Contactless ignition system

Content

The ignition system in a car is needed in order to ignite the air-fuel mixture that has entered the engine cylinder. It is used in power units that run on gasoline or gas. Diesel engines have a different operating principle. They use exclusively direct fuel injection (for other modifications of fuel systems, read here).

In this case, a fresh portion of air is compressed in the cylinder, which in this case heats up to the ignition temperature of diesel fuel. The moment the piston reaches top dead center, the electronics sprays fuel into the cylinder. Under the influence of high temperature, the mixture ignites. In modern cars with such a power unit, a CommonRail type fuel system is often used, which provides different modes of fuel combustion (it is described in detail in another review).

The work of the gasoline unit is carried out in a different way. In most modifications, due to the low octane number (what it is, and how it is determined, is described here) gasoline ignites at lower temperatures. Although many premium cars can be fitted with direct injection powertrains that run on gasoline. In order for a mixture of air and gasoline to ignite with less compression, such an engine works in conjunction with an ignition system.

Regardless of how fuel injection and system design are implemented, the key elements in the SZ are:

- Ignition coil (in more modern car models there may be several of them), which creates a high voltage current;

- Spark plug (basically one candle relies on one cylinder), to which electricity is supplied at the right time. A spark is formed in it, igniting the VTS in the cylinder;

- Distributor. Depending on the type of system, it can be mechanical or electronic.

If all ignition systems are divided into types, then there will be two. The first is contact. We have already spoken about her in a separate review... The second type is contactless. We will just focus on it. We will discuss what elements it consists of, how it works, and also what kind of malfunctions there are in this ignition system.

What is a contactless car ignition system

On older vehicles, a system is used in which the valve is of the contact transistor type. When at a certain moment the contacts are connected, the corresponding circuit of the ignition coil closes, and a high voltage is formed, which, depending on the closed circuit (the distributor cover is responsible for this - read about it here) goes to the corresponding candle.

Despite the stable operation of such a SZ, over time it needed to be modernized. The reason for this is the inability to increase the energy required to ignite the VST in more modern motors with increased compression. In addition, at high speeds, the mechanical valve does not cope with its task. Another disadvantage of such a device is the wear of the contacts of the breaker-distributor. Because of this, it is impossible to fine-tune and fine-tune the ignition timing (earlier or later) depending on the engine speed. For these reasons, the contact type SZ is not used on modern cars. Instead, a contactless analogue is installed, and an electronic system came to replace it, about which read in more detail here.

This system differs from its predecessor in that in it the process of forming an electric discharge to the candles is no longer provided by a mechanical, but by an electronic type. It allows you to adjust the ignition timing once, and not change it practically throughout the entire working life of the power unit.

Thanks to the introduction of more electronics, the contact system has received a number of improvements. This makes it possible to install it on the classics, in which the KSZ was previously used. The signal for the formation of a high-voltage pulse has an inductive type of formation. Due to inexpensive maintenance and economy, BSZ demonstrates good efficiency on atmospheric engines with a small volume.

What is it for and how it happens

To understand why the contact system had to be changed to a contactless one, let us touch a little on the principle of operation of an internal combustion engine. A mixture of gasoline and air is supplied at the intake stroke when the piston moves to bottom dead center. The intake valve then closes and the compression stroke begins. In order for the motor to achieve maximum efficiency, it is extremely important to determine the moment when you need to send a signal to generate a high-voltage pulse.

In contact systems in the distributor, during the rotation of the shaft, the breaker contacts are closed / opened, which are responsible for the moment of energy accumulation in the low-voltage winding and the formation of high-voltage current. In the non-contact version, this function is assigned to the Hall sensor. When the coil has formed a charge, when the distributor contact is closed (in the distributor cover), this pulse goes along the corresponding line. In normal mode, this process takes enough time for all signals to go to the contacts of the ignition system. However, when the engine speed rises, the classic distributor starts to work unstably.

These disadvantages include:

- Due to the passage of high voltage current through the contacts, they begin to burn. This leads to the fact that the gap between them increases. This malfunction changes the ignition timing (ignition timing), which negatively affects the stability of the power unit, makes it more voracious, since the driver has to press the gas pedal to the floor more often to increase dynamism. For these reasons, the system needs periodic maintenance.

- The presence of contacts in the system limits the amount of high voltage current. In order for the spark to be "fatter", it will not be possible to install a more efficient coil, since the transmission capacity of the KSZ does not allow a higher voltage to be applied to the candles.

- When the engine speed rises, the distributor contacts do not just close and open. They start banging against each other, which causes a natural rattling. This effect leads to uncontrolled opening / closing of contacts, which also affects the stability of the internal combustion engine.

The replacement of the distributor and breaker contacts with semiconductor elements that operate in a non-contact mode helped to partially eliminate these malfunctions. This system uses a switch that controls the coil based on signals received from a proximity switch.

In the classic design, the breaker is designed as a Hall sensor. You can read more about its structure and principle of operation. in another review... However, there are also inductive and optical options. In the "classic", the first option is established.

Contactless ignition system device

The BSZ device is almost identical to the contact analogue. An exception is the type of breaker and valve. In most cases, a magnetic sensor operating on the Hall effect is installed as a breaker. It also opens and closes the electrical circuit, generating the corresponding low-voltage pulses.

The transistor switch responds to these pulses and switches the coil windings. Further, the high-voltage charge goes to the distributor (the same distributor, in which, due to the rotation of the shaft, the high-voltage contacts of the corresponding cylinder are alternately closed / opened). Thanks to this, a more stable formation of the required charge is provided without losses at the contacts of the breaker, since they are absent in these elements.

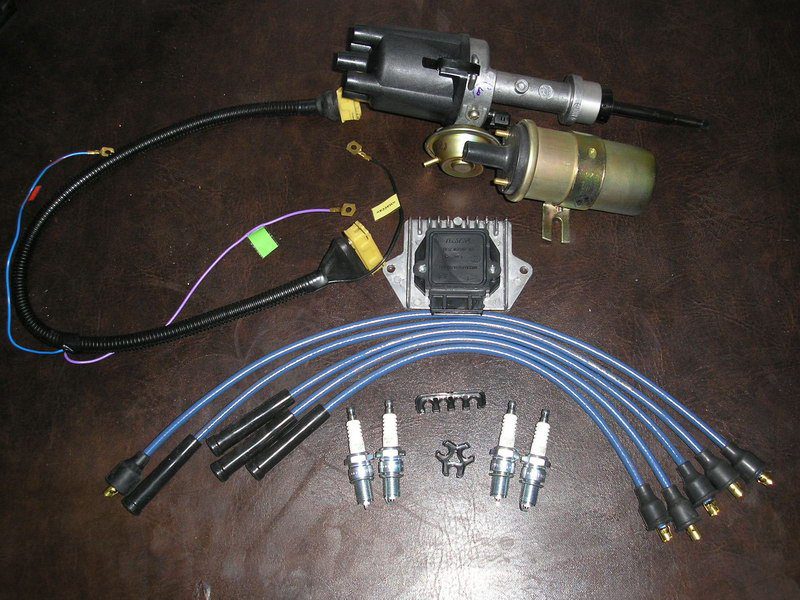

In general, the circuit of a contactless ignition system consists of:

- Power supply (battery);

- Contact group (ignition lock);

- Pulse sensor (performs the function of a breaker);

- Transistor switch that switches the short circuit windings;

- Ignition coils, in which, due to the action of electromagnetic induction, a 12-volt current is converted into energy, which is already tens of thousands of volts (this parameter depends on the type of SZ and the battery);

- Distributor (in BSZ, the distributor is somewhat modernized);

- High-voltage wires (one central cable is connected to the ignition coil and the central contact of the distributor, and 4 already go from the distributor cover to the candlestick of each candle);

- Spark plugs.

In addition, to optimize the ignition process of the VTS, the ignition system of this type is equipped with a UOZ centrifugal regulator (operates at increased speeds), as well as a vacuum regulator (triggered when the load on the power unit increases).

Let's consider on what principle the BSZ works.

The principle of operation of the contactless ignition system

The ignition system starts by turning the key in the lock (it is located either on the steering column or next to it). At this moment, the on-board network is closed, and current is supplied to the coil from the battery. In order for the ignition to start working, it is necessary to make the crankshaft rotate (through the timing belt, it is connected to the gas distribution mechanism, which in turn rotates the distributor shaft). However, it will not rotate until the air / fuel mixture is ignited in the cylinders. A starter is available to start all cycles. We have already discussed how it works. in another article.

During forced rotation of the crankshaft, and with it the camshaft, the distributor shaft rotates. The Hall sensor detects the moment when a spark is needed. At this moment, a pulse is sent to the switch, which turns off the primary winding of the ignition coil. Due to the sharp disappearance of the voltage in the secondary winding, a high voltage beam is formed.

Since the coil is connected by a central wire to the distributor cap. Rotating, the distributor shaft simultaneously turns the slider, which alternately connects the central contact with the contacts of the high-voltage line going to each individual cylinder. At the moment of closing the corresponding contact, the high voltage beam goes to a separate candle. A spark is formed between the electrodes of this element, which ignites the air-fuel mixture compressed in the cylinder.

As soon as the engine starts, there is no longer the need for the starter to work, and its contacts must be opened by releasing the key. With the help of a return spring mechanism, the contact group returns to the ignition on position. Then the system works independently. However, you should pay attention to a couple of nuances.

The peculiarity of the operation of an internal combustion engine is that the VTS does not burn out instantly, otherwise, due to detonation, the engine would quickly fail, and it takes several milliseconds to do this. Different crankshaft speeds can cause ignition to start too early or too late. For this reason, the mixture must not be ignited at the same time. Otherwise, the unit will overheat, lose power, unstable operation, or detonation will be observed. These factors will manifest themselves depending on the load on the engine or the crankshaft speed.

If the air-fuel mixture ignites early (large angle), then the expanding gases will prevent the piston from moving on the compression stroke (in this process, this element already overcomes serious resistance). A piston with a lower efficiency will perform a working stroke, since a significant part of the energy from the burning VTS has already been spent on resistance to the compression stroke. Because of this, the power of the unit drops, and at low speeds it seems to "choke".

On the other hand, setting fire to the mixture at a later moment (small angle) leads to the fact that it burns out throughout the entire working stroke. Because of this, the engine heats up more, and the piston does not remove the maximum efficiency from the expansion of gases. For this reason, late ignition significantly reduces the power of the unit, and also makes it more voracious (in order to ensure dynamic movement, the driver will have to press the gas pedal harder).

To eliminate such side effects, each time you change the load on the engine and the crankshaft speed, you need to set a different ignition timing. In older cars (those that did not even use a distributor), a special lever was installed for this purpose. The setting of the required ignition was done manually by the driver himself. To make this process automatic, the engineers developed a centrifugal regulator. It is installed in the distributor. This element is a spring loaded weights associated with the breaker base plate. The higher the revolutions of the shaft, the more the weights diverge, and the more this plate turns. Due to this, an automatic correction of the moment of disconnection of the primary winding of the coil occurs (increase in SPL).

The stronger the load on the unit, the more its cylinders are filled (the more the gas pedal is pressed, and a larger volume of VTS enters the chambers). Because of this, the combustion of a mixture of fuel and air occurs faster, as with detonation. In order for the engine to continue to produce maximum efficiency, the ignition timing must be adjusted downward. For this purpose, a vacuum regulator is installed on the distributor. It reacts to the degree of vacuum in the intake manifold, and accordingly adjusts the ignition to the load on the engine.

Hall sensor signal conditioning

As we have already noticed, the key difference between a contactless system and a contact system is the replacement of a breaker with contacts with a magnetoelectric sensor. At the end of the XNUMXth century, physicist Edwin Herbert Hall made a discovery, on the basis of which the sensor of the same name works. The essence of its discovery is as follows. When a magnetic field begins to act on a semiconductor along which an electric current flows, an electromotive force (or transverse voltage) appears in it. This force can only be three volts lower than the main voltage that acts on the semiconductor.

The Hall sensor in this case consists of:

- Permanent magnet;

- Semiconductor plate;

- Microcircuits mounted on a plate;

- A cylindrical steel screen (obturator) mounted on the distributor shaft.

The principle of operation of this sensor is as follows. While the ignition is on, current flows through the semiconductor to the switch. The magnet is located on the inside of the steel shield, which has a slot. A semiconductor plate is installed opposite the magnet on the outside of the obturator. When, during the rotation of the distributor shaft, the screen cut is between the plate and the magnet, the magnetic field acts on the adjacent element, and a transverse stress is generated in it.

As soon as the screen turns and the magnetic field stops acting, the transverse voltage disappears in the semiconductor wafer. The alternation of these processes generates corresponding low-voltage pulses in the sensor. They are sent to the switch. In this device, such pulses are converted into a current of the primary short-circuit winding, which switches these windings, due to which a high voltage current is generated.

Malfunctions in the contactless ignition system

Despite the fact that the contactless ignition system is an evolutionary version of the contact one, and the disadvantages of the previous version are eliminated in it, it is not completely devoid of them. Some malfunctions characteristic of the contact SZ are also present in the BSZ. Here is some of them:

- Failure of spark plugs (for how to check them, read separately);

- Breakage of the winding wiring in the ignition coil;

- Contacts are oxidized (and not only the contacts of the distributor, but also high-voltage wires);

- Violation of insulation of explosive cables

- Faults in the transistor switch;

- Incorrect operation of the vacuum and centrifugal regulators;

- Hall sensor breakage.

Although most malfunctions are the result of normal wear and tear, they often also appear due to the negligence of the motorist himself. For example, a driver can refuel the car with low-quality fuel, violate the routine maintenance schedule, or, in order to save money, carries out maintenance at unqualified service stations.

Of no small importance for the stable operation of the ignition system, as well as not only for the contactless one, is the quality of consumables and parts that are installed when the failed ones are replaced. Another reason for BSZ breakdowns are negative weather conditions (for example, low-quality explosive wires can pierce during heavy rain or fog) or mechanical damage (often observed during inaccurate repairs).

Signs of a faulty SZ are the unstable operation of the power unit, the complexity or even the impossibility of starting it, loss of power, increased gluttony, etc. If this happens only when there is increased humidity outside (heavy fog), then you should pay attention to the high voltage line. The wires must not be wet.

If the engine is unstable at idle (while the fuel system is working properly), then this may indicate damage to the distributor cover. A similar symptom is a breakdown of the switch or Hall sensor. An increase in gasoline consumption can be associated with a breakdown of the vacuum or centrifugal regulators, as well as with incorrect operation of the candles.

You need to search for problems in the system in the following sequence. The first step is to determine if a spark is generated and how effective it is. We unscrew the candle, put on the candlestick and try to start the motor (the mass electrode, lateral, must be leaned against the engine body). If it is too thin or not at all, repeat the procedure with a new candle.

If there is no sparking at all, it is necessary to check the electrical line for breaks. An example of this would be oxidized wire contacts. Separately, it should be reminded that the high-voltage cable must be dry. Otherwise, the high voltage current may break through the insulating layer.

If the spark disappeared only on one candle, then a gap occurred in the interval from the distributor to the NW. The complete absence of sparking in all cylinders may indicate a loss of contact on the center wire going from the coil to the distributor cover. A similar malfunction may be the result of mechanical damage to the distributor cap (crack).

Advantages of contactless ignition

If we talk about the advantages of BSZ, then, compared to the KSZ, its main advantage is that, due to the absence of breaker contacts, it provides a more accurate moment of spark formation for igniting the air-fuel mixture. This is precisely the main task of any ignition system.

Other advantages of the considered SZ include:

- Less wear of mechanical elements due to the fact that there are fewer of them in its device;

- More stable moment of formation of a high voltage pulse;

- More accurate adjustment of the UOZ;

- At high engine speeds, the system retains its stability due to the absence of rattling of the breaker contacts, like in the KSZ;

- More fine adjustment of the charge accumulation process in the primary winding and control of the primary voltage indicator;

- Allows you to form a higher voltage on the secondary winding of the coil for a more powerful spark;

- Less energy loss during operation.

However, contactless ignition systems are not without their drawbacks. The most common disadvantage is the failure of switches, especially if they are made according to the old model. Short circuit breakdowns are also common. To eliminate these disadvantages, motorists are advised to purchase improved modifications of these elements, which have a longer working life.

In conclusion, we offer a detailed video on how to install a contactless ignition system:

Questions and answers:

What are the advantages of a contactless ignition system? There is no loss of breaker / distributor contact due to carbon deposits. In such a system, a more powerful spark (fuel burns more efficiently).

What ignition systems are there? Contact and non-contact. The contact can contain a mechanical breaker or a Hall sensor (distributor - distributor). In a contactless system, there is a switch (both a breaker and a distributor).

How to connect the ignition coil correctly? The brown wire (coming from the ignition switch) is connected to the + terminal. The black wire sits on contact K. The third contact in the coil is high-voltage (goes to the distributor).

How does the electronic ignition system work? A low voltage current is supplied to the primary winding of the coil. The crankshaft position sensor sends a pulse to the ECU. The primary winding is turned off, and a high voltage is generated in the secondary. According to the ECU signal, the current goes to the desired spark plug.