What grease to use for ball joints and steering tips

Content

The development of automotive technology goes along the minimum maintenance vector between routine replacements of components and even entire units. On the one hand, this is similar to the approach used in aviation, where absolute reliability is important, but on the other hand, cars should still not require aircraft maintenance costs. Therefore, sometimes parts are lubricated and even repaired between replacements.

Why lubricate ball joints

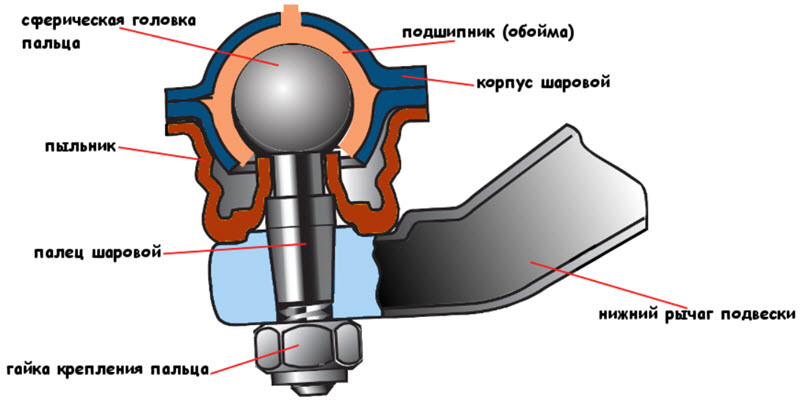

This hinge is a spherical pin that rotates and deviates at specified angles inside the housing. The ball is maximally covered by a plastic insert, sometimes preloaded by a spring to completely eliminate backlash in operation.

When driving, the suspension works continuously, ball joints and steering tips, built on this principle, when they are constantly in motion, experiencing friction with significant pressing forces.

Without high-quality lubrication, even a relatively slippery nylon liner will not withstand. Both the steel of the finger and the liner itself will wear out. A specialized grease, that is, a viscous lubricant, is installed at the factory for the entire life of the hinge.

For some nodes, the service ends there, they have a non-separable design. The support or tip is sealed, the joint is closed with an elastic and durable cover. But a number of products allow penetration under the anther, which allows you to put an additional or repair amount of fresh grease there.

It makes no sense to lubricate the hinge, which has already traveled with a damaged cover. Water and dirt have penetrated into the ball joint, it is impossible to remove them from there. The times of fully collapsible products, when it was even possible to replace the liner, are over. Not a single manufacturer has access to the ball, the product is strictly disposable.

Even if it is possible to remove and replace the anther, some hinges provide for its delivery to spare parts, it is unlikely to accurately catch the moment of the very beginning of depressurization. Dirt has already hit and smeared over the friction pair. But putting lubricant into a new product is useful. Usually there is not enough of it, and it is not of the best quality.

Selection Criteria for Lubrication for Ball Joints and Lubricants

The requirements for a lubricating product are general here, there are no special specifics:

- a wide temperature range, from freezing in winter parking to overheating when working in the summer on rough roads and at high speeds;

- complete inertness with respect to rubber or plastic anther;

- the ability to adhere well to metal, enveloping the ball;

- oil film strength under heavy load;

- extreme pressure properties;

- water resistance, it is not always possible to completely eliminate the path of moisture to the finger;

- durability, these nodes have a significant resource.

Strictly speaking, any high-quality universal grease satisfies all these conditions. But one product is always slightly better than another, and drivers often want to use the most suitable, preferably specialized.

Lubricant base

The basis is always the same - these are oils obtained from oil. But it is liquid, and therefore all kinds of thickeners are used. Usually this soap is made from various substances, lithium, calcium, sulfates or barium.

The latter is most suitable for supports, but is rarely used for a number of reasons. Multipurpose greases use lithium and calcium thickeners.

Operating temperature range

The best lubricants work from -60 to +90 degrees. This is not always so necessary, so the lower limit can be at -30. But this is unlikely to suit residents of regions where severe frosts occur, so we can talk about the choice for a particular area.

The degree of intensity of the load

In this regard, all lubricants are approximately the same. Slight deviations in tribological characteristics and welding loads or burrs in relation to ball joints are not relevant.

Price

For many, the price of a product is crucial. Widespread universal lubricants are inexpensive, and their consumption, given the characteristics of the application, is extremely small. Rather, the problem may be the availability of goods.

5 popular lubricants

We can say that they will work equally long and reliably. But there are features.

SHRB-4

Classic grease for ball joints. Developed back in the USSR using Italian technology for FIAT. It was she who was used at factory refueling on VAZ cars.

Features of ShRB-4:

- the best characteristics for the safety of elastic covers;

- high durability;

- exemplary water resistance;

- good tribological and extreme pressure properties;

- wide temperature range;

- acceptable price.

As for accessibility, things are getting worse here. ShRB-4 and its analogues are produced by a few enterprises, but there are many fakes when the most common products of wide application are sold under this brand.

You can distinguish the real one by color and characteristic fibrous consistency. The lubricant stretches like a heated high-quality cheese, while it has a light brown tint. The only one that is produced on a barium thickener. Apparently, due to poor environmental friendliness of production. Purpose - heavily loaded nodes.

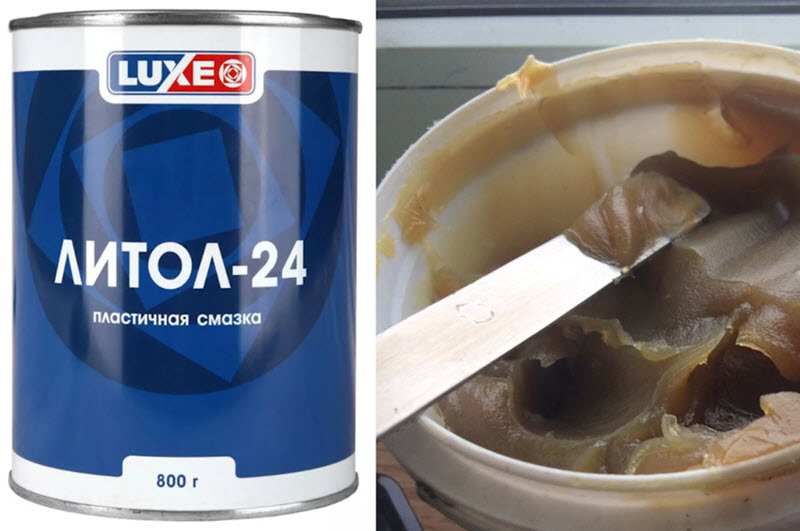

Litol 24

The most versatile grease with lithium soap. Designed for bearings, but also copes well with supports. Low price, good tribology. Satisfactory moisture resistance.

It does not behave very well at low temperatures, we can talk about the border of -40 degrees. But it allows overheating up to +130.

Lubrication is not designed to provide extreme pressure properties, but in passenger cars this is not required for hinges. It can be used for additional filling of covers before installation.

Tsiatim-201

Typical military product with a wide temperature range, designed for short-term use. It does not differ in high water resistance, durability and some special anti-friction properties. It can be used, but it does not compete with specialized products. Lithium thickener.

Liqui Moly

Expensive and high-quality materials from a well-known company. They work great, but are quite expensive. Different specific products have different properties, but in general, indicators can be selected with the highest bar for individual characteristics.

It will be the best choice for connoisseurs of beauty, ready to pay for it. But there is no particular need for such a choice, other lubricants will work just as well, and extreme conditions for supports and tips are not expected.

Grease Calcium

Lubricants based on calcium sulfonates have a number of fundamental advantages. This is a very high limit for heating, water resistance and metal protection. The main drawback is that they do not work in severe frosts; they can only be used in the southern regions.

However, the inertness with respect to water, the atmosphere and the rubber of the covers can justify the high price. This is the very product that can be considered elite, albeit with significant drawbacks.

How to properly lubricate tips and ball joints

It is impossible to lubricate the ball and the liner, and there is no need for this, the lubrication is already there. Therefore, before installing the part, the cover is carefully separated, if this is structurally possible, and a certain amount of lubricant is placed under it by about a third of the volume.

You can’t hammer too much under the anther, during operation it will become very deformed and lose tightness, and the excess will still be squeezed out. There must be a significant air cushion.

It is enough just to cover the protruding surface of the ball with a layer of about a few millimeters. During operation, the required amount will be drawn into the gap, and the remaining will protect the friction pair from the environment and become a kind of reserve.

The same can be done if you notice a crack in the anther in time and find a replacement for it. On one condition - there should not yet be dust and water under the anther, otherwise it is useless and unsafe to lubricate the part. The hinge is inexpensive, and the operations for replacing the assembly assembly and lubrication are the same.