How does a knock sensor work in an engine, its design

Content

Normal operation of an automobile engine is rarely possible if the process of combustion of fuel in its cylinders is disturbed. In order for the fuel to burn properly, it must be of suitable quality, and the ignition timing of the engine must be set correctly. Only under these conditions, the engine does not waste fuel and can operate at full capacity. If at least one condition is absent, the probability of detonation is not excluded. An automotive knock sensor helps prevent this phenomenon.

Detonation combustion, what is it

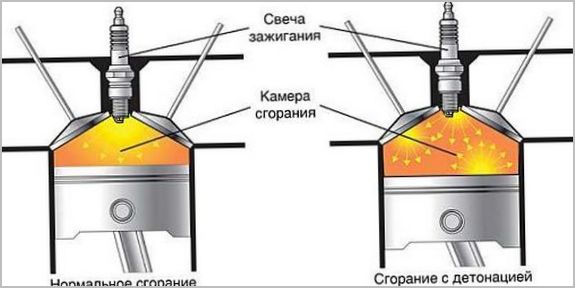

Detonation of the air-fuel mixture in the engine is called an uncontrolled combustion process, the result of which is a "mini-explosion". If the combustion of fuel occurs in normal mode, the flame moves at a speed of approximately 30 m/s. If detonation occurs, the flame speed increases sharply and can reach 2000 m / s, which leads to an increase in load and accelerated wear of pistons and cylinders. As a result, if the car is not equipped with a knock sensor, it may need major repairs after only 5-6 thousand kilometers traveled.

What causes detonation

The most common causes of fuel detonation are:

- poor quality and octane number of gasoline: the lower the octane number, the worse the resistance to detonation;

- imperfect engine design: detonation can be facilitated by structural features of the combustion chamber, fuel compression forces, poor layout of spark plugs, and much more;

- unfavorable conditions under which the engine operates: load, general wear, the presence of soot.

How does a knock sensor work?

The knock sensor operates on the principle of correcting the ignition timing to a value at which controlled combustion of the air-fuel mixture is restored. The sensor is used on injection-type automotive engines.

In the process of fuel detonation, the engine begins to vibrate strongly. The sensor determines the appearance of detonation precisely by capturing vibrations, which are then converted into an electrical signal.

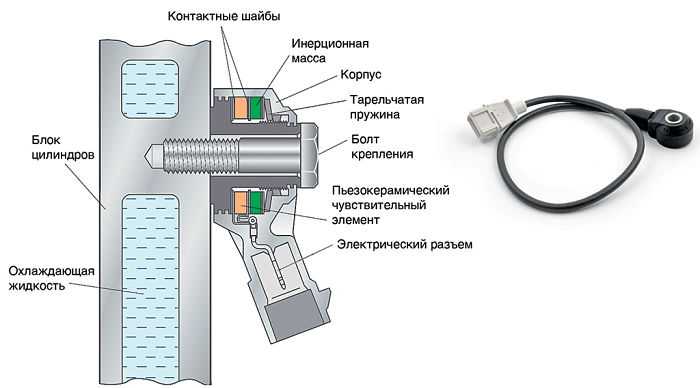

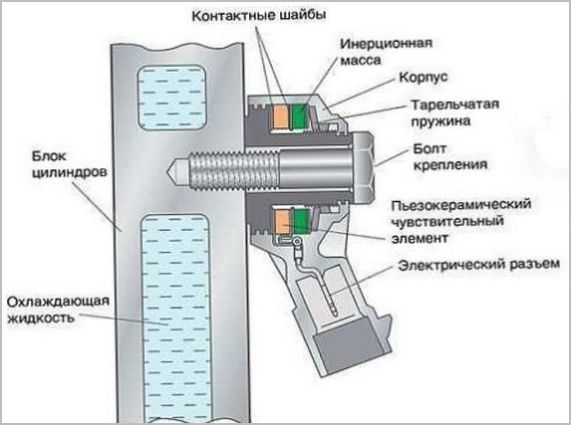

The main components of the sensor are:

- piezoceramic sensing element;

- resistor;

- insulator;

- steel weight.

From the piezoceramic element, wires go to the contacts and the steel weight. A resistor that regulates the strength of the electrical impulse is located at the output. The element that directly perceives the vibration is a weight - it exerts pressure on the piezoelectric element.

The usual location of the knock sensor is on the motor housing, between the second and third cylinders. The sensor does not respond to all vibrations, but only to abnormal ones, that is, in the frequency range from 30 to 75 Hz.

The choice of such a location of the sensor is due to the fact that it is most favorable for adjusting the operation of each cylinder and is located near the most frequent detonation epicenters.

When vibration is detected by the sensor, the following occurs:

- the piezoelectric element transforms the energy of vibration into electricity, which increases with the amplification of the vibration amplitude;

- at a critical voltage level, the sensor sends a command to the car computer to change the ignition timing;

- the engine management system regulates the fuel supply and reduces the time interval before ignition;

- as a result of the operations performed, the operation of the engine comes to a normal state, control over the combustion of the air-fuel mixture is restored.

What are knock sensors

Fuel knock sensors are resonant and broadband.

Broadband sensors are the most widespread, it is their design and principle of operation that have been described in this article. Outwardly, they look rounded, in the center they have a hole for attaching to the engine.

Resonance sensors have an external resemblance to oil pressure sensors, they have a threaded fitting mount. They fix not vibration, but the intensity of microexplosions inside the combustion chamber. After detecting microexplosions, the controller receives a signal from the sensor. The microexplosion frequency index for each motor is different and depends mainly on the size of the pistons.

Basic sensor malfunctions

As a rule, when the sensor is not working, the “Check Engine” indicator lights up on the dashboard of the car. This indicator can light continuously or intermittently light up and go out depending on the load level. A faulty knock sensor is not a hindrance to the operation of the engine, but will not be able to warn the driver about the occurrence of detonation and start the mechanism for its elimination.

There are several possible signs that the knock sensor is bad:

- the engine overheats very quickly, even if the outside temperature is low;

- a noticeable deterioration in the power and dynamics of the car in the absence of any malfunction signals;

- increase in fuel consumption without obvious reasons;

- the occurrence of large soot on spark plugs.

Do-it-yourself knock sensor check

If one of the likely signs of a malfunction of the knock sensor has been found, its performance should be checked. It is recommended to have the knock sensor checked at a service center, but if you don't have the time or motivation to do so, you can check the knock sensor yourself.

First you need to prepare the multimeter by setting the test resistance on it - about 2 kOhm. Next, you should connect the device to the sensor and measure the operating resistance. Without turning off the device, lightly tap something hard on the surface of the sensor housing. If at the same time you can see an increase in the resistance value, then the sensor is normal.

The fuel knock sensor has a small but important role in controlling the operation of an automobile engine. The smoothness of the ride, power and dynamics of the car depends on the operation of the sensor. A faulty sensor is easy to diagnose and, if necessary, replace it yourself.