Asynchronous motor - principle of operation and control features

Content

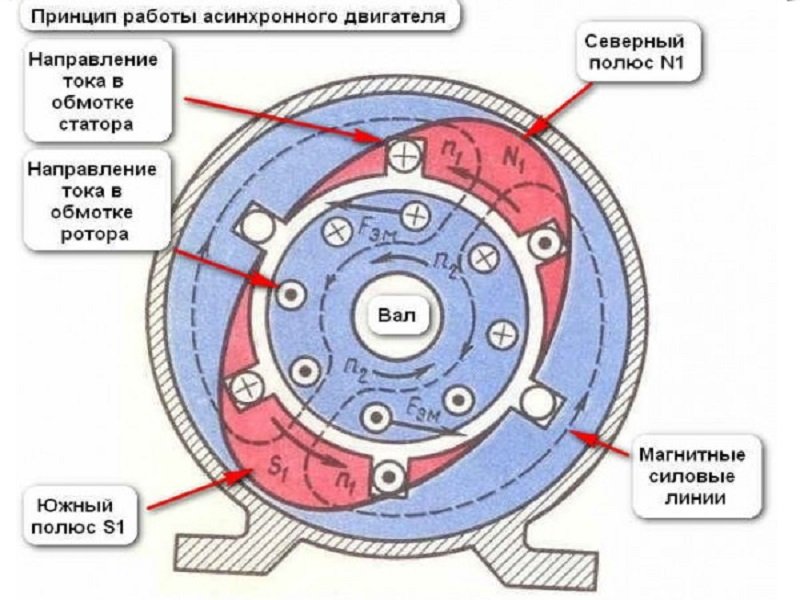

Among all electric motors, the asynchronous motor should be especially noted, the principle of operation of which is based on the interaction of the magnetic fields of the stator with the electric current induced by this field in the rotor winding. A rotating magnetic field is generated by a three-phase alternating current passing through the stator winding, which includes three groups of coils.

Induction motor - working principle and application

The principle of operation of an asynchronous motor is based on the possibility of transferring electrical energy into mechanical work for any technological machine. When crossing the closed winding of the rotor, the magnetic field induces an electric current in it. As a result, the rotating magnetic field of the stator interacts with the currents of the rotor and causes the occurrence of a rotating electromagnetic moment, which sets the rotor in motion.

In addition, the mechanical characteristic of an induction motor is based on its operation in two versions. It can work as a generator or an electric motor. Due to these qualities, it is most often used as a mobile source of electricity, as well as in many technological devices and equipment.

Considering the device of an asynchronous motor, it should be noted its starting elements, consisting of a starting capacitor and a starting winding with increased resistance. They are distinguished by their low cost and simplicity, do not require additional phase-shifting elements. As a disadvantage, it should be noted the weak design of the starting winding, which often fails.

Induction motor device and maintenance rules

The starting circuit of an asynchronous motor can be improved by connecting in series with the starting capacitor winding. After disconnecting the capacitor, all engine characteristics are fully preserved. Very often, the switching circuit of an asynchronous motor has a working winding, divided into two phases connected in series. In this case, the spatial shift of the axes is in the range from 105 to 120 degrees. Motors with shielded poles are used for fan heaters.

Watch this video on YouTube

The device of a three-phase asynchronous motor requires daily inspection, external cleaning and fixing work. Twice a month or more, the engine must be blown from the inside with compressed air. Particular attention should be paid to bearing lubrication, which must be appropriate for the specific type of motor. A complete replacement of the lubricant is carried out twice during the year, with simultaneous flushing of the bearings with gasoline.

The principle of operation of an asynchronous motor - its diagnostics and repair

In order to control the three-phase asynchronous motor conveniently and for a long time, it is necessary to monitor the noise of the bearings during operation. Whistling, crackling or scratching sounds should be avoided, indicating a lack of lubrication, as well as thuds, indicating that clips, balls, separators may be damaged.

In the event of unusual noise or overheating, the bearings must be disassembled and inspected.. The old grease is removed, after which all parts are flushed with gasoline. Before putting new bearings on the shaft, they must be preheated in oil to the desired temperature. The new grease should fill the working volume of the bearing by about one third, evenly distributed over the entire circumference.

Watch this video on YouTube

The condition of the slip rings is to systematically check their surface. If they are affected by rust, the surface is cleaned with soft sandpaper and wiped with kerosene. In special cases, they are bored and polished. Thus, with normal care of the engine, it will be able to serve its warranty period and work much longer.