Balance shafts of the engine, purpose and device

Content

During the operation of the crank mechanism, inertial forces inevitably arise. They can be divided into balanced and unbalanced. The movement of the pistons generates vibrations and noises. To eliminate the imbalance, the flywheel and crankshaft are completely insufficient. Therefore, manufacturers install balancer shafts.

Purpose of balance shafts

The main function that balance shafts perform is to eliminate imbalance and reduce vibration. This problem has become especially relevant for powerful engines. The development of motors with a volume of more than 2 liters has led to strong vibration. To get rid of this problem, the engineers decided to use balancer shafts.

In this case, the location of the cylinders must be taken into account. Manufacturers use 3 layout schemes.

- Cylinders can be in the same plane.

- A completely different scheme is considered quite common, in which the axes of the cylinders are directed in opposite directions.

- There is a system that provides for the use of a v-shaped scheme.

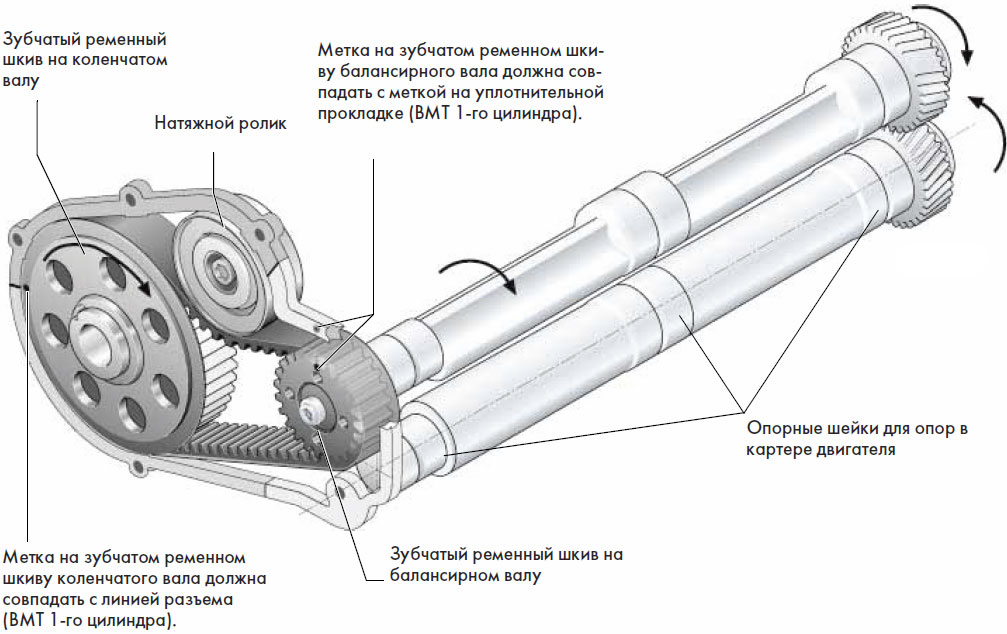

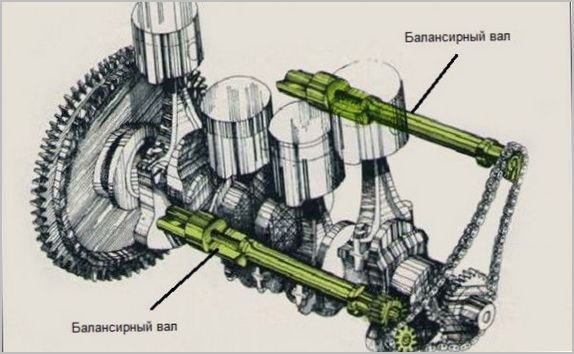

The quality of balancing depends on the layout of the cylinders. To eliminate the imbalance, balance shafts are used, which are cylindrical rods. These elements are installed in 2 pieces on each side of the crankshaft. Gears are used to connect parts. In this way, the system can be balanced. Balance shafts can significantly reduce vibration and noise levels.

Principle of operation

To compensate for the energy, springs are used, which are located in the drive gears. The reason for the increased wear of the nodes may be the additional load associated with the occurrence of malfunctions. The greatest load falls on the plain bearings, which transmit movement from the crankshaft. The car owner is advised to contact the service center, and not fix the faults on their own.

Drive types

The balancing system is driven by a chain or toothed belt. Shaft vibrations can be reduced in this way. In addition, manufacturers install a spring damper in the drive.

When were balance shafts invented?

The idea of introducing balance shafts belongs to Mitsubishi. The novelty was first used in 1976. The technical development became very popular as it allowed to reduce vibrations and noise. With the help of balancer shafts, it was possible to increase the engine resource. At this time, powerful engines began to be produced, which had a volume of 2 liters. However, during operation there was a strong vibration. In the future, other manufacturers decided to use the development.

Features of replacing balance shafts

The loads that occur during operation have a negative effect on the bearings. Replacing this node is too expensive. To save money, car owners are forced to dismantle the shaft block. Plugs are used to protect threaded connections during the repair process. In the absence of balance shafts, engine operation is disrupted. Vibrations and noise appear in the power plant. The degree of imbalance directly depends on the technical characteristics of the engine. You can balance the system by using balancer shafts. To do this, it is necessary to change the design of the engine. However, this decision may affect the duration of the motor.

The reason for the appearance of extraneous sounds may be a malfunction of components and assemblies. Therefore, the car owner should immediately contact the service center. Lack of repair can lead to serious trouble. Increased noise may be due to the failure of the shaft assembly or a broken belt. Noise and vibration can occur due to worn bearings. Malfunctions affect the operation of the entire engine.

To eliminate defects, it is necessary to replace the balancing shafts. For this purpose, car owners have to contact the service center. The prospect of a major overhaul is unlikely to appeal to motorists. Therefore, it is necessary to identify the causes of vibration and noise in a timely manner. To protect the holes from mechanical damage, experts use plugs. The absence of compensators can cause imbalance of the motor. In this case, car owners are forced to agree to the complete dismantling of the unit. Unprofessional actions can lead to loss of engine performance.

The cause of extraneous noise in the power plant may be the failure of parts. Therefore, motorists must adhere to the following rules:

- Aggressive driving style can be the cause of component wear.

- To reduce the load on the gears of the shafts, it is necessary to service the system in a timely manner.

- The car owner must change the oil in a timely manner.

- If necessary, the belt or drive chain may need to be replaced. The balance shafts must rotate without additional loads.