automatic transmission - automatic transmission

The automatic gearbox (automatic transmission) selects the gear ratio without the participation of the driver - in a fully automatic mode. The purpose of the "automatic" box is the same as that of the "mechanics". Its main function is to accept, convert and transfer the rotational forces of the engine to the driving wheels of the car.

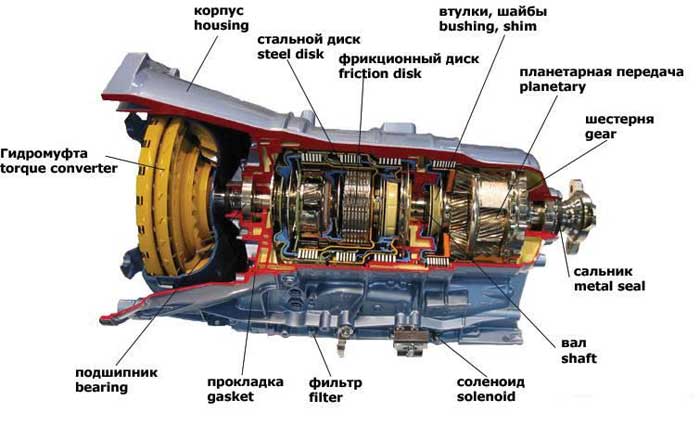

But the "automatic" is much more complicated than the "mechanics". It includes the following nodes:

- torque converter - directly provides the conversion and transmission of the number of revolutions;

- planetary gear mechanism - controls the torque converter;

- hydraulic control system - coordinates the operation of the planetary gear assembly.

According to specialists from Favorit Motors Group of Companies, today the share of sales of cars with automatic transmission in the Moscow region is approximately 80%. Vehicles with automatic transmission require a special approach and attention, although they provide maximum comfort during the ride.

The principle of automatic transmission

The functionality of the "automatic" box is entirely dependent on the torque converter, planetary gearbox and several devices that allow you to control the gearbox assembly. To more fully describe the principle of operation of automatic transmission, you will need to delve into the functionality of each of these mechanisms.

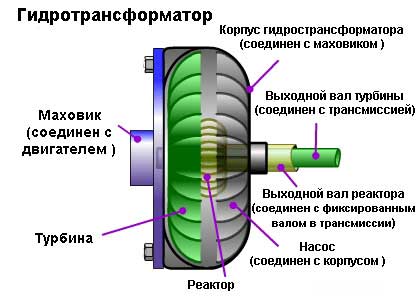

The torque converter transmits torque to the planetary assembly. It performs the functions of both clutch and fluid coupling. Structurally, the planetary mechanism consists of two multi-bladed impellers (pump and turbine wheel), which are located one opposite the other. Both impellers are enclosed in one housing and oil is poured between them.

The turbine wheel is connected to the planetary gear through a shaft. The impeller is rigidly attached to the flywheel. After starting the power unit, the flywheel begins to rotate and drives the pump impeller. Its blades pick up the working fluid and redirect it to the blades of the turbine impeller, causing it to rotate. To prevent oil from returning, a bladed reactor is placed between the two impellers. It adjusts the direction of oil supply and flow density by synchronizing the speed of both impellers. At first, the reactor does not move, but as soon as the speeds of the wheels are equal, it starts to rotate at the same speed. This is the link point.

The gearbox contains the following components:

- planetary devices;

- clutches and brake devices;

- brake elements.

The planetary device has a structure corresponding to its name. It is a gear (“sun”) located inside the “carrier”. Satellites are attached to the “carrier”, during rotation they touch the crown gear. And clutches have the form of discs interspersed with plates. Some of them rotate synchronously with the shaft, and some - in the opposite direction.

The band brake is a plate that covers one of the planetary devices. Its work is coordinated by a hydraulic actuator. The planetary gearbox control system regulates the flow of the working fluid by braking or releasing the elements of rotation, thereby adjusting the load on the wheels.

As you can see, the power of the motor is transmitted through the liquid to the gearbox assembly. Therefore, the quality of the oil plays a crucial role in the operation of automatic transmissions.

Automatic transmission operating modes

Almost all types of automatic transmissions today have the same operating modes as half a century ago, without any major changes.

Automatic transmission is carried out according to the following standards:

- N - includes a neutral position;

- D - forward movement, while depending on the needs of the driver, almost all stages of high-speed modes are used;

- P - parking, used to block the driving wheelset (the blocking installation is located in the box itself and is in no way connected with the parking brake);

- R - reverse movement is turned on;

- L (if equipped) - allows you to shift to a lower gear to increase engine traction when driving in difficult road conditions.

Today, the PRNDL layout is considered to be in common use. It first appeared on Ford cars and has since been used as the most convenient and practical gear changing model on all cars in the world.

On some modern auto transmissions, additional driving modes can also be installed:

- OD - overdrive, characterized by the fact that it reduces fuel consumption in economical driving mode;

- D3 - recommended when driving around the city at medium speeds, since constant "gas-brake" at traffic lights and pedestrian crossings often block the clutches in the torque converter;

- S - mode for using low gears in winter.

Benefits of using AKCP in Russia

The main advantage of cars equipped with an automatic transmission can be considered the convenience of their operation. The driver does not need to be distracted by constant shifting of the lever, as happens in a manual box. In addition, the service life of the power unit itself is significantly increased, because during the operation of the automatic transmission, modes of increased loads are excluded.

The "automatic" box is equally successfully used in equipping cars of different capacities.