Wood car. Wood-burning engine.

Content

You don't have to be a driver to notice that fuel prices have risen obscenely fast in recent weeks. It is known that the quantity of this raw material is limited and in the near future there will be problems with its availability. However, few people know that an alternative and very cheap way to power a car was invented at the beginning of the last century.

Human ingenuity knows no bounds, especially in times of crisis. Going back a few pages of history, we learn that in the interwar period, for obvious reasons, there was a fuel crisis. The civilian population, despite being equipped with more and more affordable cars, could not move around in them. From here, more and more interesting ideas appeared than to replace gasoline or diesel fuel. It turned out that the wood is suitable for the production of fuel, namely wood gas, also known as "holkgas".

Theoretically, any spark ignition engine can run on wood gas. This issue also applies to diesel engines, but this requires additional refinement in the form of adding an ignition system. As follows from various experiments carried out at the turn of the decade, the best way to drive a car on this unusual fuel is a water-carbon gas generator, i.e. the so-called carbon monoxide generator. Imbert generator.

This technology was developed in the early 1920s. This complicated terminology probably doesn't mean much to a potential reader, so below is an explanation of how this system works. This solution makes it possible to produce 1 liter of fuel from 2 kg of firewood or 1,5 kg of charcoal. And as you know, the price of this raw material, even in the most optimistic scenario, is at least three times lower than in the case of the final product in the form of gasoline.

How does it work?

In the Imbert boiler, air is fed into the furnace from top to bottom in a flow, so that it passes through burning wood or charcoal. Oxygen in the air combines with carbon to form carbon dioxide. The latter, in turn, reacts with carbon and is reduced to carbon monoxide. At this point, the water vapor that is released from the burning wood, under the influence of a very high temperature, combines with carbon, forming carbon monoxide and hydrogen. Ash accumulates in the ash pan. The gas obtained from under the grate is removed by a pipe directed upwards, which will prevent its contamination with ash.

The gas passes through a special sump, where it undergoes initial purification, and only then enters the cooler. Here the temperature drops and the gas separates from the water. Then it passes through the cork filter and enters the mixer, where it combines with the air coming from the outside after filtering. Only then is gas supplied to the engine.

The temperature of the resulting gas is low, since the Imbert generator uses exothermic reactions, and the moment of reduction of carbon dioxide to oxide is an endothermic reaction, identical to the reaction of steam with coal. To reduce energy losses, the walls of the generator are double. Air entering the generator passes between two layers.

The other side of the coin

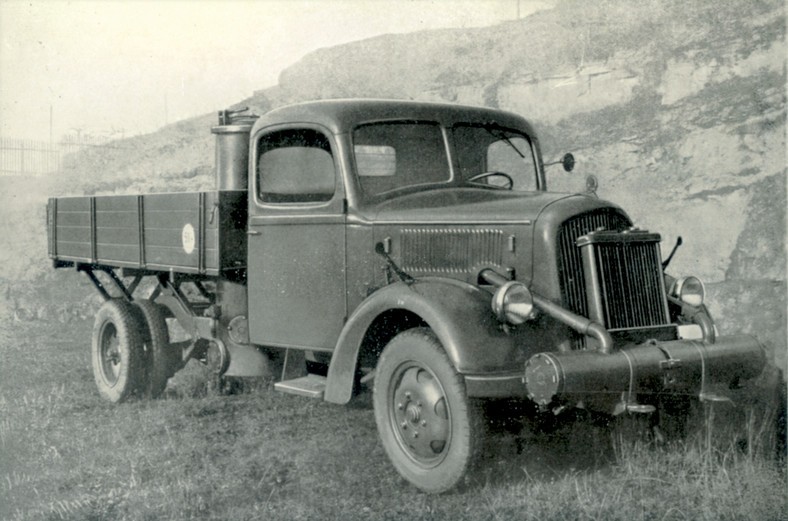

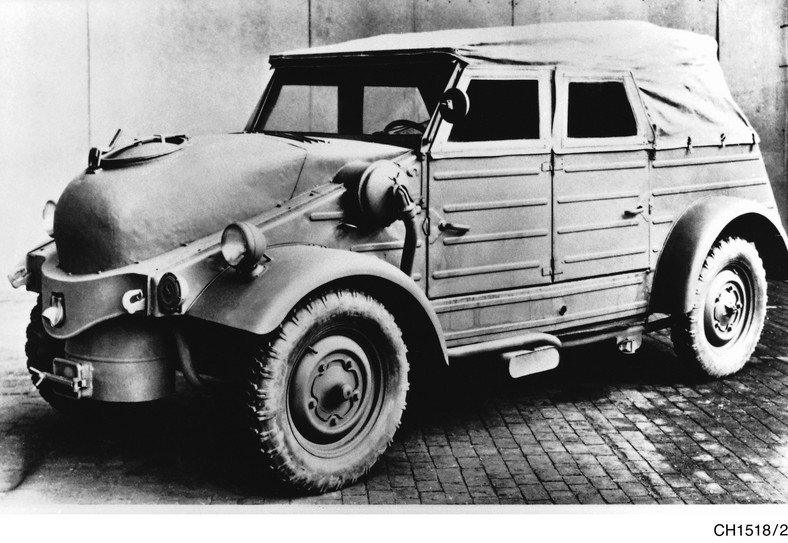

Unfortunately, this solution, although it can significantly reduce operating costs, results in a wood gas engine reaching less power than a gasoline engine. Usually it is about 30 percent. However, this can be compensated by increasing the compression ratio in the unit. The second, more serious question is the size of such a structure. The Imbert generator, due to the reactions taking place in it, is a device of rather large dimensions. Therefore, it was usually "attached" to the outside of the car.

Holcgas is best suited for vehicles with long working hours. This is due to the fact that starting the engine on this fuel takes about 20-30 minutes. That is how long it takes to “ignite” the gas generator. So far, the best places where wood-gas transport could operate are areas with easy access to the tree, where the nearest gas station is several or several tens of kilometers away.

So far, however, despite high fuel prices, we are unlikely to face a fuel crisis. Using charcoal is a good alternative when or in places where fuel is really hard to come by. In the current situation, this invention can only be treated as a curiosity for the time being.

Do-it-yourself wood-burning engine!

Fuel prices have been steadily rising for several months and breaking new limits. Experts warn that in the near future, the problem may lie not only in high prices, but also in the availability of gasoline, diesel or liquefied petroleum gas. So it was before! What are the alternatives to these fuels? Machines can be converted to burn holzgas (wood gas), i.e. generator gas, which can be obtained from wood. How to do it?

Most gasoline engines can be converted to run on wood gas, most easily with carburetors.- Wood is a renewable fuel, which does not mean that such a drive can be considered environmentally friendly.

- A gas generating set is larger and heavier than an LPG set and is also difficult to regulate.

- A serious disadvantage of such a solution is that the installation is not immediately ready for operation, it must be preheated

- Wood gas generators can also produce fuel, for example. for home heating

Remember the song "Locomotive from the announcement" by Perfect?

Gasoline at this price today

That the car is not in your pocket

I will pour water into the locomotive

And it will be cheaper for me to travel

I will pick up trash

I will gather brushwood (…)

I will live like a king!

Who would have thought that a text from 1981 could sound so relevant again? But driving a locomotive is not an option. Since the dawn of the automotive industry, there have been times when petroleum fuel was either extremely expensive or unattainable - and no one wanted to give up driving cars with internal combustion engines. Affordable and cheap alternative to expensive liquid fuel or gas? In the case of heating houses, the matter is obvious - burning everything that comes to hand in stoves, such as wood waste, brushwood.

The cheapest way to drive is brushwood instead of petrol or LPG

Well, you can’t drive a car with brushwood! It? Of course you can, but it's not that easy! The solution is to install so-called holzgas, or wood gas! The idea is not new; designers have been experimenting with such installations for more than 100 years. Installations of this type gained the greatest popularity during the Second World War, when petroleum fuels were almost completely used by the armies, and their reserves were very limited. It was then that civilian vehicles (and some military vehicles) were massively converted so that they could run on generator gas. Also after the war, such installations were popular in some remote parts of the world, especially where firewood was free and liquid fuel was difficult to obtain.

Any gasoline engine can run on wood gas.

Modification of the engine itself (as long as it is a carbureted four-stroke) is the least of the problems - it is enough to apply gas to the intake manifold. Since it does not liquefy, there is no need for heat reducers or other complex devices. The greatest difficulty in this case is the construction and installation in the car of the corresponding "gas generator", that is, a device that is sometimes called a gas generator. What is a gas generator? In simple terms, this is a device that will produce gas in the car, which is then burned in the engine. Yes, this is not a mistake - in cars on the so-called holzgas, fuel is produced on an ongoing basis!

Way to drive cheap - how does a wood gas generator work?

In the car or in the trailer behind the car there is a special, tightly closed boiler with a firebox placed under it. Firewood, shavings, brushwood, sawdust, or even peat or charcoal are thrown into the boiler. A fire is lit in the hearth under a closed cauldron. After some time, after reaching the desired temperature, the heated mixture begins to smoke, "carbonate" - the accumulated gases are discharged outside through a suitable pipe, away from the fire burning in the hearth.

Since combustible materials are heated with minimal access to oxygen, the boiler emits mainly carbon monoxide, i.e. extremely poisonous, but also flammable carbon monoxide. Other components of the gas obtained in this way are primarily the so-called. methane, ethylene and hydrogen. Unfortunately, this gas also contains many non-combustible components, eg. nitrogen, water vapor, carbon dioxide - which means that the fuel has a fairly low calorific value, and the installations are designed in such a way that the gas is not stored in them, but enters the engine on an ongoing basis. The greater the engine's need for fuel, the more powerful the installation is needed.

Riding on Holzgas - it doesn’t get cheaper, but there are problems

In order for the gas to be suitable for powering engines, it still needs to be cooled and filtered from tarry deposits - which additionally forces the installation to be large - and also the gas resulting from the so-called. pyrolysis of wood and other biowaste is not the cleanest fuel. Even with good residual filtration, tar accumulates in the intake manifold, soot accumulates in the combustion chambers and on the spark plugs. An engine running on wood gas has even a few tens of percent less power than gasoline or liquefied gas - in addition, it is better not to use it with “gas to metal”, because in such a situation, if the installation has too low efficiency ( it happens), the engine starts to run too lean, which can lead, for example, to burning valves or burning cylinder head gaskets. But on the other hand, the fuel is free,

The generator produces gas even when the engine is off

Other inconveniences: when we turn off the engine, the generator still produces gas - it can be used, for example, by lighting a special burner built specifically for this purpose, or ... releasing the gas into the atmosphere, because there is no way to store it. Driving with a fire in a car or in a trailer behind a car is also not very safe, and if the installation is not tight, the car's passengers face death. The installation requires painstaking cleaning (depending on the load, every few tens or at most every few hundred kilometers) - but it is unbeatably cheap.

Wood gas generator - for preppers and for cheap home heating

It's easy to find videos online showing how to build a gas generator to power a car with wood gas - some projects have even been designed to be made from commonly available elements, and even a welding machine was not needed for construction. . There is no shortage of enthusiasts converting their cars to such fuel - it is quite popular, for example, in Russia. in the deserted corners of Sweden, but a large group of fans of such systems can be found in Russia and the post-Soviet republics. Some people treat wood gas generators and the engines powered by them like toys and, for example, build lawn mowers that work on this method.

Watch this video on YouTube

In turn, emergency kits (world war, zombie apocalypse, volcanic eruption, natural disaster) are popular among the so-called survivalists to help power generators. There are also companies on the market that offer modern gas generators with appropriate stoves as an environmentally friendly and cheap source of building heating.