Shock absorbers and springs - types and properties

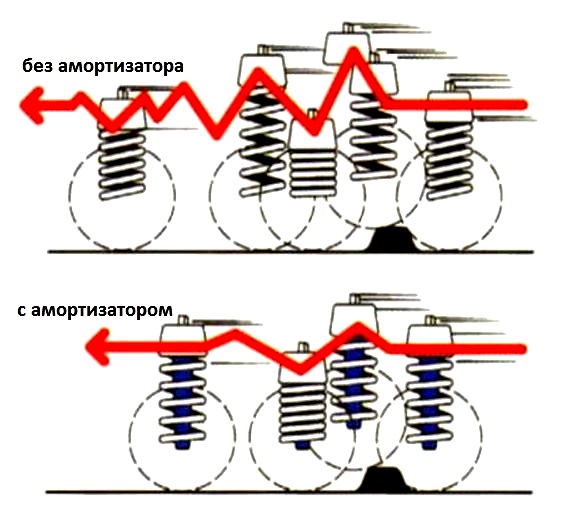

Shock absorbers and springs are extremely important elements of the car's suspension, the primary task of which is its correct springiness. Comfort and, above all, driving safety depend on their reliable operation.

In modern cars, mainly for their intended purpose, various types of shock absorbers and springs are installed. In the case of shock absorbers, this is due to the optimization of the damping of the longitudinal and transverse vibrations that occur during the operation of the suspension system, depending on the type of the vehicle. However, as for the springs, their design parameters correspond to the multi-link systems used in most cars, in which the metal-rubber elements used dampen longitudinal and transverse vibrations. The designs of modern automotive springs, in turn, are adapted to other important requirements, such as: weight reduction or optimization of the luggage compartment or engine compartment.

Single-pipe - but which one?

Currently, the most commonly used single tube shocks are the Gas-A-Just and the optional Ultra SR. The first one used high pressure gas (nitrogen) from 25 to 30 bar. They are standard on some vehicle models, but can also be used as an option on vehicles fitted with twin-tube shock absorbers from the factory. The most important advantage of Gas-A-Just (so-called high pressure) shock absorbers is their durability and greater driving safety, mainly due to more rigid performance in relation to twin-tube shock absorbers (so-called pressure). Therefore, due to the proposed performance parameters, they provide better wheel contact with the road surface and reduce body roll, which translates into better track stabilization.

Ultra SR shock absorbers, on the other hand, have been developed for users who, on the one hand, prefer dynamic and sporty driving, and, on the other hand, value comfort on the road. Optionally, they are installed on individual car models in order to adapt their performance to the nature and style of driving by optimally increasing the gas (nitrogen) pressure. Thanks to this solution, Ultra SR shock absorbers provide better stabilization of the car during sporty driving, which directly affects driving confidence and a sense of safety on the road. Their additional advantage is the ability to use a standard spring: they have a standard height, which does not underestimate the car's suspension.

Fixed or variable diameter?

Two types of springs are installed on the rear axle of cars: with a constant wire diameter (RX type) or with a variable wire diameter (RJ type). Most RX springs are cold rolled from silicon chromium steel. RX springs are characterized by a linear operating characteristic, which means that their deflection occurs evenly along the entire length, i.e. the same for all turns. RJ springs, on the other hand, are made from variable diameter drawn wire, thicker in the middle and thinner at both ends. These springs are formed in a hot torsion process and are made using chrome vanadium steel. Due to their shape, manufacturing process and the type of steel they are made of, RJ springs have progressive performance, which means they deflect gradually from thinner coils to a thicker center. This is of great importance while driving, especially when weighing a car. When loaded with a certain weight, a vehicle equipped with RJ springs will maintain more ground clearance than a vehicle with RX springs. The RJ springs also enhance safety and travel comfort. RX and RJ springs are interchangeable. Replacing RX springs with RJ springs is acceptable provided they are replaced in pairs on the same axle.

How to control?

Inspection points for checking the performance of shock absorbers installed in the car (to a lesser extent springs) use the so-called EUSAMA Method. The test is to force the vertical oscillations above the resonant frequency and then to determine the so-called EUSAMA Index (EU). It is calculated on the basis of data such as: the tire's static pressure on the ground and its minimum dynamic pressure. Based on these parameters, the device determines the percentage of wheel adhesion to the ground. However, the EUSAMA method has one significant drawback: it can be used to assess the technical condition of shock absorbers, but only taking into account a preliminary inspection or possible replacement of worn or damaged chassis elements. The measurement results depend on many conditions, including the condition of the components interacting in the suspension system, proper tire pressure, and the condition and size of the tires.