What to do if the car pulls to the side when braking

Content

- The brakes on one of the wheels do not work.

- The piston of one of the wheel cylinders is stuck in the maximum extended position.

- There is an air lock in the hydraulics of the brake system.

- Violation of the tightness of the hydraulic system.

- The braking system is generally good, but one of the wheels does not brake properly.

Spontaneous deviation of the machine from rectilinear motion is a fairly common problem. The car can pull to the right or to the left when the driver simply drives at a constant speed and does not turn the steering wheel. Or the car pulls to the side during braking. In such situations, the controllability of the vehicle worsens, it becomes tiring to drive a car, since every now and then you have to adjust the steering wheel. And besides, the risk of driving into the oncoming lane or being in a ditch increases.

The reasons for this behavior of the car can be different. It happens that they are very commonplace and easily fixed. It happens that the help of a specialist is required to identify and fix the breakdown. Often the causes lie in the wheels or suspension, but often the vehicle is pulled to the side due to problems in the brake or steering system. It is these systems that are most critical in terms of driving safety, and therefore any symptoms that indicate possible breakdowns in them must be taken very seriously.

Before climbing into the wilds, it is worth starting with simple things.

First you need to clearly define in what conditions and in what situations the car is blown to the side.

Often the road slopes to the right, and this can cause a deviation from a straight line, including during braking. To eliminate this factor, you need to find a flat area and diagnose the behavior of the machine on it.

It happens that there is a track on the road surface, which affects the direction of movement. The track often affects coasting, but it happens that it can lead to skidding when braking. This factor also needs to be diagnosed.

Diagnose the tire pressure and equalize it. Often this solves the problem.

Next, you should drive the car into an inspection pit or use a lift and inspect the suspension elements and look for obvious problems - leaking brake fluid, poorly tightened clamps on the fittings, mechanical defects, loose bolts securing the hub, parts and steering mechanism.

If no obvious malfunctions are found, a more thorough search for the causes should begin.

When the car veers to the side while braking, the first place to look for trouble is in the brake system. Most often, the reason lies in one of the wheels or there is a problem with the hydraulics, due to which the pressure in the system drops and the cylinder piston cannot press the pad against it effectively enough. When there are differences in the operation of the brakes on the right and left, then when braking, a pull to the side occurs. The car deviates in the direction from which the pads are pressed harder against the disc.

Both the front and rear brakes affect the car's pull to the side, although the rear brakes are less so. Handbrake should also not be ruled out as a suspect.

In the braking system, 5 situations can be distinguished in which braking will be accompanied by a deviation from rectilinear motion.

The brakes on one of the wheels do not work.

The brake pads are not pressed against the disc, the wheel continues to rotate, while the opposite one is slowed down. The side on which the wheel is still spinning goes forward, and as a result, the car turns around, and quite strongly. For example, if the brake mechanism on the right front wheel does not work, the car will skid to the left during braking.

A similar situation will be observed in the case when the brake on one of the rear wheels does not work, only the deviation will be less significant.

Possible reasons for the failure of the wheel brake cylinder:

the piston is stuck in its original position and the pad is not pressed against the disc;

in a design with a floating bracket, the guide pin may jam;

there is an air lock in the hydraulic system that prevents the creation of sufficient pressure to extrude the piston from the cylinder;

depressurization of hydraulics, due to which the working fluid flows out;

too old. Over time, TJ absorbs moisture and can boil at a lower temperature. In this case, strong local heating during sudden braking can cause boiling of the fuel oil and the formation of a vapor lock;

the rubber brake hose is worn out and swells when the brake pedal is pressed, and the TJ pressure practically does not reach the wheel cylinder. This hose needs to be replaced.

The piston of one of the wheel cylinders is stuck in the maximum extended position.

The sliding caliper guide pin can also jam. The result will be the same.

In this case, the pad is constantly pressed against the brake disc and the wheel is constantly braked. In such a situation, at the first moment of braking, the car will be thrown a little in the direction from which the jammed mechanism is located. further, when the braking force on the opposite wheel is equal, the car will continue to brake in a straight line.

Other obvious signs can also indicate a piston or caliper jamming in the working position:

deviation of the machine from rectilinear movement due to braking of one of the wheels;

the rattle of the pad rubbing against the brake disc;

strong heating of the brake disc due to constant friction. Carefully! Do not touch the drive with bare hands when you are diagnosing it. Severe burn possible;

It happens that the steering wheel vibrates.

Typical causes of piston seizure:

corrosion due to ingress of water and dirt. This usually happens when the anther is damaged;

old, dirty brake fluid;

piston deformation. This often happens when the pads are worn to the limit or the disc is excessively worn. In order to press the pads that have become thin to the disc, the piston has to move further out of the cylinder, and at the time of braking it is subjected to a serious bending load.

If the brake mechanism is jammed, it must be disassembled, cleaned, and worn parts replaced.

The piston should be cleaned of dirt, dried grease and traces of corrosion, and then sanded. The same should be done with the inner surface of the cylinder. If there are significant deformations, scoring, deep scratches, the correct operation of the brake cylinder is impossible, in this case, only replacement remains.

The weak point of the floating caliper brake mechanism is the guide pins along which the caliper moves. They are the ones most likely to be the culprit. The reasons are dirt, corrosion, old, thickened grease or its absence. And this happens due to a damaged anther and irregular maintenance of the mechanism.

Caliper guides and holes for them also need to be well cleaned and sanded. Make sure that the guides are not deformed, otherwise replace them.

Lubricate the piston and guides with grease specifically designed for calipers.

After the repair is completed, diagnose the brake fluid level and bleed the system.

There is an air lock in the hydraulics of the brake system.

When you press the brake pedal, the air will be compressed, and the effect on the brake fluid will be minimal. The brake mechanisms in this circuit will not work or the braking force will be insufficient.

The braking distance will increase, and the car may pull slightly to the side when braking. The deviation from rectilinear movement due to air in the hydraulics is not as pronounced as in the case of jamming of one of the pistons in its original position.

A soft brake pedal is another sign of air in the system.

The treatment is obvious - pumping hydraulics and removing air from it.

Violation of the tightness of the hydraulic system.

When the tightness of the hydraulic system of the brake system is broken, the working fluid may flow out, this will be indicated by a drop in the level of the brake fluid. This malfunction is often accompanied by a hiss when the brake pedal is pressed. Often, hissing can be clearly heard if you press the pedal immediately after the engine stops. You can find the leak by carefully inspecting the system. Traces of brake fluid can be on parts, pipes, or on the ground.

The most typical leak locations are:

cracked hose or rusted metal tube;

leakage at the points of connection of hoses to fittings due to insufficiently crimped clamps;

working brake cylinder if the cuff installed inside is damaged.

To restore the tightness of the system, replace damaged hoses and tubes and tighten the clamps securely.

The brake cylinder can be repaired using a repair kit. If this is not possible, then the brake assembly will have to be replaced.

The braking system is generally good, but one of the wheels does not brake properly.

The behavior of the machine during braking is similar to the case when one of the wheel cylinders does not work.

Possible reasons:

badly worn brake pads. The greater the difference in the degree of wear of the pads of the right and left wheels, the more the car will deviate to the side;

the brake disc of one of the wheels is badly worn or deformed;

oil, water or other substance that greatly reduces the coefficient of friction has got between the pads and the disc.

The problem is solved by thorough cleaning and replacement of worn pads and discs. They must be changed at the same time on both wheels of the same axle.

If there are no problems with the brakes, but the car still skids to the left or right while braking, then you will have to continue looking for a breakdown, considering less likely causes.

- Wheels

In addition to the difference in tire pressure, some other wheel problems can also cause the car to deviate from a straight line during braking:

wheels are unbalanced;

one of the tires has a defect, a hernia, etc.;

tires of different types are installed on the same axle;

tires with a directional tread pattern are incorrectly installed;

uneven wear of tires on the left and right, especially on the front wheels. This happens as a result of a seasonal change of tires, when one of the tires of the rear pair, which usually wears out less, is put on the front axle. To avoid this, the marking of the tires removed for storage will allow.

- Camber / Convergence

Incorrect wheel alignment can pull the car to the side during braking. For example, with a simultaneous significant deviation from the norm of the camber angle and the angle of the longitudinal inclination of the axis of rotation (caster), braking may be accompanied by a deviation from a straight line.

- Significant backlash or wedging.

At the same time, it can pull to the side not only during braking, but also during normal rectilinear movement. Wheel bearing problems are often accompanied by a hum that can change in tone and volume depending on speed.

rear axle stabilizer bar defect.

Unequal wear of the front suspension springs. It is worth diagnosing other suspension elements - ball bearings, silent blocks.

Different loading of the machine on the left and right side.

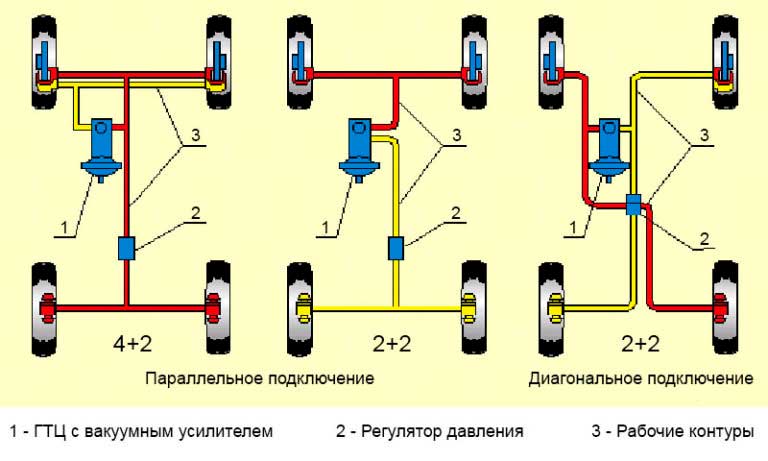

Malfunction of the anti-lock braking system or the brake force regulator, which is often called the "sorcerer".

Steering rack, rods and tips. The probability that the reason lies precisely here is small, but this option cannot be ruled out.