What to do if the first gear turns on badly

Content

The process of starting a car from a place and shifting gears is taught in a driving school, and every driver knows how to do it. It doesn’t matter if his car has a manual or one of the varieties of an automatic transmission (automatic transmission). But sooner or later, all boxes begin to fail, which manifests itself in many ways, including difficult gear shifting.

How to engage first gear without harming the gearbox

To engage the first gear necessary for smooth starting, in the case of a manual gearbox, press the clutch pedal and then move the lever to the appropriate position.

What to do if the lever "rests" and the gear does not want to be switched on - they do not teach in schools. Or they don't pay much attention to it. You will need to refresh your memory of what exactly happens in the car's transmission.

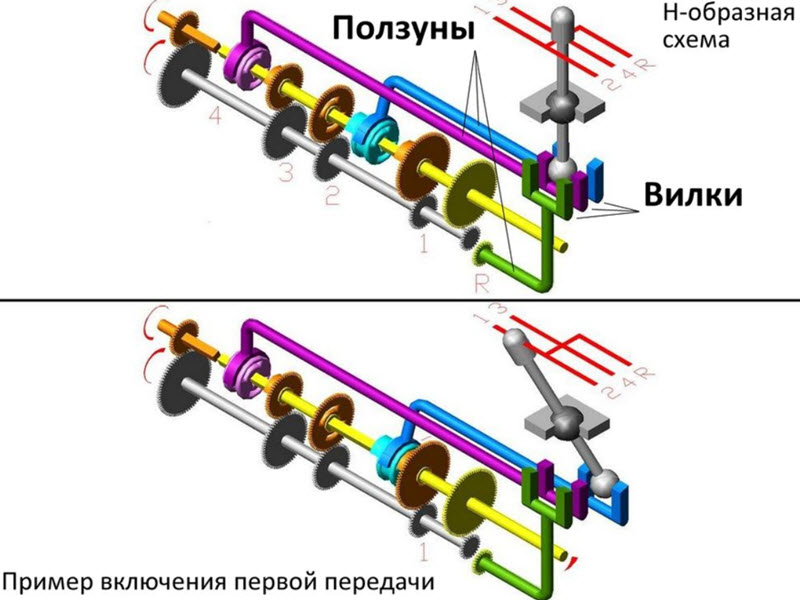

When shifting gears, several processes occur:

- depressing the clutch pedal provides a break in the flow of torque from the engine flywheel to the input shaft of the gearbox, the drive disc releases the driven one, which is normally firmly clamped between it and the flywheel surface;

- the box shaft stops or reduces the speed of rotation, favorable conditions are created for the engagement of the first gear rims;

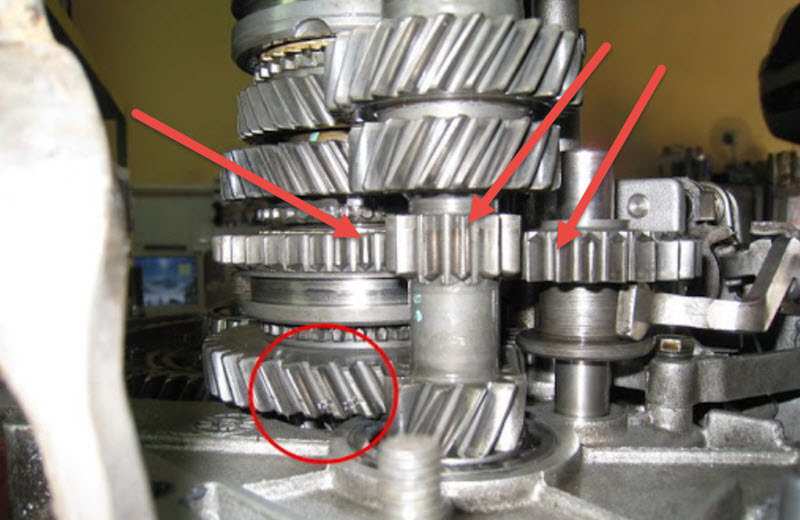

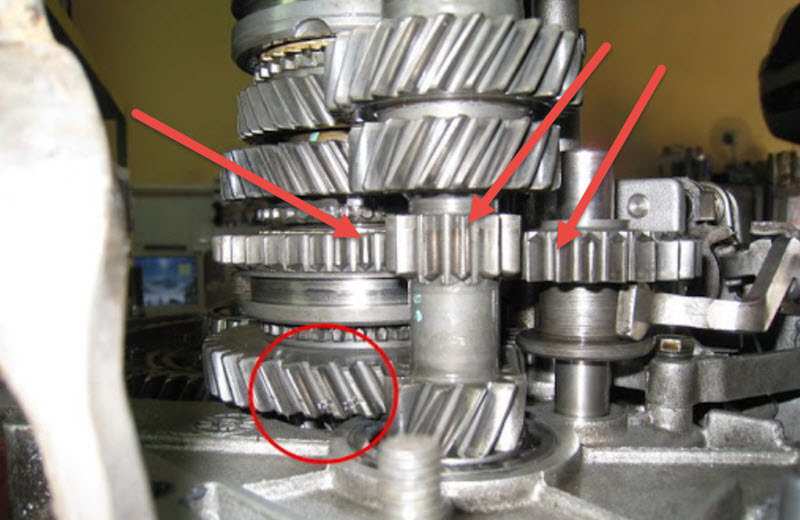

- for complete alignment of speeds, so that the teeth engage without impact and silently, a synchronizer is used - a device that slows down the faster gear of the two involved relative to the second;

- the synchronizer will need some time to fully fulfill its duties, and it depends on the initial difference in rotational speeds, as well as the completeness of the clutch disengagement;

- at the end of the process, the gears are engaged, the speed is turned on, you can release the clutch.

To minimize wear and the likelihood of breakage, several conditions must be met:

- the clutch must be properly adjusted, that is, it must be completely disengaged and not transmit part of the moment due to residual friction;

- it is desirable to reduce the difference in gear speeds, then the load on the synchronizer will be lower;

- do not rush to switch and push the resting lever, there will be a breakdown of the synchronizer with inevitable shock wear.

When the car is at a standstill, you should not add speed before releasing the clutch, as the relative speed of the shafts will increase, you will have to extinguish the excess energy by friction in the synchronizer. Press the accelerator only after turning on the speed.

If the car is rolling, then the opposite effect occurs, the synchronizer will have to accelerate the input shaft, for which it will spend time and part of its resource. You can help him by mastering the technique of regassing. This was taught to truck drivers where not fully synchronized gearboxes are used.

The method of switching "down", that is, for example, from second to first with a moving car, looks like this:

- under the release of gas with a smooth movement, the lever is transferred from the second gear position to neutral, this will not damage the box in any way even without depressing the clutch, you just need not apply force;

- by pressing the accelerator, the revolutions are added to those at which the car would move at a given speed in first gear, plus some margin for the shift time;

- the clutch pedal is pressed quickly and simultaneously, the gas is released, the desired speed is turned on, the clutch is engaged, the gas is added again.

If you understand the principle of operation of the gearbox synchronizers and master the simple method of regassing to automatism, then this will increase the gearbox resource to almost complete wear and tear of the entire car, the box becomes “eternal”. And the clutch with skillful pedaling almost does not wear out.

Causes of interruptions in mechanics

The main problem that prevents you from engaging the gear on a mechanical manual box is the incomplete clutch release for various reasons:

- malfunctions of the mechanical or hydraulic drive from the pedal to the release bearing;

- deformation or the beginning of destruction of the driven disk and its linings;

- curvature of the diaphragm petal spring of the pressure plate (basket);

- pedal not fully depressed by the driver;

- wedging of the input shaft support bearing.

The clutch, as they say, "leads", the rotating shaft of the box does not give in to the efforts of the synchronizer blocking ring. The lever is transferred to the first gear position only with considerable effort, which is accompanied by a crunch and jerk of the entire car.

There may be problems in the box itself. Everything is a little more complicated there, you may have to sort out the mechanism, change the synchronizer clutch assembly and gears. Over time, the shift forks wear out, play appears in the shaft bearings, and the transmission oil poured into the crankcase loses its properties.

Almost all such checkpoints are arranged in approximately the same way, which simplifies the understanding of the principle of operation and the causes of possible problems. The situation is more complicated with "automatic"

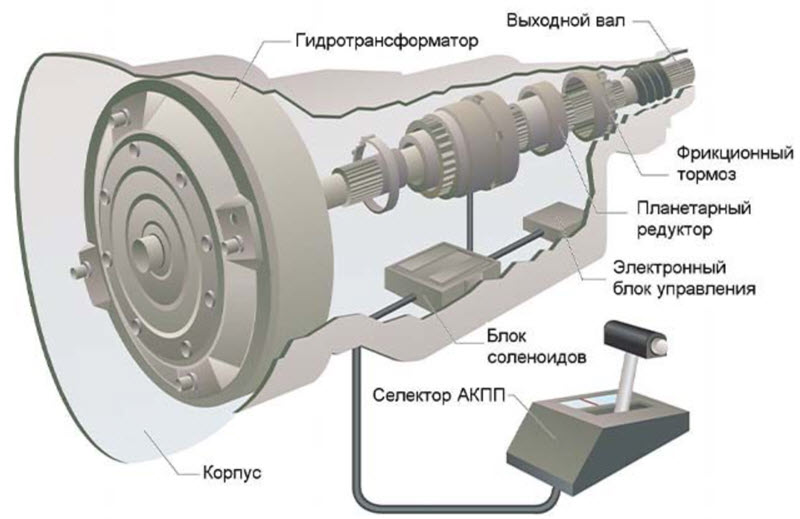

Problems with shifting gears on automatic transmission

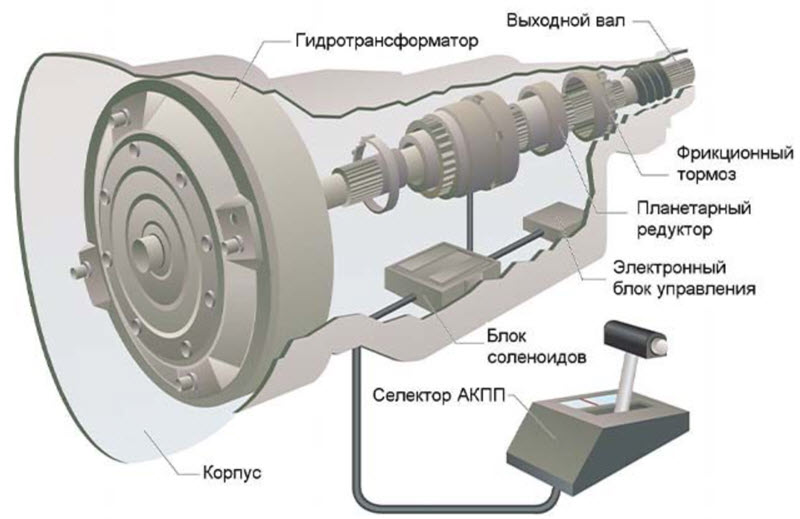

In automatic transmissions, the principle of operation is such that all gears are, as it were, constantly on. The change in the gear ratio in planetary mechanisms is carried out by mutual braking and fixation of some gears relative to others.

For this, friction disc packs are used, some analogues of a clutch, which are pressed by hydraulic pistons.

The necessary control oil pressure in this hydraulic system is created by an oil pump, and distributed by a hydraulic unit with solenoids - electromagnetic valves. They are commanded by an electronic control unit that monitors the readings of its sensors.

Shift failures can occur for various reasons:

- lack of oil pump performance, low pressure;

- malfunction of the solenoids due to clogging, wear or corrosion;

- the oil that serves as the basis of the automatic transmission does not meet the requirements, but it ages and becomes dirty, it is from it that all problems usually arise;

- burnt friction clutches;

- the control unit detected a malfunction and put the box into emergency mode.

As a rule, a classic hydraulic automatic machine will switch to failure many times and will report problems with violations in the operation of various modes, jerks, inadequate gear selection, overheating and error signals. All of this needs to be addressed immediately.

Troubleshooting methods

In the operation of the transmission, everything is determined by preventive measures. It is necessary to change the oil in the units in time, not paying attention to the assurances of the instructions that it is filled there forever. Use lubricating products only of the required categories in terms of tolerances and quality.

Automatic transmissions do not like sports modes, sudden acceleration with the accelerator fully pressed, or slipping of the drive wheels. After such exercises, the oil acquires a characteristic burnt smell, at least it must be replaced immediately along with the filter.

In mechanical transmissions, it is necessary to monitor the condition of the clutch, replace it as soon as the first signs of slipping or incomplete shutdown appear. It is not necessary to apply excess force to the lever, a serviceable box switches easily and silently. The previously described method of regassing is very helpful in ensuring durability.

If the problem still appears in the box, then you should not try to fix it yourself. Gearboxes, both automatic and manual, are quite complex and require not only knowledge, but also experience in repair. They should be carried out by trained specialists in the repair of units with the appropriate equipment.

This is especially true for automatic transmissions, where it is generally pointless to climb with a typical set of motorist tools. Even a simple oil change is different from the same operation for a manual transmission or engine.

An even more delicate device is a CVT automatic transmission. In principle, the variator is simpler, but the practical implementation required many years of development and experimentation. It is naive to think that it can be simply disassembled and repaired. This, with some convention, takes place on low-powered scooters, but not on cars.

For independent execution, only one type of repair can be distinguished - clutch replacement. With limitations, because you should not do this without training on robots and preselective boxes.

Very often, a new clutch will solve the problem of difficult gear shifting when pulling away.