6 3.0L);

- WD 7DCL750 — for Ford GT, Ferrari 458/488, California and F12, Mercedes-Benz SLS and Mercedes-AMG GT.

Powershift device

By the principle of its operation, the Powershift box is more similar to a manual transmission, although it conditionally refers to an automatic transmission.

How does work

The gears of the current and subsequent gears are simultaneously engaged. When switching, the clutch of the current gear is opened at the moment the next one is connected.

The process is not felt by the driver. The flow of power from the box to the drive wheels is practically uninterrupted. There is no clutch pedal, control is carried out by an ECU with a group of mechanisms and sensors. The connection between the selector in the cabin and the gearbox itself is carried out by a special cable.

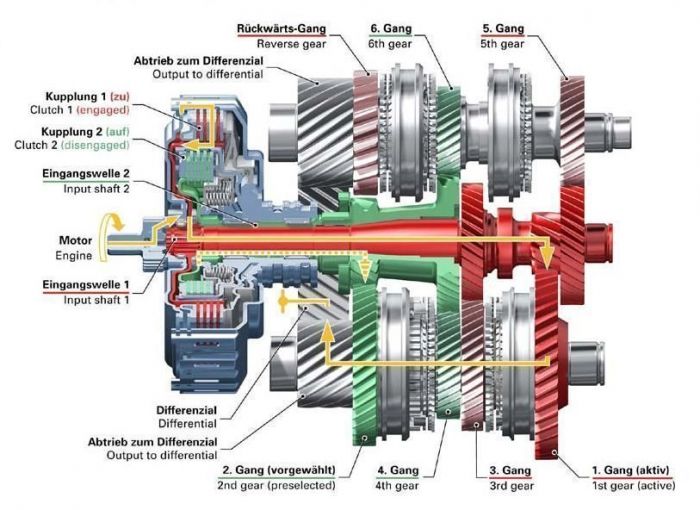

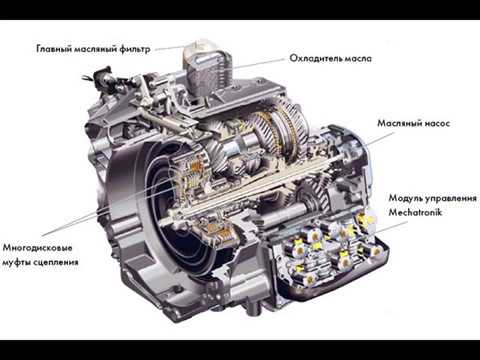

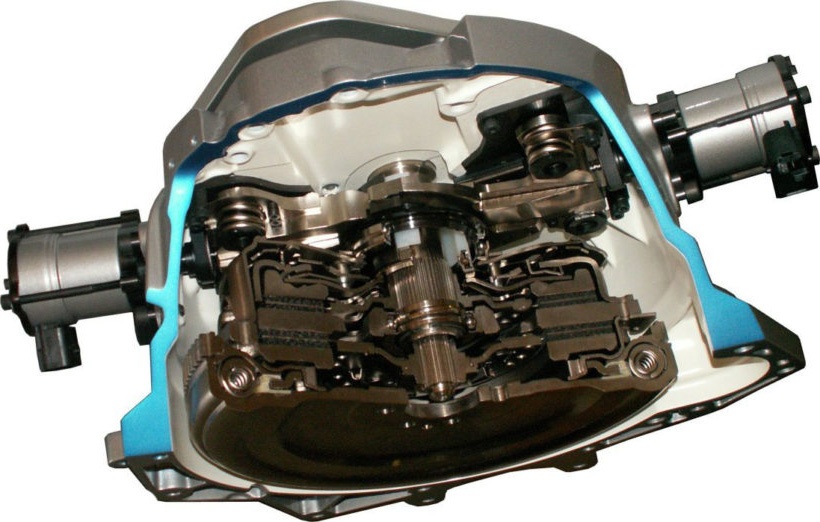

Dual clutch

Technically, these are 2 manual transmissions fused into one body, controlled by an ECU. The design includes 2 drive gears, each rotating with its own clutch, responsible for even and odd gears. In the center of the structure is the primary two-component shaft. Even gears and reverse are switched on from the outer hollow component of the shaft, odd ones - from its central axis.

Getrag says dual-clutch transmission systems are the future. In 2020, the company plans to produce at least 59% of its total gearboxes.

Common Transmission Problems

In order not to bring the Powershift manual transmission to a critical malfunction and, accordingly, a major overhaul, during operation, attention should be paid to the following symptoms:

- When starting from a place, the car twitches, when shifting gears, shocks are felt, as well as when driving in traffic jams. The cause of the malfunction is the failure of the clutch control actuator.

- The transition to the next transmission occurs with a delay.

- There is no possibility of switching on any of the transmissions, there is an extraneous sound.

- Transmission operation is accompanied by increased vibration. This indicates wear on the gears of the shafts and synchronizers of the box.

- The gearbox automatically switches to N mode, the malfunction indicator lights up on the instrument panel, the car refuses to drive without restarting the engine. The cause of the emergency, most likely, is the failure of the release bearing.

- There is a transmission oil leak in the gearbox. This is evidence of wear or misalignment of the oil seals, leading to a decrease in oil level.

- An error indicator lights up on the instrument panel.

- The clutch is slipping. When the engine speed is increased, the vehicle speed does not increase properly. This occurs when the clutch discs fail or oil gets on the disc in DD clutches.

The causes of the listed problems can also be damage to gears, forks, errors in the ECU, etc. Each malfunction must be professionally diagnosed and repaired.

Powershift repair

The Powershift gearbox, built on the principle of a manual transmission, can be repaired in almost any car service. The system has an automatic wear monitoring system.

The most common problem is a leaky seal.

In the event of jamming of the shift forks, it is necessary to replace the assembly assembly, and together with the seals.

Although electronic parts, such as circuit boards and control motors, are repairable, the manufacturer recommends replacing them and, in warranty vehicles, offers a complete replacement.

After repair, the manual transmission should be adapted. There are some peculiarities on a new car and a car with mileage. In most models, this is the calibration:

- gear selector position sensor;

- switching mechanism;

- clutch systems.

Only the calibration of the gear selector position sensor can be called classical. 2 other processes involve learning the ECU without software flashing, during special driving conditions.

Advantages and disadvantages

Gear changes are instantaneous. The acceleration dynamics due to the continuous Powershift traction exceeds the performance of other gearboxes. The absence of power failures has a positive effect on driving comfort, saves fuel (even in comparison with a manual transmission).

The system itself is simpler and cheaper to manufacture than standard automatic transmissions, since there is no planetary gear, torque converter, friction clutches. Mechanical repair of these boxes is easier than repairing a classic machine. With proper operation, the clutch lasts longer than in a manual transmission, since the processes are controlled by precise electronics, and not by the clutch pedal.

But electronics can also be attributed to the disadvantages of Powershift. It is subject to failures and external influences much more than mechanics. For example, if the oil pan protection is missing or damaged, dirt and moisture, if it gets inside the unit, will lead to failure of the ECU circuits.

Even official firmware can lead to malfunctions.

The Powershift manual transmission provides for switching from automatic to manual mode (Select Shift) and vice versa. The driver can upshift and downshift on the go. But to get full control over the checkpoint still does not work. When the speed and engine speed are high, and you want to downshift, for example, from 5th to 3rd immediately, the ECU will not allow the shift to take place and will shift to the most suitable gear.

This feature is introduced to protect the transmission, since downshifting by 2 steps can lead to a sharp increase in rpm before cutoff. The moment of change of speed will be accompanied by a blow, an excessive load. The inclusion of a particular gear will only occur if the range of permissible revolutions and the speed of the car prescribed in the ECU allow this.

How to extend service life

To prolong the life of Powershift, the following rules must be observed:

- The oil in the box must be changed to the one specified by the manufacturer, since any deviations lead to inaccuracies in the operation of the automation.

- When using a manual transmission, it is not recommended to drive off-road, re-gas, pull anything on a trailer, slip, or drive in tightness.

- In the parking lot, you should first switch the selector to position N, pull out the handbrake while holding the brake pedal, and only then switch to P mode. This algorithm will reduce the load on the transmission.

- Before the trip, it is necessary to warm up the car, because the gearbox warms up along with the engine. It is better to drive the initial 10 km of the way in a soft mode.

- It is possible to tow a faulty car only when the selector is in N position. It is advisable to maintain a speed limit of no more than 20 km / h for a distance of up to 20 km.

With careful handling, the operational resource reaches 400000 km for the entire service life of the gearbox.