Manual transmission - manual gearbox

Content

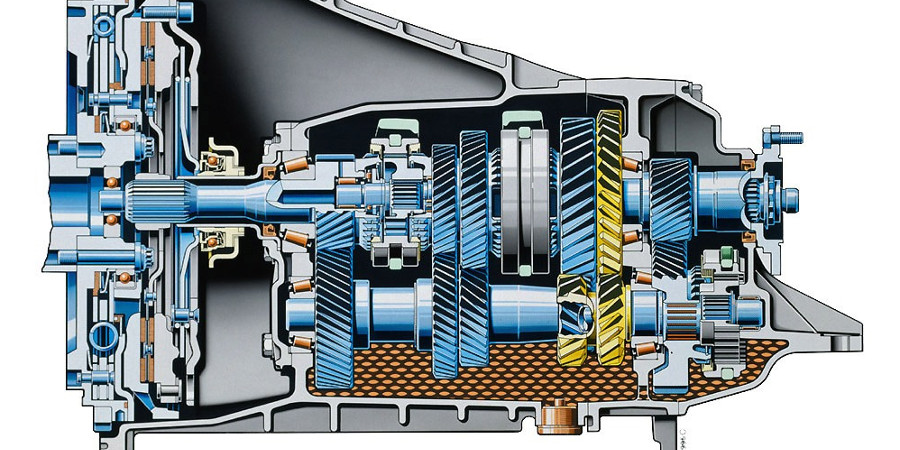

A manual transmission is one of the most important components of a car, its main task is to receive, change and transmit torque from the motor to the wheels. In simple terms, it allows the car's wheels to rotate at different speeds at the same engine speed.

Many motorists may have a reasonable question, but why do we need this mechanism? After all, the speed of the car depends on the force of pressing the accelerator, and, it would seem, you can connect the motor directly to the wheels. But the motor units operate in the range of 800-8000 rpm. And when driving - in an even narrower range of 1500-4000 rpm. Running too long at low RPM (less than 1500) will quickly cause the engine to fail because the oil pressure is insufficient to lubricate. And prolonged operation at too high speeds (over 4000) causes rapid wear of components.

Consider how the gearbox changes the speed of the car:

- the engine rotates the crankshaft and drive shaft during operation;

- this movement is transmitted to the gears of the manual transmission

- gears begin to rotate at different speeds;

- the driver includes the selected gear;

- a given rotation speed is transmitted to the cardan shaft and wheels;

- the car starts to move at the required speed.

In other words, the gearbox is designed to provide the choice of a suitable mode of motor functionality in different conditions on the road - acceleration, braking, smooth driving, and so on. In the "mechanics" the procedure for changing gears is carried out by the driver in manual mode, without the use of auxiliary devices.

The specifics of the manual transmission

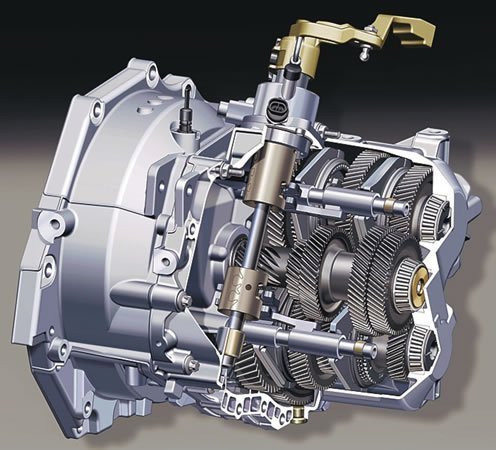

The capabilities of each car with a manual transmission depend on the gear ratio, i.e. on how many gears are available to control the speed of the vehicle. Modern cars are usually equipped with a five-speed manual transmission.

Manual transmissions have been produced for over 100 years, today their design has been brought to almost perfection. They are reliable, economical in maintenance, unpretentious in operation and easily repaired. Perhaps their only drawback is the need to shift gears on their own.

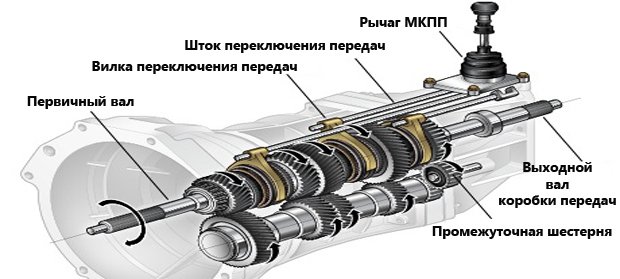

The gearbox works closely with the clutch. When changing gear, the driver must depress the clutch pedal to synchronize the operation of the engine and the shafts that regulate the increase / decrease in speed.

When the driver depresses the clutch and begins to change gear, the shift forks begin to work, which move the clutches in the desired direction for shifting. In this case, the lock (blocking) is immediately activated, which excludes the possibility of simultaneously switching on two gears at once. If the device were not equipped with a lock, then periodically the gear shift forks could cling to two clutches at once.

After the fork has touched the clutch, it gives it the necessary direction. The teeth of the coupling and the transmission gear located next to the shaft are in contact, due to which the gear is blocked. After that, the joint synchronized rotation on the shaft immediately begins, the manual transmission transmits this rotation to the propulsion unit, from it to the cardan shaft and then to the wheels themselves. This whole procedure takes a fraction of a second.

In the same case, if none of the splined couplings interacts with the gear (i.e. does not block it), then the box is in a neutral state. Accordingly, forward movement is impossible, since the power unit and transmission are in a disconnected state.

A manual gearbox is usually equipped with a handy lever, which experts call a “selector”. By pressing the lever in a certain direction, the driver selects an increase or decrease in speed. Traditionally, the gear selector is installed on the box itself in the passenger compartment, or on the side.

Benefits of using manual transmission in Russia

The most important advantage of cars with manual transmission can be considered their cost, in addition, the “mechanics” do not require special cooling, which is usually equipped with automatic transmissions.

Every experienced driver knows well that cars with manual transmission are more economical in fuel consumption. For example, Peugeot 208 Active 1.6 gasoline, manual (115 hp), which is available in the Favorit Motors group of companies, consumes only 5.2 liters of fuel per 100 kilometers in urban conditions. Like this brand, other models of vehicles with manual transmission are currently in demand by those drivers who want to save money on buying fuel without compromising the mode of operation of the car.

The manual transmission has a simple design, so that troubleshooting can be carried out without the use of expensive equipment. Yes, and the repair itself will require significantly less investment from the owner of the car than in the case of troubleshooting in the automatic transmission.

Another advantage of "mechanics" is reliability and durability. The life of a manual transmission is usually equal to the life of the car itself. The high reliability of the box is becoming one of the main reasons why motorists choose cars with manual transmission. However, the specifics of gear shifting will require a relatively frequent replacement of clutch mechanisms, but this is not a very costly procedure.

In emergency situations on the road, a car with a manual transmission has more options and techniques (driving through mud, ice, water). Accordingly, even an inexperienced driver will be able to cope with driving in the absence of a smooth road surface. In case of breakdowns, a vehicle with a manual transmission can be started from acceleration, it is also allowed to transport the car in tow without restrictions on the speed of transportation.

Have you run out of battery or failed starter? It is enough to put a car with "mechanics" into "neutral" and push it, then turn on the third gear - and the car will start! With the "automatic" such a trick can not be done.

Modern manual transmission

Modern manual transmissions have a different number of gears - from four to seven. Experts consider 5 and 6 gears to be an ideal modification, since they provide optimal control of the vehicle's speed.

4-speed gearboxes are obsolete, today they can only be found on used cars. Modern cars develop high speeds, and the “four-step” is not designed for driving at speeds over 120 km / h. Since there are only 4 gears, when driving at high speed, you have to maintain high speeds, which leads to premature engine wear.

The seven-speed manual is reliable and allows full control of the car's dynamics, but it requires too many gear shifts, which can be tiring for the driver in city driving.

Advice from specialists in the operation of manual transmission

Like any other complex vehicle mechanism, a manual transmission must be operated in strict observance of the rules of the vehicle manufacturer. The implementation of these simple rules, as the practice of Favorit Motors specialists shows, can slow down the wear of parts and reduce the frequency of breakdowns in units.

- It is advisable to change gears in accordance with the recommendations of the manufacturers regarding the permitted minimum and maximum speed intended for each gear. In addition, the manufacturer usually provides instructions for economical operation of the vehicle. For example, for a Volkswagen Polo car (engine 1.6, 110 hp, 5 speed manual transmission) there are recommendations for economical fuel consumption: shift to second gear at a speed of 20 km/h, to third gear when reaching 30 km/h, to fourth gear - at 40 km / h and in fifth - at 50 km / h.

- Switching to reverse gear (reverse) should only be done when the vehicle is completely stationary. Even at low speeds, shifting into reverse gear is unacceptable.

- It is recommended to squeeze the clutch pedal quickly, and release it slowly and without jerks. This reduces the friction force on the release bearing and delays the need for repairs.

- When driving on a slippery road (icy ice), do not drop the clutch or put the gearbox in neutral.

- It is not recommended to shift gears during sharp turns, this leads to rapid wear of the mechanisms.

- Any vehicle needs constant monitoring of the amount of oil in the manual transmission crankcase. If, as necessary, the working fluid is not topped up and replaced, the oil becomes saturated with metal dust, which increases wear.

As you can see, it is quite possible to extend the "life" of a mechanical box. To do this, you just need to follow all the recommendations of the manufacturer, and at the first doubts about the quality of work, contact the specialists of the Favorit Motors Group of Companies.

The company's technical centers are equipped with all the necessary diagnostic equipment and narrow-profile tools for diagnosing malfunctions and repairing manual transmissions. To perform repair and restoration work, Favorit Motors Group of Companies specialists use technologies recommended by the manufacturer and high-quality certified spare parts.

Car service masters have many years of experience and specialized knowledge, which allows them to quickly diagnose malfunctions and carry out any kind of repair of manual transmissions. Each specialist regularly undergoes retraining at the training centers of manufacturers and receives a certificate for the right to repair and maintain a certain brand of car.

Favorit Motors car service customers are offered a convenient work schedule, online registration for maintenance and repair, a flexible loyalty program, a guarantee for spare parts and all types of manual transmission repairs. All necessary components and consumables are available in the company's warehouse.

The price of manual transmission repair depends on the type of breakdown and the amount of repair and restoration work required. By contacting Favorit Motors Group of Companies, you can be sure that the performance of the "mechanics" will be restored as soon as possible, and the cost of services will not negatively affect the family or corporate budget.