Adsorber: device and principle of operation

All vehicles that comply with the environmental standard Euro-3 and above are equipped with a gasoline vapor recovery system. You can find out about its availability in the configuration of a particular car by the abbreviation EVAP - Evaporative Emission Control.

EVAP consists of several main elements:

- adsorber or absorber;

- purge valve;

- connecting pipes.

As you know, when fuel comes into contact with atmospheric air, gasoline vapors are formed, which can enter the atmosphere. Evaporation occurs when the fuel in the tank is heated, as well as when atmospheric pressure changes. The task of the EVAP system is to capture these vapors and redirect them to the intake manifold, after which they enter the combustion chambers.

Thus, thanks to the installation of this system with one shot, two important issues are immediately solved: environmental protection and economical fuel consumption. Our today's article on Vodi.su will be devoted to the central element of EVAP - the adsorber.

Устройство

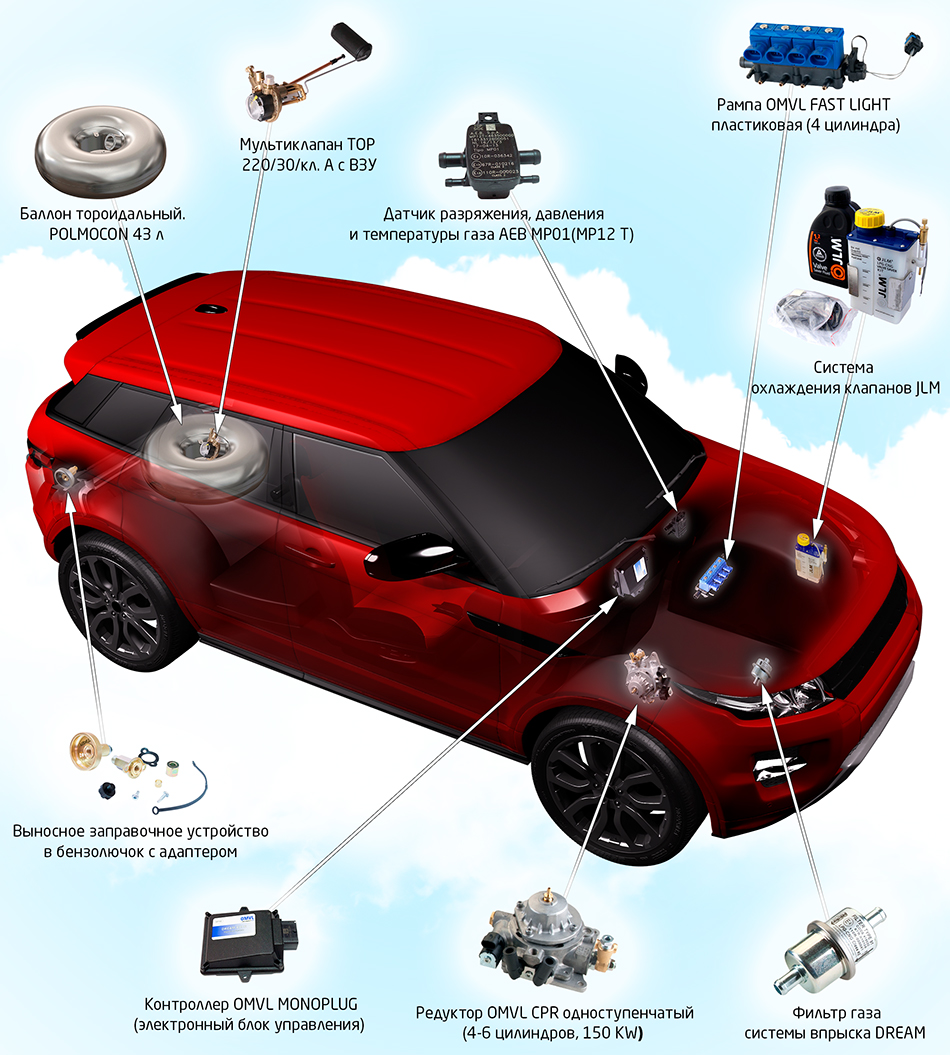

The adsorber is an integral part of the fuel system of a modern car. Using a system of pipes, it is connected to the tank, intake manifold and atmosphere. The adsorber is located mainly in the engine compartment under the air intake near the right wheel arch along the vehicle.

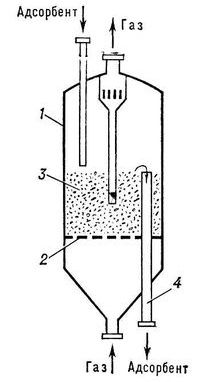

An adsorber is a small cylindrical container filled with an adsorbent, that is, a substance that absorbs gasoline vapors.

As an adsorbent use:

- a porous substance based on natural carbons, simply speaking coal;

- porous minerals found in the natural environment;

- dried silica gel;

- aluminosilicates in combination with sodium or calcium salts.

Inside there is a special plate - a separator, dividing the cylinder into two equal parts. It is needed to retain vapors.

Other structural elements are:

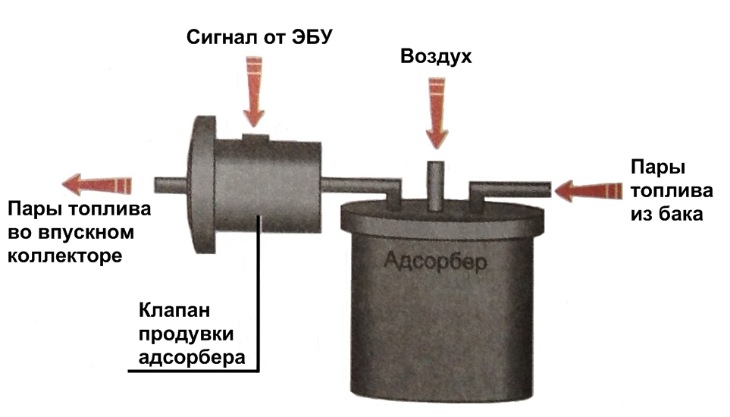

- solenoid valve - it is regulated by an electronic control unit and is responsible for various modes of operation of the device;

- outgoing pipes that connect the tank to the tank, intake manifold and air intake;

- gravity valve - practically not used, but thanks to it, in emergency situations, gasoline does not overflow through the tank neck, for example, if the car rolls over.

It should be noted that, in addition to the adsorbent itself, the main element is precisely the solenoid valve, which is responsible for the normal operation of this device, that is, its purge, release from accumulated vapors, their redirection to the throttle valve or back to the tank.

Principle of operation

The main task is to capture gasoline vapors. As you know, before the mass introduction of adsorbers, there was a special air valve in the tank through which fuel vapors entered directly into the air we breathe. To reduce the amount of these vapors, a condenser and a separator were used, where the vapors condensed and flowed back into the tank.

Today, tanks are not equipped with air valves, and all vapors that have not had time to condense enter the adsorber. When the engine is off, they simply accumulate in it. When a critical volume is reached inside, the pressure increases and the bypass valve opens, connecting the container with the tank. Condensate simply flows through the pipeline into the tank.

If you start the car, then the solenoid valve opens and all the vapors begin to flow into the intake manifold and to the throttle valve, where, mixing with atmospheric air from the air intake, they are injected through the injection nozzles directly into the engine cylinders.

Also, thanks to the solenoid valve, a re-purge occurs, as a result of which previously unused vapors are re-blown to the throttle. Thus, during operation, the adsorber is almost completely cleaned.

Troubleshooting and Troubleshooting

The EVAP system operates in an almost uninterrupted intensive mode. Naturally, over time, various malfunctions occur, which are manifested by characteristic symptoms. Firstly, if the conductive tubes are clogged, then the vapors accumulate in the tank itself. When you arrive at a gas station and open the lid, the hissing from the tank just speaks of a similar problem.

If the solenoid valve leaks, vapors can enter the intake manifold uncontrollably, resulting in increased fuel consumption and problems starting the engine on the first try. Also, the motor may simply stall during a stop, for example, at a red light.

Here are some more typical symptoms of malfunctions:

- at idle, clicks of the solenoid valve are clearly audible;

- floating speed when the engine warms up, especially in winter;

- the fuel level sensor gives incorrect data, the level is rapidly changing both in the upper and lower sides;

- deterioration of dynamic performance due to a drop in traction;

- "triple" when shifting to higher gears.

It is also worth starting to worry if there is a persistent smell of gasoline in the cabin or in the hood. This may indicate damage to the conductive tubes and loss of tightness.

You can fix the problem both independently and with the help of professionals from the service station. Do not rush to immediately run to the parts store and look for a suitable type of adsorber. Try to dismantle and disassemble it. For example, some manufacturers install foam rubber filters inside, which eventually turns into dust and clogs the tubes.

The solenoid valve is also adjustable. So, to get rid of the characteristic clicks, you can turn the adjusting screw a little about half a turn, loosening or vice versa tightening it. When the engine is restarted, the clicks should disappear, and the controller will stop giving an error. If desired, the valve can be replaced by yourself, fortunately, it does not cost too much.

Loading…