Covers for campers and caravans

A car cover is primarily designed to protect the paintwork of the body from the vagaries of the weather. This applies not only to winter, when due to lack of shelter we cover our car for the post-season rest period. In summer, the body is exposed to contamination from bird droppings, which can cause significant damage. The ammonia (NH₃) and uric acid (C₅H₄N₄O₃) they contain are highly corrosive even in low concentrations. Effect? In the case of plastic sandwich panels, aesthetics are lost. Rubber seals show discoloration, dullness, or pitting. In RVs, a chemical reaction occurs on the surface of the sheet metal, causing corrosion spots to form. Polycarbonate materials, such as camping windows, are also susceptible to damage.

In winter, the main enemy of our camper or trailer is air pollution. This is especially noticeable in vehicles parked near industrial enterprises or near houses heated by old-type coal-burning stoves. Particulate emissions combined with temperature fluctuations cause staining and dullness, which ultimately leads to cracked paint peeling. Exposure to solar radiation is also harmful to paint. Prolonged exposure of car seat covers to UV rays causes the snow-white structures to become dull and yellow.

Looking at the list of threats expressed, one might get the impression that the best means of protection would be tight packaging that completely insulates the coating from weather conditions. Oh no. Protective covers are not foil. A sheet fluttering in the wind will stain not only the paint, but also the acrylic windows. A single-layer cover – most often made of nylon – will not work either.

Professional protection must be vapor-permeable and must “breathe,” otherwise our things will literally stew. Under such a dense packing, water vapor will begin to condense, and it is only a matter of time before corrosion spots appear. Therefore, only technical multi-layer fabrics are available - waterproof and at the same time vapor permeable. Only such covers should interest us.

An even bigger challenge for professional case manufacturers is sunlight, which contains a wide range of visible and ultraviolet radiation. This causes unfavorable changes in the properties of polymers and fading of varnishes. Therefore, the best solution is multilayer fabrics with UV filters. The more effective they are, the higher their price will be.

UV filters contained in the multi-layer structure of the material limit exposure to sunlight and at the same time protect the color of our car. Unfortunately, UV radiation, a natural component of solar radiation, also has a damaging effect on the fabric fibers used in the production of protective covers.

The intensity of UV radiation is measured in kLi (kiloangles), i.e. in units expressing how much UV radiation energy reaches one mm³ during a calendar year.

– The protective function of a UV coating depends on the climate zone in which it will be used, but the greatest use of these absorbers will occur in the summer, explains Tomasz Turek, director of the coatings department of Kegel-Błażusiak Trade Sp. z o.o. SP. J. – According to maps showing UV radiation, in Poland we have an average of 80 to 100 kLy, in Hungary there are already about 120 kLy, and in Southern Europe even 150-160 kLy. This is important because products that are poorly protected from UV begin to fall apart faster and literally crumble in your hands. The customer thinks that it is his fault due to incompetent or careless handling of the cover when putting it on or taking it off, but UV rays have a destructive effect on the material.

Given this, it is difficult to assess the durability of such cases. Following the introduction of more powerful and better UV stabilizers, KEGEL-BŁAŻUSIAK TRADE has recently provided a higher warranty of 2,5 years.

Application? Since degradation of the material occurs as a result of exposure to ultraviolet light, those traveling or staying in southern Europe are advised to use a better quality filter. Here's an interesting fact. Under natural conditions, this process takes several years or more. So how do material manufacturers test these filters? Firstly, laboratory methods are used to accelerate the aging of paint coatings by simulating atmospheric conditions. Tests are carried out in climatic, thermal shock, salt and UV chambers. And since it was discovered several decades ago that products located in Florida aged faster than those in other parts of the continent, the peninsula has become a kind of testing ground for accelerated degradation—in this case, of protective fabrics.

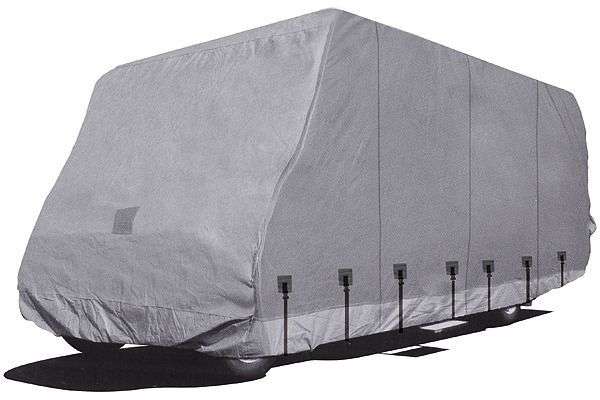

Soft covers made from technical fabrics are designed for both short-term and long-term use - some people can keep their “home on wheels” under such a cover all year round or longer. They are made of difficult-to-water-permeable, highly vapor-permeable materials that ensure proper air circulation inside the case, creating an optimal microclimate for the protected product. Brunner Photos

Creating optimal “cover” for vehicles larger than cars is not an easy task. Only a few companies in Poland specialize in this area.

“We give a 2-year guarantee, although the standard service life of the structure is 4 years,” Zbigniew Nawrocki, co-owner of MKN Moto, tells us. – A UV stabilizer increases the price of products by about ten percent. I will only mention that with an arithmetic increase in the share of UV stabilizer, the final price of the product increases exponentially. Over time, the product will still lose its value, so we recommend parking covered vehicles in shaded areas to slow down this degradation.

Loading a trailer or camper with a cover - given the height of the structure - is not an easy task. While laying the fabric on the roof and then sliding the sides, like a sweater, along the contour of the car body seems like an easy task, with motorhomes this is impossible without ladders, and even adjusting the corners can be quite a challenge. call. Quite often it happens that new models of covers advertised on the market were returned to the manufacturers and the cause of complaints was ruptures - most often in the attachment points of the stabilizing straps, damaged as a result of forceful attempts to stretch the cover. textile.

There is a solution for this. An interesting solution was patented by Pro-Tec Cover, a well-known manufacturer from the UK, which provides a 3-year warranty on its products. The Easy Fit System is nothing more than two poles, only telescopic, which fit into the oarlocks and make it easier to put on the cover. We begin the operation (there are two of us), going from the back of the building to the front. The starting point for the "added height" system was a solution called Duo Cover - a winter cover for caravan storage, but consisting of two parts, with a removable front section guaranteeing unobstructed access to the drawbar and service cover.

Covers for campers and trailers are more functional than those for cars. And it cannot be otherwise. Caravan owners, covering their belongings, do not want to give up the opportunity to have free access to the deck. Therefore, improved market offers have folding sheets, including at the entrance to the development. This solution is a standard in the portfolio of Brunner, a manufacturer of 4-layer winter covers.

In addition to standard sizes, you can, of course, order a custom case. However, it must be remembered that it should not fit the case too tightly or flutter in the wind. Otherwise, the outer material serving as the membrane will be overworked. This is the first vapor-permeable layer that protects against precipitation.

Photo Brunner, MKN Moto, Pro-Tec Cover, Kegel-Błażusiak Trade, Rafal Dobrovolski