What is a gear box

Habitually manipulating the gearshift lever, the driver hardly thinks about how the mechanism that shifts the gearbox from one gear to another is activated. There is no particular need for this as long as everything works like clockwork. But when problems arise, motorists begin to “dig” for information, and then the word CULISA pops up.

It is impossible to give an exact and exhaustive definition of the concept of a gearbox linkage, since there is simply no such unit in a car. You will not find this term in the manuals for the operation and repair of cars or other technical documentation.

To be more precise, the backstage. It happens that they call the thrust of the gearbox drive mechanism. And this is the only technically justified use of the word “scene” in relation to an automobile transmission or.

However, when they talk about the backstage of the checkpoint, they usually mean something completely different. Conventionally, we can say that this is a set of levers, rods and other parts, through which the driver's movement of the lever in the cab is converted into gear shifting in the box. It would be more correct to talk about the gear shift mechanism drive. But the drive includes a number of parts located inside the gearbox, and the backstage is most often called what is between the lever in the cabin and the body.

When the lever is placed on the box itself, the entire mechanism is completely inside the gearbox, and the effect on the gearshift forks comes from the lever directly without intermediate components. Switching is clear, however, this design requires additional space on the floor of the cabin. This option is rare in modern models.

If the box is located at some distance from the driver, you have to use a remote drive, which is commonly called the backstage. This is exactly the case in models in which the internal combustion engine is located transversely, and almost all cars produced in our time are like that.

Due to the use of a remote drive, the tactile clarity of the gear engagement is reduced and the force that needs to be applied to the shift lever increases. In addition, the rocker requires maintenance and lubrication.

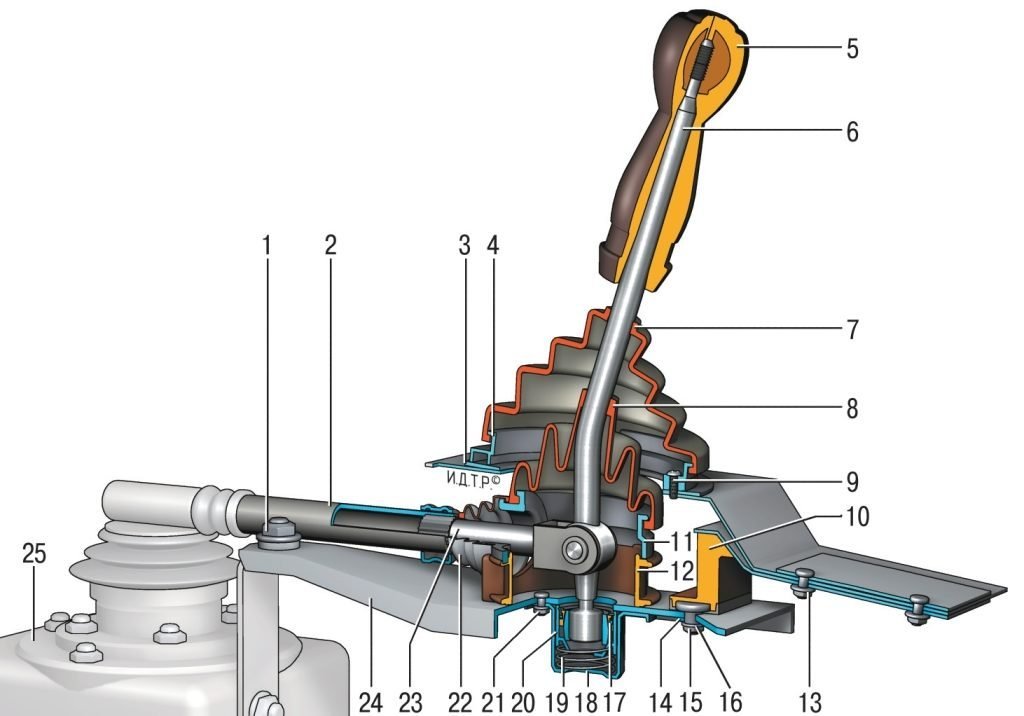

The image below shows a diagram of the gear shift mechanism drive (backstage) Chery Amulet A11.

- gear shift knob;

- sleeve;

- gear shift lever;

- spring;

- ball joint ball;

- elastic cylindrical pin;

- fixing cover of the ball joint;

- separating sleeves;

- lower plate of the ball joint (well);

- gear shift housing;

- bolts M8x1,25x15;

- guide plate;

- guide plate bushings;

- polyamide locking nut;

- thrust sleeve;

- traction ("scene").

The design of the gearbox backstage is not regulated by anything, each manufacturer can make it the way it considers necessary, depending on the specific layout of the machine and the location of the gearbox and other components of the transmission.

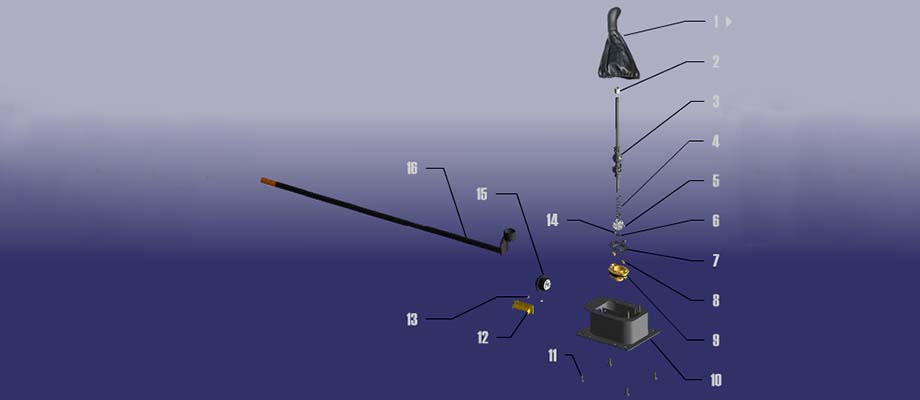

Instead of rigid traction (16), the so-called Bowden cable is now increasingly used. It is made of steel and is covered with a flexible plastic jacket on top, which ensures the mobility of the cable and protects against corrosion, which is important for the part that is located under the bottom of the body.

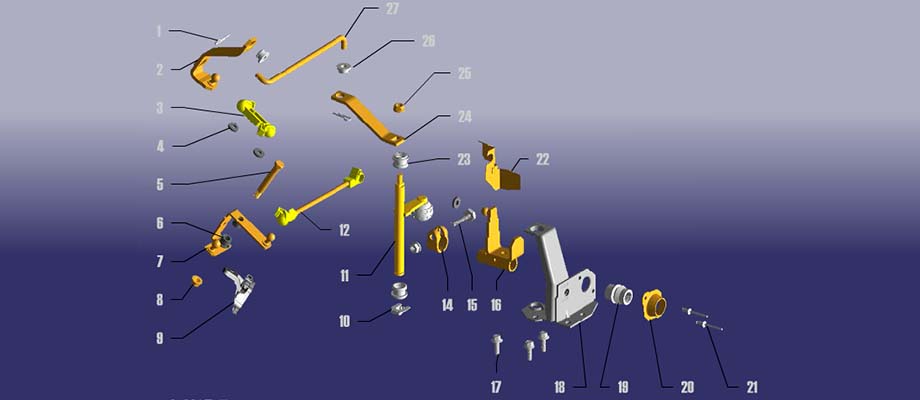

A diagram of the gear selection mechanism located inside the gearbox is shown in the following image.

- cotter pins;

- lever arm;

- coupling traction;

- sealing rings;

- bolt;

- bushings;

- gear selection lever;

- lock nut;

- ICE pillow bracket;

- retainer;

- gear shift shaft with ball;

- traction;

- clamp;

- bolt;

- gear selection lever;

- bolts;

- bracket;

- support sleeve;

- support sleeve cover;

- rivets;

- protective cover;

- bushings;

- intermediate bar;

- lock nut;

- sleeve;

- barbell.

In general, the mechanism under consideration is quite reliable, but it has a lot of moving parts rubbing one against the other. Worn or broken one of the parts can disrupt the normal operation of the entire assembly.

Water and dirt, lack of lubrication and lack of attention from the owner of the machine can have a negative effect on the condition of the backstage. Some drivers pull the shift knob too sharply, and inexperienced motorists do not quite correctly manipulate it and the pedal. This can also lead to premature wear of the gearbox control drive and the box itself.

The checkpoint linkage can signal its breakdown with the following symptoms:

- gear shifting is difficult;

- one of the gears does not turn on or another turns on instead of one;

- extraneous sounds when switching;

- switch lever play.

The looseness of the lever can be ignored for some time. However, as the backlash increases, so does the risk that one day at a crucial moment you simply will not be able to change gear.

In most cases, a motorist of average preparedness will quite cope with the replacement of the backstage assembly. But don't rush. If there are no visible signs of breakdown, it is possible that the gearshift drive setting has simply gone wrong. Adjustment often solves the problem. This procedure can be carried out independently. But you will need to climb under the car, so you need a viewing hole or a lift.

The adjustment is made with the engine off and the parking brake applied. Before carrying out any actions that require the separation of the backstage parts, be sure to mark them so that you can then properly assemble the structure. It must be remembered that even a slight displacement of the components of the mechanism relative to each other can cause noticeable changes in the operation of the drive.

To make the adjustment, you need to loosen the clamp that fastens the gear lever to the linkage (scene) going to the gearbox. Small turns or movements of the lever hub along the rod will change the clarity of selection and engagement of certain gears. After each attempt, tighten the clamp fastening and check what happened.

The following describes how to make adjustments in Chery Amulet. But for other models where the H-algorithm for moving the gearshift lever by the driver is used, the principle is the same. Just keep in mind that some manufacturers have a specific pattern of movement of the lever may be different. For more precise information on adjusting the backstage, look in the repair and maintenance manual for your car model.

To regulate the clarity of the choice of 1st and 2nd gears, you need to slightly turn the lever clockwise (view from the ICE side).

To adjust 5th and reverse gear selection, turn the lever in the opposite direction.

The clarity of the inclusion of the 2nd and 4th speed is regulated by moving the lever along the rod forward in the direction of the machine. It is not necessary to rotate about the axis.

If there are problems with the inclusion of 1st, 3rd, 5th and reverse gears, move the lever back to eliminate them.

Repeat the process until you get the desired result.

If the adjustment did not help, then you need to think about repair. Bushings and ball joints wear out to the greatest extent in the gear shift drive. If there is no good reason to change the assembly, you can purchase a repair kit suitable for your car and replace the problematic parts.

The gearbox link or a repair kit for it, as well as many other spare parts for Chinese, Japanese and European cars can be bought in the online store with delivery in Ukraine.